Magnesite-Zirconia Brick MZ12B

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

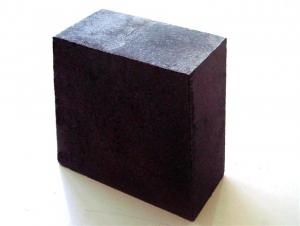

General Information of Magnesite-Zirconia Brick MZ12B

Our magnesite-zirconia brick is a kind of magnesia brick which added ZrO2, it is a kind of alkali resistance refractory brick. Featuring huge volume density, high compressive strength, good thermal stability and strong impact resistance. It can be made into any specification defined by users to fit for different demands. It also has the capacity of maintaining excellent mechanical behavior under high temperature,

Technical Data of Magnesite-Zirconia Brick MZ12B | ||

Physical Properties: |

|

|

Refractoriness | ℃ | - |

Permanent Linear Change(1550℃×2h)% | % | - |

Apparent Porosity, % | % | ≤15 |

Cold Crushing Strength | Mpa | ≥50 |

Refractoriness Under Load (0.2Mpa) | ℃ | ≥1650 |

Thermal Shock Resistance, % | % | 20 |

Density | g/cm3 | 3.10 |

Chemical Analysis: |

|

|

MgO | % | ≥73 |

ZrO2 | % | ≥12.5 |

SiO2 | % | ≤8 |

Note: | ||

Features of Magnesite-Zirconia Brick MZ12B

Low thermal conductivity

Excellent alkali resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Applications of Magnesite-Zirconia Brick MZ12B

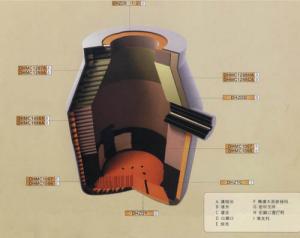

Our Magnesite-Zirconia Bricks are commonly used in glass tank regenerator.

CNBM has success in its refractory bricks due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in refractory brick application and would like to assist you in product selection, system design, and installation techniques. We are looking forward for your inquiry.

- Q:Application of electric high temperature regulating valve?

- Magnesia brick has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and glass industry as well as some high temperature equipment. Magnesia chrome brick more resistant to alkaline slag, and thermal shock stability are much higher than the more widely used, magnesia, magnesia chrome bricks in iron and steel smelting and non-ferrous metal smelting industry has almost replaced the brick, chrome oxide containing (Cr2O3) can be spread, the magnesium chromium brick can easily sticking kiln the skin, so in the past 30 years, has been used with refractory preferred cement kiln, magnesia chrome brick in Cr2O3 water after the reaction of trivalent chromium into six chromium can cause the pollution on the water, facing gradually out of the cement industry market trends. Magnesia and magnesia alumina brick using alumina as raw materials, a magnesia brick compared to thermal shock resistance and high temperature creep performance, use parts and magnesia brick is almost the same. Dolomite brick and magnesia calcium brick performance is almost the same, dolomite brick using dolomite as raw material, calcium magnesium brick with synthetic calcium magnesium sand as raw materials, calcium oxide content in 15-30%, the other is the main component of Magnesium Oxide, with the function of purifying molten steel, usually only used for special steel smelting, the production process of magnesia calcium brick complex water and water steam, easy decomposition, not easy to save transportation, do preventive work must be used in the process of. Magnesia spinel brick is a kind of new products, mainly for the zone and transition zone of cement rotary kiln, will be the main products of the cement industry to replace magnesia chrome brick.

1. Manufacturer Overview |

|

|---|---|

| Location | Liaoning, China |

| Year Established | 2001 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | North America;Eastern Asia;Southeast Asia;Western;Europe;Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 8-15 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 88,000 square meters |

| No. of Production Lines | Above 38 |

| Contract Manufacturing | Construction, installation, maintenance for refractory |

| Product Price Range | High; Average |

Send your message to us

Magnesite-Zirconia Brick MZ12B

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords