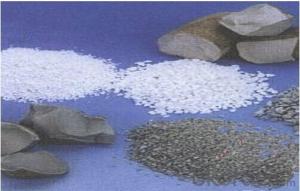

Magnesite Bof Gunning Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Production Technics:

1.Based on high pure magnesia, as the main raw material;

2.adding various compound anchoring agent, ;

3.By mixing and refining.

Production Features:

1.High refractoriness ,excellent resistance for spall , high tap density

2.Easy to spry and sinter, Adhesive rate reach 94% , low rebounding ;

3.Long service life ,once can last 10-24 hours ;

4.Minimum pollutants

Construction method :

1.using quantity:for 30 tons converter, one ton /time

2.Using method : to fill Gunning Mass into the spraying tank (compressed air without water under 2.2-0.4pa ); and then spray to the part need to be repair .

3.After spraying , there will be 20 minutes for sintering ;

4.Note: if somewhere occur weak situation,must stick the brick firstly ,and then spray again .

- Q:What crusher is used for raw material of broken refractory material? What is the rough crushing process? What are the materials? Thank you!

- Common faults and causes of magnetic?separator. 1. Motor of magnetic?separator is overheated and its sound is not normal. Reasons for this failure are: 1) lubrication of bearing is bad or badly worn; 2)fan blade falls off or wears; 3)bad contact of switching circuit or disconnected to run a single phase; 4) voltage is too low. 2. Reasons for this failure due to overheated speed reducer are: 1) lack of oil or poor kerogen; 2) wear between gear and worm, or poor mesh; 3)poor lubrication of bearing or serious wear. 3. The sound of magnetic?separator during operation is abnormal, lattice ball mill. Cylinder is stuck by obstacle, and even the cylinder can not rotate. The bottom box vibrates. Reason for this failure is often that it is stuck by objects in drag flask, otherwise magnetic?patch falls off so that the cylinder screaks and pierce tube when it is serious. At this time, car should be stopped for maintenance and troubleshooting. Only when we master common faults and reasons of magnetic separator can we timely identify problems and solve problems. Better maintenance and repair of magnetic?separator equipment are an important prerequisite to properly use equipment and ensure the construction.

- Q:How much is the content of boron carbide in refractory material?

- furthermore, aluminite powder costs only ?20,000/ton, and the addition is only 0.1%—2%, or just none; while boron carbide costs ?50,000/ton.

- Q:Does hardware construction materials contain refractory?

- refractory includes one kind of building materials. It is a special material and not commonly used.

- Q:Who knows the highest temperature the high-temperature refractory coating can resist?

- The temperature resistance degree of high temperature coating is different according to different coating types. The temperature resistance degree is vary from tens to thousands, magnesia brick: Greater than 2000 degrees dolomite brick: Greater than 2000 degrees casting corundum brick: Greater than 1990 degrees. The above data come from the network, for reference only.

- Q:Who knows the external wall thermal insulation materials fire rating requirements?

- The requirements of Department of Housing and the Ministry of Public Security No. 46: Residential buildings: the height of building is greater than 100 meters, the combustion performance of insulation materials should be level A. The other civil buildings: 24≤ height

- Q:What are the materials used in refractory material processing?

- From the raw material and refractory materials can know, silicides, corundum, clay, diatomite, asbestos, metal oxides, sulfides, carbides and so can be used in the production of refractory material processing, processing of raw materials and refractory material can be used in mechanical equipment, according to production fineness crushing machine, packaging machine equipped with lifting machine, milling machine, so, the complete set of processing production line of refractory raw materials.

- Q:What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

- Q:What are the requirements on fire resistance period of C-level fireproof glass?

- Class C: The fireproof glass which only meets demand of fire integrity. This glass has advantages of transmittance, fireproofing, smoke resistance and high intensity. It can be applied to fireproof glass partition walls, fire windows and with no requirements on outdoor curtain walls, etc. The fireproof glass can be classified as composite fireproof glass and single chip fire-proof glass in terms of structure. Class B: The fireproof glass which meets demands of fire integrity and thermal radiation intensity at the same time. This glass is mostly composite fireproof glass which has advantages of transmittance, fireproofing, and smoke resistance.

- Q:What are the new types of refractories? What are the characteristics? Their applications and developments?

- Special materials often use AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on. Unshaped refractory materials commonly used are fettling, refractory ramming material, refractory castable, refractory plastic material, refractory clay, refractory gunning, refractory cast material, fireproof coating, lightweight castable, mud etc..

- Q:How can refractory materials be divided?

- Refractory materials in China can be roughly divided into refractory products and unshaped refractories.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesite Bof Gunning Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords