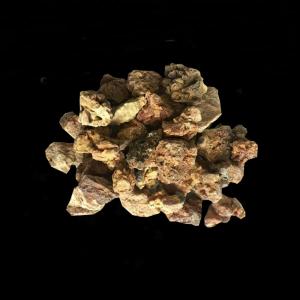

Magnesite Fused Electro-fused Magnesite FM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Liaoning, China

Application: Refractory

Shape: Block

Material: Magnesite

Chemical Composition: Mgo;CaO;SiO2

Mgo:96%-97%

Product name: FM

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: 0-30mm etc

Sample supply: free sample

Color: Brown, white

MOQ: 25Mt

Supply Ability

Supply Ability:1000 Metric Ton/Metric Tons per Month

Grade | MgO | SiO2 | CaO | Fe2O3 | Al2O3 | Loi | B.D g/cm3 |

Dicalcium-fused magnesium | 97.00 | 0.70 | 1.40 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 0.85 | 1.60 | 0.70 | 0.20 | 0.15 | 3.20-3.30 | |

96.00 | 0.95 | 1.90 | 0.80 | 0.23 | 0.12 | 3.20-3.30 | |

Common fused magnesite | 97.20 | 0.80 | 1.10 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 1.20 | 1.30 | 0.70 | 0.20 | 0.10 | 3.20-3.30 | |

96.00 | 1.40 | 1.50 | 0.80 | 0.20 | 0.10 | 3.20-3.30 | |

Size | 0-1mm, 0-30mm, 1-15mm, 1-30mm, 200mesh or according to customer's requirements. | ||||||

Plant photos:

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Port Main port of China

Loading:

What is fused magnesite?

Fused magnesite is produced by high quality magnesite through electro- fusing, After melting, the SiO2 of material moves to the surface for the difference in the specific, so it has well grown crystals, well crystal perfection and structure homogeneity, excellent chemical stability, good corrosion resistance to slag and high strength at high temperature.

Where to apply fused magnesite?

It is widely used for gunning materials, fused magnesite ramming material, magnesite brick, magnesite chrome brick, vacuum and vacuum induction furnace, electric arc furnace refractory lining, magnesia crucible, furnace and a variety of refractory, such as large scale glass furnace by floating method, electrical furnace, convert furnace, house hold electrical appliances as electrical insulating materials,

- Q:What material is refractory material?

- Basic refractory materials, basic refractory, CaO, basic, MgO style alkaline earth oxide. The refractory materials mainly refers to magnesia refractories, dolomitic and lime refractory refractory. Main categories: (1) strongly basic magnesite brick, magnesia carbon brick, limestone and dolomite brick refractory materials;(2) alkalescent magnesia chrome refractories, forsterite refractory, magnalium and magnesia-chrome spinel refractory, basic refractory materials, high-temperature caustic slag, alkaline solvent resistance, strongly acidic slag flux or acidic refractory. The reaction is mainly used in steel furnace such as colour metal smelting furnace and cement kiln.

- Q:What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is a material which has a strong impedance to the heat flow. the nature of the material requires that the material can isolate the delivery of thermal, and the low heat conductivity coefficient and expansion coefficient of the non-metal material.refractory is good in heat resisitance and chamical erosion but not high temperature resistance. Requirements on nature is still in high temperature.

- Q:What are the qualifications of refractory industry?

- 1 business license 2 tax registration certificate 3 organizing institution bar code 4 production permit

- Q:How is grade of fire endurance divided?

- Level of the building is classified according to the importance, fireproofing, durable life and etc. different angles. Civil buildings are classified according to the following ways: 1, It is divided into five grads according to its importance: A, AAA level: Buildings with great memorial, of historic, international and national level. B, A level: High-grade residential buildings and public buildings. C, B level: Intermediate residential buildings and public buildings. D, C class: Ordinary residential buildings and public buildings. 2, It can be classified into four types according to the fireproof performance: Fire resistance level of the buildings is divided into four levels. Standard of fire resistance level is decided based on the combustion performance and fire endurance of the main components of the building. 3, It can be classified into four levels according to the durable life: A, A level durable life is more than 100 years. It is applicable for important buildings and high buildings. B, B level has a endurance for 50 to 100 years and it is applicable for ordinary buildings. A, C level has a durable life of 25 to 50 years. It is applicable for less important buildings. B, D level has a lasting year of below 15 years and it is applicable for temporary buildings.

- Q:Who knows the fire resistant level of the rock wool color plate?

- The rock wool color steel rock wool board is used in a area of high ??fire safety requirements. According to "interior decoration of buildings for fire protection design", the color steel rock wool board belongd to level A. Its life is more than 15 years and still can be used when the temperature is up to about 700 ℃, with maximum fireproofing hour of six hours. And the rock wool color plate is a environmentally friendly material, the preferred material in the construction industry .

- Q:How can refractory material of the electric furnace be used for longer.

- Do not exceed the temperature, do not exceed the limits of use in order to achieve the best performance and the longest service life

- Q:How to divide the fire resistant level of EVB?

- Inorganic materials: Level A incombustible material is mainly divided into three levels, which attributed to two types of materials! Inorganic materials: Rock wool, foam cement, vitrified micro bead, foam glass organic: Eps xps polyurethane phenolic aldehyde, polystyrene particles are divided into two manufacturing techniques including field fabrication and pre-production polyurethane - now sprayed, precast slab eps, xps, phenol - now posted, precast slab (composite board)

- Q:Fire resistance and evaluation of refractory for casting

- The products to be tested are broken and ground, adding organic binders (usually dextrin) that do not affect the refractoriness. Water is used to make standard sized test cones, as shown in figure 1-2-1. Test cone is positive, three edge cone, the bottom side length of 8.5mm, the top side length is 2mm.Test, the equivalent of high standard cone refractoriness of the 2 products to be high, No. 1 and No. 1 high temperature low standard cone of each one, and the 2 to be tested in accordance with regulations frustum cone plug made of high aluminum material, a cone prism and vertical 8 degrees. 1 degrees tilt angle. Then, the cone is heated in a high temperature furnace. When the test cone with a high temperature and bending down to the standard cone top contact cone, the high standard cone refractoriness refractoriness is running.

- Q:What's the classification of refractory material?

- Magnesium aluminum is complex and mainly seeing what classification standard is like according to the appearance shape can be divided into two categories, setting and not setting according to the acid alkali can be divided into acidic, magnesia, high aluminum, ramming expected, spinel, spray coating, plastic, just the quality of the jade, daub material according to the chemical composition is divided into, such as clay, neutral and alkaline according to the operation mode can be divided into different castable, magnesium, calcium, magnesium chrome

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesite Fused Electro-fused Magnesite FM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords