Magnesite Refractories Bricks Magnesia Brick for Aod Furnace Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The products are fused magnesia as main raw material, after a reasonable size distribution, high pressure forming, high-temperature sintering. The product has strong resistance to slag corrosion ability and high temperature dimensional stability. Mainly used in glass furnace regenerator, the upper part.

It is a kind of alkaline refractory product with perriclase as main phase magnesia alumina spinel clinker as basic material .The product has such characteristics as good temperature vibration, good strength and volume stability in high temperature.

Application:

1. The regenerative chamber for the ceramic frit kiln, sodium silicate and glass furnace;

2. The furnace lining of iron and steel industry, such as ferroalloys furnace, metal mixer;

3. The non-ferrous metallurgy industrial furnace lining, such as the furnace copper, lead, zinc, tin, etc;

4. The lining for cement rotary kiln;

5. Calcining kiln, shaft kiln and tunnel kiln for refractory material industry

Advantage

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients' quality requirement.

Typical features:

Magnetite bricks, magnetite-alumina bricks and magnetite-zircon bricks etc are the main products of basic refractories. The products have the properties of bearing high temperature, high refractoriness under load and good resistance to alkali. They are widely used in the basic zone of metallurgical furnaces, nonferrous furnaces and regenerator of glass furnaces.

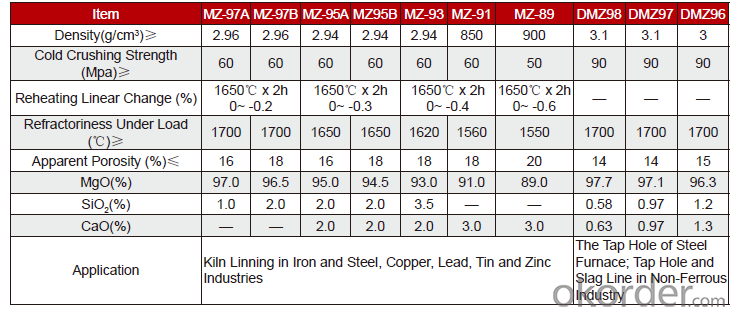

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations

- Q:With different capacitance magnesia brick brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius.

- Q:Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- Manufacture of various refractory magnesia brick Magnesium Oxide, mainly from magnesite.

- Q:How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q:Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

- Q:Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q:High purity magnesia brick masonry mortar for what?

- High purity aluminum is 99.99, the first is not pollution, the stove is high magnesia brick masonry, 95% and 97% purity magnesia brick is for a long time did not find a good bit of fireclay, do not know what to build, now used light burned US powder and heavy burned magnesium plus brine built, with 2 months a griddle doesn't stick on magnesium brick, a touch off, there is no good sintering

- Q:What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- Different grades of burned magnesia brick is mainly made of magnesia binder with different taste, there is not a big difference. However, the physical and chemical properties of binders should be controlled well!

- Q:Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- If you want to know the indicators of chrome brick, magnesia chrome brick must know you are in what furnace above, there is in what position

- Q:How to identify the fused magnesia brick and sintered magnesia brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.Fused magnesia brick brick has compact structure, high mechanical strength, low impurity content, mainly used for the storage of large glass kilnHigh temperature area of the room. The fused magnesia is made of high quality magnesia as raw material. It is made by melting. The English name is fused magnesite. Magnesium hydroxide from magnesite or brucite or from sea water is calcined at high temperature. Strong hydration resistance.

- Q:Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesite Refractories Bricks Magnesia Brick for Aod Furnace Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords