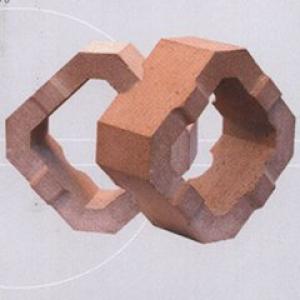

Magnesia zircon brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesium zirconium brick belongs to alkaline refractory products, this product is with high purity fused magnesia and magnesium

synthetic zircon sand as raw material, through high pressure molding, high temperature sintering, the micro structure, the main

mineral phases of periclase forsterite and oblique zircon, the alkali metal oxides and sulfides, has excellent resistance to erosion,

such as magnesium zirconium products are mainly used in glass kiln brick regenerator grid of the upper body, there is no blockage

and collapse phenomenon.Can make the life of more than eight years.

Magnesium zirconium brick chrome oxide as the main component of chrome brick for steel slag erosion resistance, but poor thermal

shock resistance, low load softening degree.The indicators of high alumina bricks are relatively good, has a good cost performance,

so widely used, but because of high alumina brick alkali corrosion resistance is poorer, so cannot be applied to the conditions of use

of the key parts of the complex, silicon mo brick is adopting bauxite and silicon carbide as the main raw material, made of two kinds

of material is mainly used in the transition zone of cement rotary kiln.Carbon refractory carbon bricks, graphite products and silicon

carbide products.Carbon products is another kind of neutral refractory, according to the carbon material composition and mineral

composition of products, divided into carbon bricks, graphite products and silicon carbide products.Carbon brick is made of high

quality petroleum coke as raw material, adhesive and tar, asphalt, under the condition of 1300 ℃ isolate air burning.Graphite

products (except natural graphite) hitches in electric furnace with carbonaceous materials from 2500 ~ 2800 ℃ graphitization

treatment.Silicon carbide products with silicon carbide as raw materials, adding clay, silica and other binder burn into in 1350 ~ 1400 ℃.

Can also add the silicon carbide silicon powder in the furnace under nitrogen atmosphere made of silicon nitride, silicon carbide products.

The carbon products in a very low thermal expansion coefficient of thermal conductivity, high thermal shock performance is good,

high temperature and high strength.Use for a long time also not soften at high temperature, not subject to any acid and alkali erosion,

has the good salt resistance, and wetting of metal and slag, qualitative light, is the excellent high temperature resistant material.

The disadvantage is that oxidation at high temperature, unfavorable use in oxidation atmosphere.Carbon products are widely used in high temperature furnace lining, furnace bottom and hearth, furnace body, etc.), smelting non-ferrous metal furnace lining.Graphite products can be chemical reaction tank and oil autoclave lining.Silicon carbide and graphite products can also be made from smelting copper alloy and light alloy crucible.

- Q:Application of electric high temperature regulating valve?

- Magnesia brick has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and glass industry as well as some high temperature equipment. Magnesia chrome brick more resistant to alkaline slag, and thermal shock stability are much higher than the more widely used, magnesia, magnesia chrome bricks in iron and steel smelting and non-ferrous metal smelting industry has almost replaced the brick, chrome oxide containing (Cr2O3) can be spread, the magnesium chromium brick can easily sticking kiln the skin, so in the past 30 years, has been used with refractory preferred cement kiln, magnesia chrome brick in Cr2O3 water after the reaction of trivalent chromium into six chromium can cause the pollution on the water, facing gradually out of the cement industry market trends. Magnesia and magnesia alumina brick using alumina as raw materials, a magnesia brick compared to thermal shock resistance and high temperature creep performance, use parts and magnesia brick is almost the same. Dolomite brick and magnesia calcium brick performance is almost the same, dolomite brick using dolomite as raw material, calcium magnesium brick with synthetic calcium magnesium sand as raw materials, calcium oxide content in 15-30%, the other is the main component of Magnesium Oxide, with the function of purifying molten steel, usually only used for special steel smelting, the production process of magnesia calcium brick complex water and water steam, easy decomposition, not easy to save transportation, do preventive work must be used in the process of. Magnesia spinel brick is a kind of new products, mainly for the zone and transition zone of cement rotary kiln, will be the main products of the cement industry to replace magnesia chrome brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesia zircon brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products