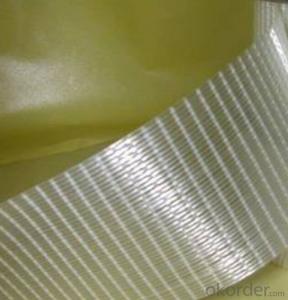

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

FOB Price of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving US $0.22/ Square Meter

MOQ of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving: 10000 Square Meters

Supply Ability of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving: 6000000 Square Meters per Month

Payment Terms of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving: L/C,T/T

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Specifications of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Place of Origin: China (Mainland)

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Brand Name: CMAX

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Application: Wall Materials

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Width: 1M-2M

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Size: 5*5/ INCH

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Weight: 40gsm to 200gsm

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Weave Type: Plain Woven

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Yarn Type: C-Glass

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Alkali Content: Medium

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Standing Temperature: 500℃

Product information of BASF Glue Coated Marble Backing Mesh

Name: Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Use best fiberglass yarn and best glue

Clear and beautiful Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

High strength Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

30 years experience of manufacturing Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Excellent Priced Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

FAQ of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Q: What is Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

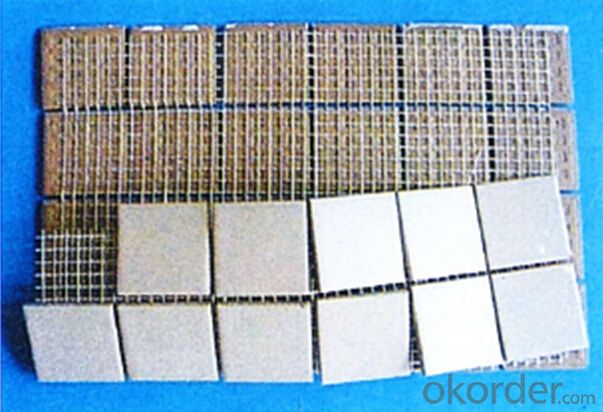

Coated Alkali-resistant Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Weight: 65g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Four years under normal weather conditions and use .

Q: What is the package of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Production periods: 30days for 1X40HQ.

- Q:What is the packet processing method of external wall thermal insulation mesh?

- 1. Before pasting polystyrene board, insulation layer on the cut-off portion should do a flanging mesh, the flanging parts spread on 70mm wide and 2mm thick polymer mortar, and quickly press an edge of 70mm mesh into polymer binding mortal with steel until gushy polymer binding mortal covers the mesh without leakage. 2. The remaining part is of packed for standby application, the length of throwing parts bypassing the end plate of the exposed surface is not less than 100mm, the pasted mesh should take flip or cover and product protection measures.

- Q:What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q:For wall slot, is seam paper tape or anti-cracking mesh suitable for joints?

- Mesh is certainly better.

- Q:Which parts are the professional mesh of external wall thermal insulation alkali resistant used?

- Which parts are the professional mesh of the external wall thermal insulation alkali resistant used? The roofing and the thermal insulation layer. The main function: 1. The resistance to weather can make it bear the various change of stress and make it not crack so as to obtain a long-term water-proofing abilities and avoid the leakage of the roof. 2. Because it is in the insulation layer, the Mesh can improve the mechanical strength and anti-cracking effect of the mesh. And the alkalinity of the plastering mortar has corrosion on the mesh. The mesh through the process of alkali resistant resin coating can keep a good strength retention?rate so as to make the thermal insulation plastering mortar have a better performance of durability and crack?resistance ability.

- Q:What's the difference between window screens and window screens?

- Screen window and window screen refer to a kind of thing, just name different.

- Q:Should the wall shear walls be hung with fibre nets?

- Fiber network, also called reticular fiber, reticulated polypropylene fiber, is a kind of polypropylene as raw material, made by special process. The appearance is a network structure made by mutually crossing the plurality of fiber monofilament.

- Q:What additive does alkali resistant glass fiber gridding cloth has?

- Ore melting status by purification of lower alkali content in wire drawing glass fiber grid cloth weaving to deal with

- Q:Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Yes, that's right. Do two layers of mesh cloth to increase the thickness of the surface layer, improve the anti cracking performance and prevent the rainwater from seeping in. We are now doing a rock wool insulation is done: rock wool board full sticky paste, wire mesh hanging in the 50*50 rock wool board, and fixed with anchor bolt, with glazed hollow bead insulation mortar leveling (20mm thick) coated on the surface of the mortar, the middle laying a layer of mesh cloth. The advantage of this method is that the surface smoothness is good, and the anti cracking effect is good. It can prevent the rainwater from entering and make the rock wool soak.

- Q:How to distinguish warp?and?weft of alkali-resistant fiberglass mesh?

- Warp is the two strands of winding small wire.

- Q:What are the types of glass fiber gridding cloth?

- Specifications for gridding cloth for external walls: 70-160/g. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is used for strengthening cement plaster wall.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords