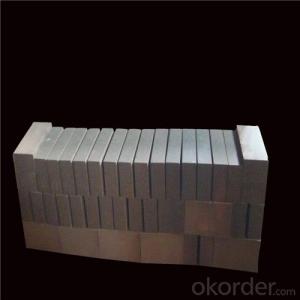

Magnesite-chrome Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesite chrome bricks in magnesium oxide (MgO style) and chromium trioxide (Cr2O3) as main component, and periclase spinel as main mineral components of refractory products.This kind of bricks of high refractoriness, high temperature strength, strong alkaline slag erosion resistance, good thermal stability, also has certain adaptability for acid slag.The main raw material of manufacturing magnesite-chrome brick is sintered magnesite and chromite.Magnesia raw material purity as high as possible, chromite chemical composition requirement is: the Cr2O3:30 ~ 45%, CaO: 1.0 ~ 1.5% or less.

Production technology of calcined magnesite chrome bricks in line with magnesia brick.In order to eliminate the bricks in burning process because of MgO style and Cr2O3, Al2O3, or

Directly combined magnesite chrome brick

Directly combined magnesite chrome brick

Iron oxide reaction caused by the expansion of the spinel as of loose effect, also can use common sintering synthetic materials made from magnesite chrome brick.In addition, there is not burned magnesite chrome brick, for example, combined with inorganic magnesium salt solution is not burned

magnesite chrome brick.Don't burned magnesite chrome brick production technology is simple, low cost, heat stability, but the high temperature strength far less burnt brick.The late '50 s, develop a socalled "direct combination" magnesite chrome brick.The characteristics of this kind of brick is

pure raw materials, sintering temperature is high, the periclase, spinel, such as direct combination between high temperature phase, such as low silicate phase for the island shape distribution, therefore, significantly improve the high temperature strength and slag resistance of the brick.

With chrome ore - magnesia compact grinding calcined after fine powder, and magnesia bricks made of coarse particle with method, is an

effective measure to eliminate the effect of loose.Magnesite chrome brick made of using this method, compared with common magnesia chrome brick, brick of low porosity, compressive strength, high refractoriness under load and the bending strength.With chrome ore - magnesite powder compact, high-temperature synthesis of calcined magnesite chrome magnesia-chrome brick made of sand, slag resistance and high temperature strength are better than other magnesite chrome brick.

In addition, there is electricity solitary furnace molten magnesite chrome material directly casting and fused magnesite chrome brick

(see figure of microstructure, see image), electricity melt magnesium chrome material according to the production of brick melt granule recombination magnesite chrome brick, etc.

- Q:What are the types of magnesia chrome bricks for industrial use?

- It is possible to judge by the concrete kiln. The magnesium chrome bricks produced by real gold company are very good. Our factory purchased them the year before last, and their technicians were very professional, and gave us very good suggestions.

- Q:Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.In addition, magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q:What are the main raw materials of magnesia chrome bricks?

- At present the most widely used are magnesium aluminum alloy, followed by magnesium manganese alloy and magnesium zinc zirconium alloy. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industrial sectors. In practical metals, it is the lightest metal, and the specific gravity of magnesium is about 2/3 of aluminum and 1/4 of iron. It is the lightest metal in practical metals, high strength and high rigidity.

- Q:What is a half combination of magnesia chrome bricks?

- Opacifying particles as periclase spinel crystal structure, fully developed, as part of account of solution structure and matrix.

- Q:How much is magnesium chrome brick a ton?

- Magnesium chrome bricks according to physical and chemical indicators in order to know the specific price, the production of magnesia chrome brick place a lot

- Q:With different capacitance magnesia brick brick

- Fused magnesia brick brick has compact structure, high mechanical strength,

- Q:Magnesia chrome brick

- Magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q:What are the environmental hazards of magnesia chrome refractory bricks?

- Nowadays, the use of magnesia chrome bricks, especially in cement kilns in the construction industry, has been required to be free of chromium, and the cement products shall not be tested with chromium.

- Q:How many kinds of refractory bricks are there?

- Dolomite brick: coating performance, good erosion resistance, but how many bricks f-CaO, yasumizu, it is difficult to transport and storage, production with less.

- Q:What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The magnesia chrome bricks are divided into ordinary magnesia chrome bricks, direct bonding magnesia chrome bricks, half bonded magnesia chromite bricks, fused magnesia chrome bricks, fused magnesia semi bonded magnesia bricks, and unburned magnesia chrome bricks

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesite-chrome Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords