Manhole Cover (Cover Only)from China High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

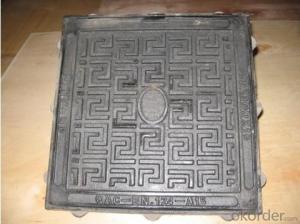

1.Ductile Iron Manhole Cover Description :

1.Advantages: Good compressive, bending and impact strenth,anti-corrosion, not rust, long service life(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

2.Applications: water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

3.Designs: based on EN124 standard and according to customer's drawing or samples.

2.Main Features of the Ductile Iron Manhole Cover:

High load capacity & resilience

Hardness is same as cast iron, while FRP manhole covers have overwhelming advantages on resilience recovery. They are designed to exceed A15/B125/C250/D400 load capacity, according to EN124: 1994.

Designed structure & pressure dispersion

Arc-shaped bottom structure allows the pressure they bear disperse averagely on the whole surface. Besides, the products are made not by SMC, it was put in several layers of fiber cloth to enhance the structures. So they are stronger than SMC composite manhole covers.

Manholes allow access to underground pipes, cables, meters and facilities.

BS EN124 Standard:

A15: Area which can only be used by pedestrians and pedal cyclists.

B125: Footways, pedestrian areas and comparable parks or car parking decks.

C250: For gully tops installed in the area of curbside channels of roads.

D400: Carriage ways of roads(including pedestrian streets), hard shoulder and parking areas, for all types of road vehicles.

E600: Areas of imposing high wheel loads, e.g. dock and aircraft pavements

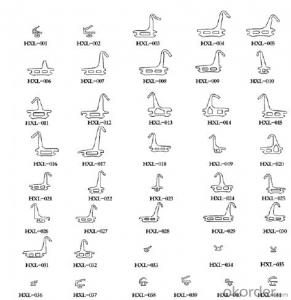

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Material

A) Ductile iron GGG50

B) Grey iron GG20

3) Designs

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

4) Different accessories are available

5) Packing:

Wooden case or wood pallet, or as per customers' requirement

6) Payment terms: T/T or L/C

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. Odours are coming through where I have installed my manhole cover, why?

A. Your cover must be sealed and locked, or neoprene sealed, so you would require a T-Range Cover, or if you require a solid top, a selection of the PC range (e.g. PC2BG3, PC6CG3, not PC2BG) are suitable.

Q. I need access through my manhole cover on a regular basis, is this possible?

A. Yes, the majority of covers have built-in lifting keys, and for those that don’t we also supply lifting keys. However, the best way to obtain easy access is to have a bespoke, hinged manhole cover.

- Q:Flat gasket with what material

- Due to the standard for the 100HV, 140HV flat washers can be made of low carbon steel. General enterprises in the selection of materials, most of the materials used in Baosteel, easy to cold stamping. Here is a brief description of Baosteel standards.

- Q:Why do you have to add a spring washer when it comes to the role of ah ah ah

- If the screw on a spring washer, screw and screw hole fixed, due to the role of the spring washer spring will greatly reduce the possibility of loosening screws, falling off

- Q:What are the advantages and disadvantages of car audio modification, wood washer and plastic washer?

- The plastic washer is made of plastic, plastic washer at home, also known as plastic washers, washers (Washers) resin, plastic washer or nylon washer (the most common domestic market is mostly made of plastic washer nylon 66). Compared with metal gaskets, it has excellent insulation, corrosion resistance, thermal insulation and non magnetic properties, and light weight, widely used in semiconductor, automotive, aerospace industry and interior decoration and other fields. The number of materials used as many as 10 kinds, including PA66, PC, with the best performance of special engineering plastics PEEK, with glass fiber reinforced RENY and PPS, fluorine resin PTFE, PFA and PVD, etc..Wood washer to prevent resonance, but not waterproof.

- Q:Do not use self tapping screws

- Self tapping screws are needed to use the gasket.A part between a connector and a nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.

- Q:Specific conditions for use of spring washers

- A large number of materials in electronic and electrical appliances, carbon, stainless steel, copper alloy etc.. WL type corrugated washer: WL type corrugated washer as a mouth elastic washer, it usually can be installed in a small space, such as to reduce bearing prestress bearing running noise, improve the operation accuracy and stability of bearings. In addition to the electronic appliances also have a large number of applications. Materials are carbon steel, stainless steel, copper alloy, etc.. WN type: WN type wave washers wave washer for multilayer wave overlapping elastic gasket, the series and type WL comparison, because is composed of multilayer material, so in the same compression stroke under the curve of K value is WL gentle, suitable for the whole working stroke and large elastic, elastic and uniform release situation.

- Q:I would like to ask the car transmission inside the thrust washer (thrust washer) is used to do ah?

- Figure 3 thrust washers, 4 needle bearings, thrust washers to prevent excessive wear of the main bearings, the usurper.

- Q:For example, some people ask us to assemble the time zone of the flat washers of the positive and negative side, I would like to ask the installation of flat washers have positive and negative points? If yes, how to distinguish?

- In fact, the reason is very simple, smooth side in the beautiful, no corners in the next, the pressure is small, small damage to the workpiece.

- Q:When is the gasket (flat pad, spring pad)

- A washer to prevent loosening of bolts. That is, elastic washer, anti loose washer works very simple. It consists of two washers. The outside is embossed with a radial surface, while the inner oblique tooth surface. When assembled, the medial oblique tooth surface relative to the outer radial surface and both ends of the contact surface relief into the occlusal state when the connectors are vibration, and the trend of bolts loosening, only allow two washers inside oblique tooth relative dislocation, resulting in uplift of tension, so as to achieve the 100% locking.

- Q:how much Specification for washers

- From 2.5~48, the form of GB/T854-1998, GB/T855-1998, GB/T856-1998

- Q:I would like to ask what is the standard gasket and gasket in general what material?

- Less dosage, the metal with Q235, rubber with XB200, are very common. If the amount is large, according to the situation to choose the most economical

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manhole Cover (Cover Only)from China High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products