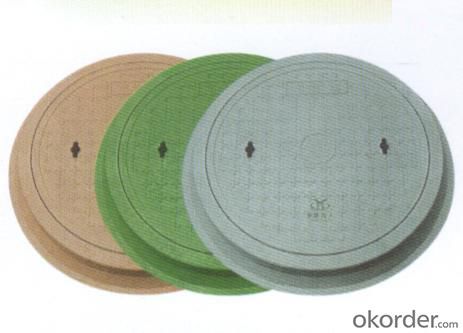

Manhole Cover BSEN 124 Sanitary Sewer Round of SMC Composite Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Ductile Iron Manhole Cover Description :

1.Advantages: Good compressive, bending and impact strenth,anti-corrosion, not rust, long service life(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

2.Applications: water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

3.Designs: based on EN124 standard and according to customer's drawing or samples.

4.Color: black, Grey, green, blue and Marble , etc.

5.Inspection: in-house or the third party as per customer's request.

2.Main Features of the Ductile Iron Manhole Cover:

1. Consequences of temporarily overloading

Temporarily overloading may cause smash of concrete covers, seriously deformation, even slightly split. But this will not happen to FRP fiber cloth manhole cover.

2. Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

3. Light weight

Compared with cast iron manhole cover, FRP manhole cover is 30% lighter.

Light weight allows more loading per vehicle, more convenient transportation and economical savings.

Allows a safer working condition, which single workers is enough for installation without risk of injury.

BS EN124 Standard:

A15: Area which can only be used by pedestrians and pedal cyclists.

B125: Footways, pedestrian areas and comparable parks or car parking decks.

C250: For gully tops installed in the area of curbside channels of roads.

D400: Carriage ways of roads(including pedestrian streets), hard shoulder and parking areas, for all types of road vehicles.

E600: Areas of imposing high wheel loads, e.g. dock and aircraft pavements

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Material

A) Ductile iron GGG50

B) Grey iron GG20

3) Designs

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

4) Process

A) Molding boards

B) Hand Casting

5) Coating

A) black bitumen or epoxy .

B)Coating as per customer's requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

- Q:Install the shaft to install a few gaskets is appropriate?

- As the frame five depending on the length, five links on the left side of the 68mm length of one and two on the right side, the length of the 73mm five on the left side of the right is not installed, install a washer, the thickness is the same as long as you can buy time, usually have three washers.

- Q:What is the reason why the rubber washer is small after use?

- If you do not have any oil around the gasket, which may be used in the process of gasket compression deformation occurred!If there is oil to the present, it is likely that the oil things out of your rubber additives!

- Q:Nominal diameter 12 washers, outside diameter?

- flat washer is usually thin pieces, with different shapes are used to reduce friction, prevent leakage, isolation, to prevent loosening or dispersed pressure.Flat washer is mainly used to decrease the pressure, when some parts of the screw down the axial force is very big, easy to make the pressing dish washer, then can use material and improve the hardness to solve.

- Q:Gasket A140 what is the material

- Gasket A140 is stainless steel, used in corrosive media environment to do flat washers.Gasket introduction:A part between a connector and a nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.Classification:The washer is divided into: -C, flat washer washer -A and grade C, grade -C large washers, washer, flat washer, flat washer, chamfered - - a grade steel structure with high strength washer, spherical washer, taper washers, square taper washers, steel I-beam, square taper washers standard type spring washers, spring washers, light heavy spring washers, lock washers internal teeth serrated lock washers, inner and outer teeth lock washers, serrated lock washers, single ear washers, ears washers, external tab washers, round nuts with washers.

- Q:how to Flat washer installation

- Flat washers are used on both sides, are required to install.

- Q:Specific conditions for use of spring washers

- A large number of materials in electronic and electrical appliances, carbon, stainless steel, copper alloy etc.. WL type corrugated washer: WL type corrugated washer as a mouth elastic washer, it usually can be installed in a small space, such as to reduce bearing prestress bearing running noise, improve the operation accuracy and stability of bearings. In addition to the electronic appliances also have a large number of applications. Materials are carbon steel, stainless steel, copper alloy, etc.. WN type: WN type wave washers wave washer for multilayer wave overlapping elastic gasket, the series and type WL comparison, because is composed of multilayer material, so in the same compression stroke under the curve of K value is WL gentle, suitable for the whole working stroke and large elastic, elastic and uniform release situation.

- Q:How to use washer, gasket, o-ring "

- Spring washer, "casing gasket" and "Liner O-ring", in fact should also be our daily used to seal washer, gasket, O-ring

- Q:When is the gasket (flat pad, spring pad)

- The part between the connecting piece and the nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.

- Q:how to use Motor washer

- What gasket, rubber reduces vibration, metal reduces pressure

- Q:What's the meaning of the "200HV" of the gasket material? Is that the hardness level? What materials are usually chosen? Know predecessors please advice, younger brother is not very grateful!!!

- Should be less than 200HV, which is gasket, should consider the tightness, high hardness of the seal is not good!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manhole Cover BSEN 124 Sanitary Sewer Round of SMC Composite Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords