Manufacturer & Exporter of PVC Foam Board PVC Foam Sheet PVC Foam Panel

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

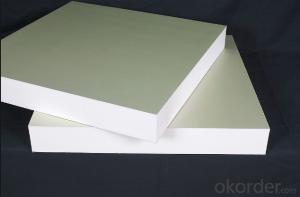

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q:Can plastic sheets be used as barriers?

- Yes, plastic sheets can be used as barriers to separate or block off areas, as they are lightweight, flexible, and can effectively prevent the transmission of dust, dirt, or liquids.

- Q:How do you paint gouache on a plastic board?

- Suggest:1, painted on the plastic plate, spray painted liquid, to prevent premature fall;2, do not direct sunlight, do not store in places where the temperature is too high to prevent falling;3, the best use of oil painting, painting, oil paints of a wide range of applications, can be very good attached to the plastic board, dry should not fall off.

- Q:Plastic type is acrylic. Paper comes off leaving adhesive behind.Have tried: (1) soap and water, (2) Product called Ooops

- Honestly, the adhesive film should just peel up with the paper. Can you gouge the film in an inconspicuous spot to try and get under it to peel it up? Sometimes, depending on how the acrylic is cut, it can be really hard to grab the film.

- Q:Can plastic sheets be used for medical or healthcare purposes?

- Yes, plastic sheets can be used for medical or healthcare purposes. They are commonly utilized in healthcare settings for various applications such as protective barriers, sterilization wraps, wound dressings, and medical equipment covers. Plastic sheets offer advantages such as being lightweight, flexible, easily disposable, and having sufficient barrier properties against contaminants or fluids.

- Q:Are plastic sheets suitable for medical applications?

- Yes, plastic sheets are suitable for medical applications. They are often used in the healthcare industry for various purposes such as surgical drapes, disposable gloves, protective barriers, and medical device components. Plastic sheets offer advantages like flexibility, durability, and resistance to chemicals and moisture, making them suitable for medical settings where hygiene and infection control are crucial.

- Q:What are the environmental impacts of plastic sheets?

- Plastic sheets have significant environmental impacts as they contribute to the depletion of natural resources during their production, emit greenhouse gases, and are non-biodegradable, leading to persistent pollution. They also pose a threat to marine life and ecosystems when they end up in oceans or water bodies. Additionally, the improper disposal of plastic sheets contributes to land and water pollution, harming wildlife and disrupting ecosystems. Overall, the environmental impacts of plastic sheets highlight the urgent need to reduce their usage, promote recycling, and seek sustainable alternatives.

- Q:Are plastic sheets resistant to impact?

- Yes, plastic sheets are generally resistant to impact due to their flexible and durable nature. However, the level of impact resistance can vary depending on the type and thickness of the plastic sheet.

- Q:for our last day of term at uni, we are hoping to make a big water slide down our corridor, (about 12m x 2m) the sheet would have to be waterproof as it will be covered in either washing up liquid or baby oil (probably no actual water) at the minute our cheapest material is looking like bin bags and duct tape, but does anyone know of a cheap, plastic like material we could use instead, to avoid the inevitable leaks from the joins?

- How about going to Home Depot and getting a roll of painters plastic? It is a big roll of cellophane.

- Q:considering using sturdy plastic poster-board or something similar to cover different gaps in the under-body to smooth it out and hopefully improve fuel efficiency. ideas on what to use wanted.I have a small coupe, i am not looking to pay to lower my car. i would like ideas to help me patch up the underbody please. cheap fix to try and save money; very handy and open to strange ideas. all help welcome;please helpful thoughts only thanks

- i hope u rnt seriously considering adding plastic underneath ur car...... 1 word......FIRE HAZARD!!!!! or is that 2 :)..... but yea don't do that now if ur talking about adding a front air dam u gonna need something stronger than poster board..... and btw most modern vehicles come wind tunnel tested from the factory... so u probably wont b improving much anyway.... and even if u do i doubt that u will actually see mpg improvements....

- Q:Extrusion plate fire B1, B2 grade materials, how to distinguish?

- Tight closed cell structure due to continuous extrusion. Its density, water absorption, thermal conductivity and steam permeability are lower than other types of sheet materials, is currently recognized as the best insulation material market.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manufacturer & Exporter of PVC Foam Board PVC Foam Sheet PVC Foam Panel

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords