Manufacture Of Rotary Transportation Pump

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10000 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of rotary transportation pump:

Rotary transportation pump is the key equipment for the mechanise production of grc

products, this is a new technique which is referenced from foreign well rounded technique, developed unaided, and suit for the sweeping production of grc. It had used wireless actiyator and grc carriers feeder, it have so many excellences such as feeder continuous, easy handle, high production efficiency, good roduction quality, etc.

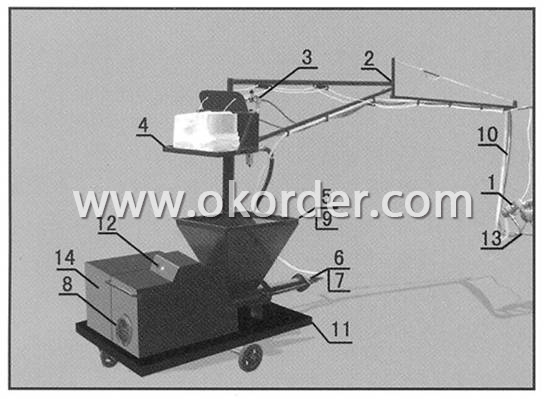

Construction and function of rotary transportation pump:

1. Gunjet: you can select coaxial gunjet or heteraxial gunjet or premixed gunjet or long gunjet as your need.

2. Cantilever: cantilever have two parts, each part is 2 meters, total is 4 meters, so, it can work in a round area, which use eject machine as center and have 4 meters radius. It used for hang the material pipeline and constringented air pipeline, and transfer them to gunjet position.

Working instruction for rotary transportation pump

3. Air element: it contain the air filter and reductor and oil mist element etc. It is used to filtrate the constringented air and adjust the constringented air pressure and lubricate the pneumatic motor.

4. Yarn spindle platform, it can be revolving with cantilever synchronous to avoid yarn twist. Tundish: it is used to reserve material.

5. Spindle: it is a key element with rotor for ls002, their relative movement can export the products continuously.

6.Rotor: it is a key element with spindle for ls002, their relative movement can export the products continuously.

7. Wireless actiyator: this is the power origin, you can adjust the products sendout via it’s rotate speed.

8. Beater: churn the material and send it to the entrance of spindle and rotor.

9. Material pipe: it can make the material transferred from assistant spindle/rotor to gunjet.

10. Pedestal: it is moveable.

11. Control equipment: use this to control the machine.

12. Windpipe: supply constringented air for gunjet.

13. Cover: protect the wireless actiyator

- Q:GRC pouring has been formed, shipped to the scene can be re processed it?

- Almost impossible. The GRC components are all installed first,

- Q:What is a GRC pile composite foundation?

- CFG pile is English Cement Fly-ash Gravel acronym, meaning cement fly ash gravel pile, composed of gravel, stone, sand, fly ash cement mixed with water, the variable strength pile with certain strength made pile with various machinery. CFG pile is a kind of low strength concrete pile. It can make full use of the bearing capacity of the soil between the piles, and transfer the load to the deep foundation. It has better technical performance and economic effect.

- Q:GRC light partition board installation scheme for construction of hydropower pipelines

- GRC lightweight partition board is a new type of wall material developed in recent years. It can eliminate longitudinal cracks as long as it is built according to the order of requirement and new technology of interlocking joint is applied. Therefore, GRC lightweight partition board is one of the ideal materials for building energy conservation and wall reform, and has been widely used in engineering.

- Q:(GRC) substitute material for plates

- Artificial wood made from some wood waste instead of wood fiberThe wood fiber used in some developed countries (wood shavings, etc.) and synthetic resin or inorganic cementitious material composite artificial board manufacture. Our country is lack of timber resources, but it is a large agricultural country, agricultural waste emissions, can be used to replace wood fiber artificial board manufacture, not only can turn and also meet the sustainable development policy. Artificial board basically can be divided into organic binder, artificial board bonded with inorganic binder bonded artificial board two categories.Asbestos cement slabs are replaced by asbestos free fiber cement panels. Many developed countries have recognized asbestos as harmful to human health. Because of its tiny fibers (>3 microns in diameter and <1 microns in diameter), they are carcinogens. Although asbestos cement is still the dominant product of the fiber cement industry all over the world, the varieties of asbestos free fiber cement products are constantly increasing, and the output continues to rise. Some developed countries (such as Sweden, Denmark, Finland, Norway, Germany, France, Switzerland, Holland, Italy, New Zealand, Australia, Singapore) has banned the production and use of all asbestos products; the United States and Canada have stopped in the production of asbestos cement products in China, only allow the import of asbestos cement pipe. According to the development trend of fiber cement products in the world, it is expected that asbestos free cement panels will gradually replace asbestos cement boards as green building materials in twenty-first Century. Our country in this century since 80s has successfully developed a glass fiber reinforced cement (GRC) plate, non asbestos vinylon cement board and non asbestos autoclaved fly ash cement board, which laid the foundation for the further development of such products.

- Q:How to identify new wall panels

- The GRC consists of a steel mold, the vertical mold casting; (2) the new wall is after kneading mechanical equipment, the mixing of the material after forming out of the mold, placed in a relatively flat on the ground, one side flat, side winding; (3) high strength cement wallboard is changed after two kinds of chemical materials after the reaction, the horizontal molding in the mold, each sheet of different thickness.

- Q:What's the difference between partitions?

- Partition board shape is also multi-purpose, the shape is not the same, the functional aspects are not the same, such as well holes, round holes and so on.

- Q:Are there any national standards (strength, protection grade) in the case of GRC materials used as equipment and outdoor rooms?

- Only depending on your equipment, see if there are any special requirements, and then refer to the GRC standard.

- Q:GRC what's the use of imitation wood?

- It can be used as GRC finished generic wood decoration materials used, GRC imitation wood than wood durability, wood decay, and GRC does not use wood is generally 20-30 years Guangyou GRC can be used for 50 years, so the two are not the same.

- Q:How many useful years does the GRC art component have?

- Like the GRC component of the general quality of the normal use is 20 years -30 years, like GRC friends of building decoration component of good quality can be used in 50-80, or the old truth, a penny goods, buy cheap GRC components, service life will be discounted.

- Q:What is the standard of ASTM a283 GRC?

- ASTM a283: American laboratory standard number "a283""Gr c:grade C, this is the steel grade gr (grade) B is B grade steel, equivalent to the domestic Q 235 steel, C is C pole steel, specific equivalent to domestic which kind of steel, check it yourself, I remember not too accurate

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang PORT |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacture Of Rotary Transportation Pump

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10000 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products