Magnesite Aluninum Brick for Copper Making

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

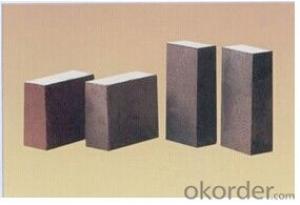

Magnesite Aluninum Brick for Copper Making

Composite of Magnesite Aluninum Brick for Copper Making

Magnesite Carbon Brick is made of various grades of magnesia and is a kind of alkali resistance refractory brick.

Main Features of Magnesite Aluninum Brick for Copper Making

Good high-temperature performance

High thermal shock resistance

Application of Magnesite Aluninum Brick for Alumina Making

Open hearth furnace

Non-ferrous furnace

Glass tank regenerators

Magnesite Aluninum Brick for Copper Making Images

Specification of Magnesite Aluninum Brick for Copper Making

ITEM | M-90 | M-91 | M-92 | M-93 | M-95 | M-96 | M-97 | M-98 |

MgO, % | ≥90 | ≥91 | ≥92 | ≥93 | ≥95 | ≥96 | ≥97 | ≥98 |

CaO, % | ≤3 | ≤3 | ≤2.5 | ≤2 | ≤2 | ≤1.8 | - | - |

SiO2, % | - | - | - | ≤3.5 | ≤2 | ≤2.5 | ≤1.2 | ≤1 |

Apparent Porosity, % | ≤20 | ≤18 | ≤18 | ≤18 | ≤17 | ≤18 | ≤16 | ≤16 |

Cold Crushing Strength, Mpa | ≥50 | ≤55 | ≤55 | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 |

Refractoriness Under Load (T0.6), ℃ | ≥1500 | ≥1520 | ≥1540 | ≥1620 | ≥1650 | ≥1650 | ≥1700 | ≥1700 |

FAQ of Magnesite Aluninum Brick for Copper Making

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

- Q:With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q:Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- The ore quality requirements of MgO = 41%, CaO = 6%, SiO2 = 5%. The resources of magnesite in China are rich. The types of deposits include sedimentary metamorphic deposits, sedimentary hydrothermal metasomatic deposits and weathering leaching deposits.

- Q:How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q:Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q:What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- In addition to the brine binder burned magnesia brick and sulfite pulp waste liquid, Magnesium Sulfate solution binder is generally around 3%

- Q:Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- According to the actual situation, design the brick you need, and the price of brick is determined by the index.

- Q:How to identify the fused magnesia brick and sintered magnesia brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.Fused magnesia brick brick has compact structure, high mechanical strength, low impurity content, mainly used for the storage of large glass kilnHigh temperature area of the room. The fused magnesia is made of high quality magnesia as raw material. It is made by melting. The English name is fused magnesite. Magnesium hydroxide from magnesite or brucite or from sea water is calcined at high temperature. Strong hydration resistance.

- Q:The index of magnesia brick

- indexMGe-20 MGe-16 MGe-12 MMGe-8 DBMK-A DBMK-B DBMK-C MgO≥(%) 40 45 55 60 80 80 80 Cr2O3≤(%) 20 16 12 8 6-8 6-8 6-8 SiO2≤(%) --- --- --- --- 2.0 2.5 3.0

- Q:Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q:Brick price?

- Refractory brick series sintered magnesia brick, magnesia chrome brick, magnesia brick, magnesia spinel brick, magnesia calcium brick, unburned magnesia chrome brick, magnesia brick, magnesia calcium brick, magnesia brick, and al2o3-mgo-c bricks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesite Aluninum Brick for Copper Making

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords