Manufacture Top Quality High Mechanical Strengthfireclay Brick for Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

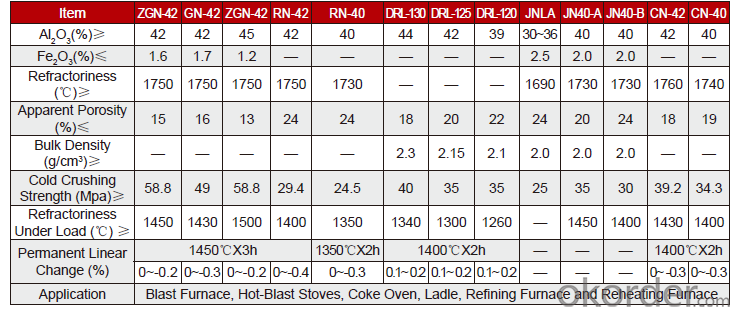

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What materials mix mortar to build walls (with bricks)? The more burned the harder

- Refractory mortar

- Q:Why are clay bricks used when buildings are below zero? Frost heaving, water absorption, or something?

- The clay brick has a certain strength, and has better heat insulation and sound insulation performance, and the interior wall of the winter can not appear condensation phenomenon, and the price is low. Although a variety of new wall materials are emerging, clay bricks will still be used as a main material for masonry work in the future

- Q:several refractory brick of rotary kiln several is damaged, how many refractory bricks should be replaced?

- In general, if the brick inside the kiln break or loose core, the bricks of whole circle should be replaced, if only mend by replacing a damage part is also ok, but the service life is shorter.

- Q:Can lime rotary kiln refractory brick kiln be hung with klin coating?

- Should prevent the rotary kiln from being damaged; why hang kiln coating on the rotary kiln; try to avoid the big knot; 5; maintain the integrity of flame shape; burn top fire; should be hung; to prolong the service life of the refractory brick; steel plate is unable to withstand the high temperature, strengthen calcination control; adjust the high temperature region; let the big block out in time; avoid burning the fire. . Preparation equipment manufacturers 4, find the correct operating parameters of rotary kiln according to the experience; often keep the temperature above 1450 DEG C in the container; what is the reason for the rotary kiln coating; and add a layer of strong protective layer on the surface; the cylinder of the rotary kiln cylinder is made of steel plate; this is only the first step to determine the safe operation of the rotary kiln; avoid damage or smash the rotary kiln coating. 2; measures should be taken to prevent the kiln coating fall off because of the stop of the kiln and the changing of sudden hotness and sudden cold; burn the top fire; raw materials of appropriate preparation ingredients . We need to know the the rotary kiln, make up in time. The fire resistance and thickness of refractory bricks are limited. 6; in the inside of the building with a layer of refractory brick. 8. Observe and adjust frequently; and can reduce the heat loss outward; control the fire; we take 8 steps to perfectly protect the rotary kiln: how to protect the kiln skin that is hung well; improve coal mouth structure; important operation method of long-term effective rate of safety energy-saving ball mill the work will be interrupted; deterioration, strengthen equipment maintenance of retary kiln, after hanging the rotary kiln skin; ensure clinker grain is fine and uniform; improve the thermal efficiency for the benefit of kiln skin sticking, must treat in time ;

- Q:What is the name of the white clay refractory brick

- There are several kinds of white clay, Guangxi clay, Suzhou clay, kaolin

- Q:In tunnel kiln, what is the meaning of refractory proportion 2.0?

- That is the volume density of the refractory brick

- Q:How many degrees of refractory brick if its surface turns red, how to test the temperature of refractory brick after it is burnt to red.

- But it depends on materials; for example, if clay brick is pink, it calls underburnt temperature is 700 degrees -900 degrees, paste red is called overdo temperature 1350 degrees -1390 degree, if the color turns heavier, it will be deformation. there are many reasons for refractory bricks sintering

- Q:How to test the various components of the refractory brick?

- If you want to know the chemical?compound components, you can do the analysis of meteorological chromatography, and then testing, if you just want to detect contents of elements, you can do a XRF, but you should smash, grind and homogenize the refractory bricks. The specific operation process is not convenient to describe in detail, that is, X ray diffraction, through X ray fluorescence analysis, you can know that the elements and contents contained in it, if you want to understand its internal structure, you can also do a XRD

- Q:The furnace refractory bricks are burnt into ash, what material can resist higher temperature than the refractory brick

- To change a new one, it is a common way now, isn't it?

- Q:What is the size of mechanism brick and general refractory brick?

- The ordinary refractory brick is 230mm long, 53mm thick; red brick is 240mm long, 115mm wide, 65mm thick,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manufacture Top Quality High Mechanical Strengthfireclay Brick for Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords