Manhole Cover Ductile Iron Square on Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Cast Iron Manhole Cover Description :

Manhole covers are often made out of cast iron, concrete or a combination of the two. This makes them inexpensive, strong, and heavy, usually weighing more than 50 kilograms (110 lb). The weight helps to keep them in place when traffic passes over them, and makes it difficult for unauthorised people not having suitable tools to remove them.

A manhole cover sits on metal base, with a smaller inset rim which fits the cover. The base and cover are sometimes called "castings", because they are usually made by a casting process, typically sand-casting techniques.

2.Main Features of the Ductile Iron Manhole Cover:

•High endurance

•High Strength

•Pressure Resistence

•Anti-corrosion

•Anti-theft

•Good visual effect

Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

Light weight

Compared with cast iron manhole cover, FRP manhole cover is 30% lighter.

Light weight allows more loading per vehicle, more convenient transportation and economical savings.

Allows a safer working condition, which single workers is enough for installation without risk of injury.

Long service life

Strong resistance of acid, alkali, weathering, anti corrosion of water, dust, manhole covers used for gas are well sealed which prevent poisonous gas leaking.

Temperature tolerance is at the range of -40°C-200°

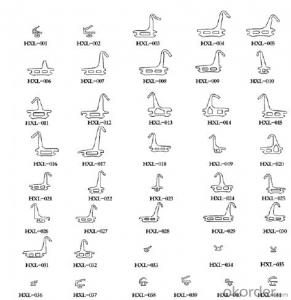

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Material

A) Ductile iron GGG50

B) Grey iron GG20

3) Designs

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

4) Process

A) Molding boards

B) Hand Casting

5) Coating

A) black bitumen or epoxy .

B)Coating as per customer's requirement

6) Different accessories are available

7) Packing:

Wooden case or wood pallet, or as per customers' requirement

8) Payment terms: T/T or L/C

9)Inspection

A)Inspection by our factory

B)The third party inspection,SGS

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. Odours are coming through where I have installed my manhole cover, why?

A. Your cover must be sealed and locked, or neoprene sealed, so you would require a T-Range Cover, or if you require a solid top, a selection of the PC range (e.g. PC2BG3, PC6CG3, not PC2BG) are suitable.

Q. I need access through my manhole cover on a regular basis, is this possible?

A. Yes, the majority of covers have built-in lifting keys, and for those that don’t we also supply lifting keys. However, the best way to obtain easy access is to have a bespoke, hinged manhole cover.

- Q:Nominal diameter 12 washers, outside diameter?

- at present our country flat washer implement related standards are as follows:

- Q:Gasket A140 what is the material

- Gasket A140 is stainless steel, used in corrosive media environment to do flat washers.Gasket introduction:A part between a connector and a nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.Classification:The washer is divided into: -C, flat washer washer -A and grade C, grade -C large washers, washer, flat washer, flat washer, chamfered - - a grade steel structure with high strength washer, spherical washer, taper washers, square taper washers, steel I-beam, square taper washers standard type spring washers, spring washers, light heavy spring washers, lock washers internal teeth serrated lock washers, inner and outer teeth lock washers, serrated lock washers, single ear washers, ears washers, external tab washers, round nuts with washers.

- Q:304 and 201 stainless steel spring washers that soft? Easier to move

- 304 high nickel content, good processing performance! Wayward!201 of the crisp, processing, the processing department will ask you the material, if you want to increase the price of 201!

- Q:Thank you for your support

- If you ask this question if it is to lock up, then want to effect a little better, it is recommended to use double-sided tooth lock washer, I can give you the price of understanding, Baidu my user name!

- Q:In the design, the bolt connection is necessary to have a gasket?

- It is best to add a gasket, there is an increase in friction, it is difficult to prevent aging after the screw.

- Q:Do not use self tapping screws

- No provisions of self tapping screws without gasket, but because the self tapping screws are often used in non regular removal of the place, and will not force big place, so unless there is a need to increase the stress area of the nut, generally do not have to use the gasket.Self tapping screws also have a flat head, in this case, the general should be smaller than the top of the back, or else they can not get into the hole in the ah.

- Q:How to use washer, gasket, o-ring "

- Different purposes, the installation position and the corresponding flange are different, if this is how to choose, advantages and disadvantages, too much information

- Q:Gasket 300HV relative to what material?

- Due to the standard for the 100HV, 140HV flat washers can be made of low carbon steel. General enterprises in the selection of materials, most of the materials used in Baosteel, easy to cold stamping

- Q:When is the gasket (flat pad, spring pad)

- The part between the connecting piece and the nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.

- Q:What's the meaning of the "200HV" of the gasket material? Is that the hardness level? What materials are usually chosen? Know predecessors please advice, younger brother is not very grateful!!!

- Washer / gasket material bar indicates that 200HV is the material mechanical performance grade for steel 200HV.Example: standard series, nominal size d=8mm, performance grade 200HV, without surface treatment of flat washers: washers GB97.1 - 858 200HVA part between a connector and a nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manhole Cover Ductile Iron Square on Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords