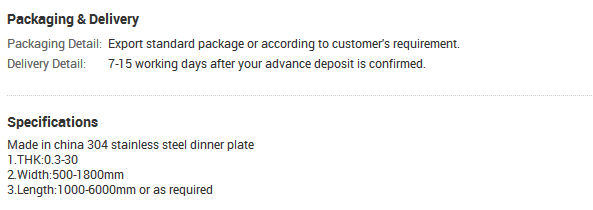

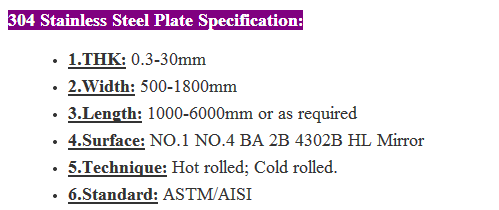

Made in china 304 stainless steel dinner plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Can stainless steel pipes be insulated with polybutylene?

- No, stainless steel pipes cannot be insulated with polybutylene. Polybutylene is a type of plastic material that is commonly used as a water supply pipe. It is not suitable for insulating stainless steel pipes. Stainless steel pipes are already highly resistant to corrosion and do not require additional insulation for thermal purposes. If insulation is needed for stainless steel pipes, other materials such as fiberglass or foam pipe insulation can be used.

- Q:What are the common standards for stainless steel pipes?

- The common standards for stainless steel pipes vary depending on the specific application and industry. However, there are several widely recognized standards that are commonly used in the manufacturing and specification of stainless steel pipes. One of the most widely used standards is ASTM International, which sets the standards for various materials, including stainless steel. ASTM A312/A312M is the standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes. This standard covers a wide range of pipe sizes and grades, including TP304, TP316, TP321, and more. Another commonly referenced standard is the American National Standards Institute (ANSI) standards. ANSI B36.19 specifies the dimensions, tolerances, and materials for stainless steel pipes. This standard covers both seamless and welded stainless steel pipes and includes a range of sizes and schedules. In addition to these standards, there are also specific standards for certain industries. For example, the American Petroleum Institute (API) has standards such as API 5L for line pipes used in the oil and gas industry. These standards outline the requirements for materials, dimensions, and testing for stainless steel pipes used in specific applications. Other standards organizations, such as the International Organization for Standardization (ISO) and the European Committee for Standardization (EN), also provide standards for stainless steel pipes. ISO 1127, for example, specifies the dimensions and tolerances for stainless steel pipes used in general purposes. It is important to note that these standards are continuously updated and revised based on technological advancements and industry needs. Therefore, it is crucial to consult the latest versions of these standards to ensure compliance and quality in the manufacturing and use of stainless steel pipes.

- Q:How do you prevent backflow in stainless steel pipes?

- There are several essential measures that can be taken to prevent backflow in stainless steel pipes. Firstly, the installation of a backflow preventer is crucial. This mechanical device ensures that water flows in only one direction, effectively preventing any backflow. Various types of backflow preventers, such as check valves, double check valves, and reduced pressure zone devices, are available. The selection of the appropriate one depends on the specific system requirements and local codes and regulations. Regular maintenance and inspection of the backflow preventer are also important. It is necessary to ensure that the device is functioning properly and promptly address any signs of wear or damage. Regular maintenance may involve cleaning and replacing worn-out parts to maintain optimal performance. Maintaining proper pressure in the stainless steel pipes is another preventive measure. High pressure can lead to water flowing in the opposite direction, causing backflow. By installing pressure regulators or pressure-reducing valves, the water pressure can be controlled and kept within the recommended range. Incorporating air gaps into the system provides an additional layer of protection against backflow. Air gaps create a physical separation between the water source and the point of use, eliminating any direct connection that could allow backflow to occur. Proper system design is also crucial in preventing backflow. This includes ensuring correct sizing of the stainless steel pipes, appropriate slope, and proper connections. Additionally, locating the backflow preventer in an easily accessible area facilitates regular maintenance and inspection. By implementing these preventive measures, the risk of backflow in stainless steel pipes can be significantly reduced. This promotes the safe and efficient flow of water in the system.

- Q:What is the difference between 310 and 316 stainless steel pipes?

- The chemical composition and intended uses distinguish 310 and 316 stainless steel pipes. 310 stainless steel, with its higher chromium and nickel content, is an alloy highly resistant to oxidation and corrosion in high-temperature settings. It finds suitability in applications like furnace parts, heat exchangers, and other high-temperature industrial processes. In contrast, 316 stainless steel is a more versatile and widely used alloy due to its exceptional corrosion resistance. It contains a higher proportion of molybdenum, enhancing its resistance to pitting and crevice corrosion, particularly in chloride environments. This makes it suitable for applications in marine environments, chemical processing, and food processing industries. To summarize, while both 310 and 316 stainless steel pipes offer corrosion resistance, 310 stainless steel is specifically engineered for high-temperature applications, whereas 316 stainless steel is commonly employed for general corrosion resistance across diverse industries.

- Q:Can stainless steel pipes be used for underground sewage systems?

- Yes, stainless steel pipes can be used for underground sewage systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in underground applications where exposure to moisture and chemicals is common. It can withstand the harsh conditions of sewage systems, including the corrosive nature of wastewater and the pressure from the soil. Additionally, stainless steel pipes have a long lifespan, reducing the need for frequent replacements and maintenance. However, it is important to consider the specific requirements and regulations of the local sewage system and consult with professionals to ensure proper installation and compatibility with other system components.

- Q:What is the difference between duplex and super duplex stainless steel pipes?

- Duplex and super duplex stainless steel pipes are both variations of stainless steel that offer enhanced corrosion resistance and superior strength compared to traditional stainless steel pipes. However, there are some key differences between the two. Duplex stainless steel pipes are made up of a mixture of austenite and ferrite phases, with around equal amounts of each. This balanced composition provides excellent resistance to stress corrosion cracking, pitting, and crevice corrosion. Duplex stainless steel pipes have a higher strength compared to austenitic stainless steels, making them suitable for applications that require higher mechanical strength. On the other hand, super duplex stainless steel pipes have an even higher content of alloying elements such as chromium, molybdenum, and nitrogen. This results in a microstructure with a higher proportion of ferrite phase, further enhancing the material's corrosion resistance and strength. Super duplex stainless steel pipes are particularly resistant to chlorides, making them ideal for applications exposed to aggressive environments such as seawater, chemical processing, and oil and gas industries. In terms of mechanical properties, super duplex stainless steel pipes typically have a higher tensile strength and yield strength compared to duplex stainless steel pipes. This increased strength allows super duplex stainless steel pipes to withstand higher pressures and temperatures. Both duplex and super duplex stainless steel pipes offer excellent corrosion resistance, but the super duplex variant provides superior resistance to a wider range of corrosive environments. However, it is important to note that super duplex stainless steel pipes are more expensive than duplex stainless steel pipes due to their higher alloy content. Ultimately, the choice between duplex and super duplex stainless steel pipes depends on the specific application requirements, such as the severity of the corrosive environment, mechanical strength needed, and budget considerations.

- Q:What is the difference between 2507 and 316 stainless steel pipes?

- The main difference between 2507 and 316 stainless steel pipes is their composition and properties. 2507 stainless steel is a duplex stainless steel alloy that contains higher levels of chromium, molybdenum, and nitrogen compared to 316 stainless steel. This makes 2507 more resistant to corrosion, especially in harsh environments like seawater or chloride-containing solutions. Additionally, 2507 has higher tensile and yield strengths, making it more durable and suitable for applications that require higher strength and resistance to stress cracking. On the other hand, 316 stainless steel is an austenitic stainless steel alloy that offers good corrosion resistance and is widely used in various industries. Overall, the choice between 2507 and 316 stainless steel pipes depends on the specific application requirements and the level of corrosion resistance and strength needed.

- Q:Are stainless steel pipes suitable for food and beverage processing?

- Yes, stainless steel pipes are highly suitable for food and beverage processing. They are corrosion-resistant, easy to clean, and do not leach any harmful substances into the products being processed. Additionally, stainless steel pipes maintain the quality and taste of the food and beverages, making them a popular choice in the industry.

- Q:What is the difference between 2205 and 316 stainless steel pipes?

- The main difference between 2205 and 316 stainless steel pipes lies in their composition and properties. 2205 stainless steel is a duplex stainless steel, meaning it consists of both austenitic and ferritic phases. This makes it highly resistant to corrosion and provides excellent strength and toughness. It has a higher yield strength compared to 316 stainless steel, making it suitable for applications where higher strength is required, such as in the oil and gas industry. On the other hand, 316 stainless steel is an austenitic stainless steel, known for its corrosion resistance and excellent weldability. It contains higher amounts of chromium and nickel, providing better resistance to chloride corrosion and acid attacks, making it commonly used in marine and chemical environments. In summary, 2205 stainless steel is preferred when higher strength and resistance to corrosion and stress corrosion cracking are essential, while 316 stainless steel is chosen for its superior corrosion resistance in chloride-rich environments.

- Q:Can stainless steel pipes be used for oil and gas applications?

- Yes, stainless steel pipes can be used for oil and gas applications. Stainless steel possesses excellent corrosion resistance properties, making it suitable for handling corrosive fluids such as oil and gas. It also has high strength and durability, making it a reliable choice for these applications. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them well-suited for oil and gas transportation and processing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Made in china 304 stainless steel dinner plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords