Masking Tape with Crepe Paper Rubber Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

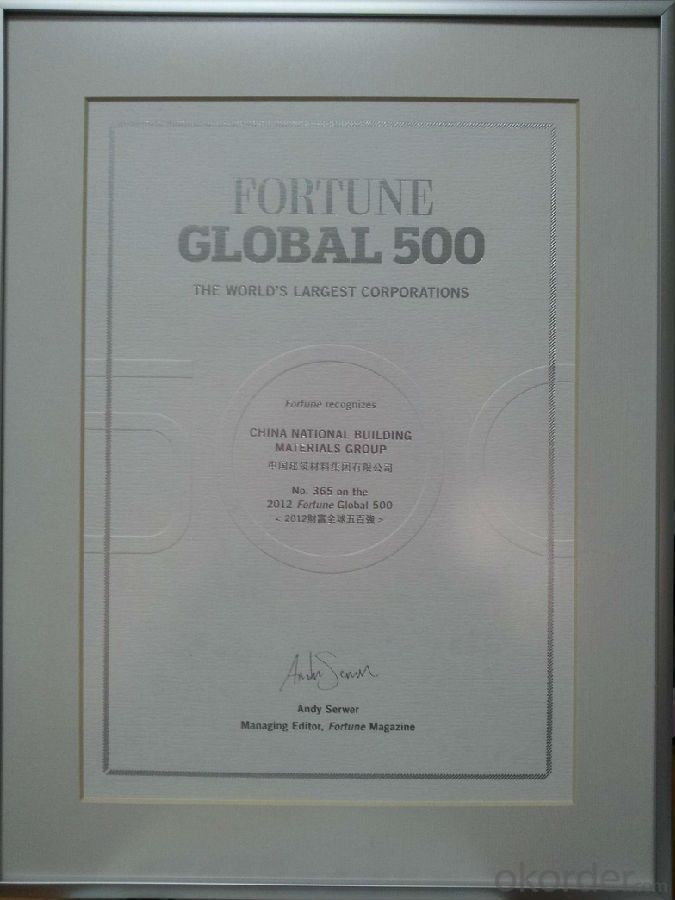

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

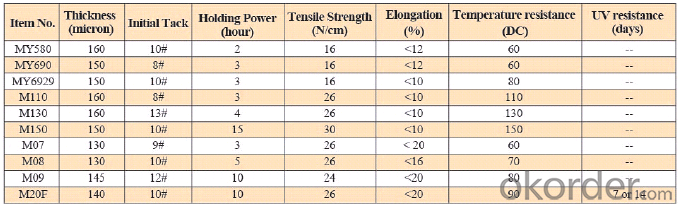

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1800mm; width according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q:Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. Packaging tape is designed to securely seal various types of packaging materials, including plastic clamshell packaging. It provides a strong adhesive bond that holds the clamshell packaging together and prevents it from opening during shipping or handling. Additionally, packaging tape is durable and tear-resistant, ensuring that the clamshell packaging remains sealed and protected throughout the entire distribution process.

- Q:Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q:Are there any eco-friendly options for packaging tape?

- Yes, there are eco-friendly options for packaging tape available. Some alternatives to traditional plastic packaging tape include paper tape, which is made from renewable resources and can be recycled or composted. Another option is water-activated tape, which is also made from paper and uses a natural adhesive activated by water. These eco-friendly packaging tape options help reduce plastic waste and are more sustainable choices for packaging needs.

- Q:Can packaging tape be used for sealing plastic folders?

- Yes, packaging tape can be used for sealing plastic folders.

- Q:Can packaging tape be used for sealing glass jars?

- Indeed, sealing glass jars is possible with packaging tape. However, it should be noted that packaging tape is not specifically designed for this purpose and more suitable alternatives are available. While packaging tape can offer a temporary seal, it may not be as effective in preserving the freshness and airtightness of the jar's contents. Furthermore, the tape may not adhere well to glass surfaces and could peel off over time, potentially compromising the seal. For optimal results in preserving the contents of glass jars, it is recommended to utilize specialized methods and materials such as rubber gaskets, metal lids with screw caps, or heat-sealing techniques.

- Q:Can packaging tape be used for sealing glass bottles?

- Yes, packaging tape can be used for sealing glass bottles. However, it is important to note that it may not provide the same level of security and protection as specialized bottle sealing methods such as corking or using bottle caps. Packaging tape may not be as effective in preventing leakage or maintaining the freshness of the contents.

- Q:Does packaging tape come in different textures?

- Indeed, there is a variety of textures in packaging tape. Although the usual packaging tape is smooth and glossy, there are alternative textures to choose from. For instance, rubberized tapes possess a soft and grippy texture, while paper-based tapes have a rougher texture akin to masking tape. These textured tapes serve specific functions, like offering enhanced grip or adhering to challenging surfaces. Nevertheless, it is vital to recognize that textured packaging tapes may possess diverse adhesive properties and may not be suitable for every application.

- Q:Does packaging tape have a specific weight capacity?

- Yes, packaging tape generally does not have a specific weight capacity as it is primarily used for sealing and securing packages rather than providing structural support.

- Q:Are there any special considerations when using packaging tape for fragile items?

- Yes, there are special considerations when using packaging tape for fragile items. It is recommended to use a high-quality and strong packaging tape specifically designed for fragile items. Additionally, it is important to apply multiple layers of tape to ensure secure and stable packaging. Bubble wrap or foam padding should also be used to provide extra protection and cushioning. Proper labeling indicating the fragile nature of the package is also crucial to alert handlers to exercise caution during handling and transportation.

- Q:Can packaging tape be used for sealing metal boxes?

- Indeed, metal boxes can be sealed using packaging tape. Specifically engineered to create a secure and long-lasting seal on different surfaces, such as metal, packaging tape possesses a powerful adhesive that effectively adheres to metal, guaranteeing that the box stays sealed throughout storage or transportation. Nevertheless, it is crucial to select a packaging tape appropriate for demanding tasks, capable of enduring the weight and pressure that the metal box may experience. Furthermore, it is advised to cleanse the metal surface prior to applying the tape to ensure optimal adhesion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Masking Tape with Crepe Paper Rubber Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords