LZCORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORRIGATED SHEET 7210701000

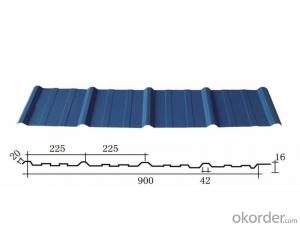

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

In continuous units in cold rolled steel strip, galvanized steel (electro galvanized and hot dip galvanized) as substrate, after surface pretreatment (degreasing and science processing), using the method of roll coating, coated with a layer or multi-layer liquid coating of plate, after baking and cooling income is the coating steel plate. Because the coating can have a variety of colors, on the habits of the coated steel sheet is called color coating steel plate. Because the coating is carried out before the sheet metal forming, in foreign countries which is called pre coating plate.

Color coated steel sheet is an organic coating coating on the steel surface, it has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, easy processing molding, but also allows the user to reduce costs, reduce pollution.

From the United States in 1935 to establish the first continuously coated steel line to begin, color coated steel plate has been widely applied, the current color coated plate varieties, about more than 600 kinds, the advantages of color coated sheet and organic polymer and steel plate of the two, which has good colorability, organic polymer molding, corrosion resistance and decorative, and steel plate with high strength and easy processing, can easily be punching cutting, bending, deep drawing processing. Made this makes organic coated steel sheet products have excellent practical, decorative, workability, durability.

- Q:Are steel sheets suitable for building envelopes or curtain walls?

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel is a strong and durable material that offers excellent structural integrity and can withstand harsh weather conditions. It is also versatile, allowing for various design possibilities. Additionally, steel sheets can be manufactured with different coatings to enhance their resistance to corrosion and provide an aesthetically pleasing finish.

- Q:Are steel sheets suitable for elevator doors?

- Yes, steel sheets are suitable for elevator doors. Steel is a strong and durable material that provides security and safety for elevator systems. It can withstand the constant opening and closing of elevator doors and offers protection against external factors. Additionally, steel sheets can be customized and designed to enhance the aesthetic appeal of elevator entrances.

- Q:Are steel sheets suitable for bridge construction?

- Yes, steel sheets are suitable for bridge construction. Steel is a strong and durable material that can withstand heavy loads and provide structural stability to bridges. It offers various advantages such as high strength-to-weight ratio, flexibility in design, and resistance to corrosion. These qualities make steel sheets an ideal choice for constructing bridges, ensuring their long-term reliability and safety.

- Q:Are steel sheets suitable for automotive chassis?

- Yes, steel sheets are suitable for automotive chassis. Steel is a popular choice for automotive chassis due to its strength, durability, and affordability. It provides excellent structural integrity and can withstand the various forces and stresses experienced by a vehicle during operation. Steel sheets also offer good resistance to impacts, vibrations, and corrosion, making them ideal for use in automotive chassis. Additionally, steel is a readily available material and can be easily formed, welded, and molded into different shapes and sizes, allowing for flexibility in design and manufacturing processes. Overall, steel sheets are a reliable and widely used material in the automotive industry for constructing chassis that meet the required safety, performance, and longevity standards.

- Q:Are steel sheets suitable for kitchen appliances?

- Yes, steel sheets are suitable for kitchen appliances. Steel is a durable and hygienic material that can withstand high temperatures and is resistant to corrosion. It is commonly used in the manufacturing of kitchen appliances such as refrigerators, ovens, and dishwashers due to its strength and easy maintenance.

- Q:Can steel sheets be used for agricultural equipment?

- Yes, steel sheets can be used for agricultural equipment. Steel is a versatile and durable material that is commonly used in the fabrication of various agricultural machinery and equipment. It is known for its strength, rigidity, and resistance to wear and tear, making it suitable for heavy-duty applications in farming and agriculture. Steel sheets can be used to manufacture a wide range of agricultural equipment, such as plows, cultivators, seeders, harvesters, trailers, and storage containers. These equipment require sturdy materials to withstand the demanding conditions of the agricultural environment, including exposure to soil, moisture, and heavy loads. Steel sheets can be formed and manipulated into different shapes and sizes, allowing for the customization of agricultural equipment to meet specific requirements. Additionally, steel can be easily welded, ensuring the structural integrity of the equipment and enabling repairs if necessary. Furthermore, steel sheets can be coated or galvanized to enhance their corrosion resistance, further increasing their longevity and durability in agricultural applications. This helps to protect the equipment from rust and deterioration caused by exposure to various weather conditions and chemicals commonly found in farming activities. Overall, steel sheets are a suitable material for agricultural equipment due to their strength, durability, and versatility. Their use in the manufacturing of agricultural machinery helps to ensure reliable and efficient performance, contributing to the productivity and success of farming operations.

- Q:What is the difference between a perforated and expanded steel sheet?

- A perforated steel sheet is a flat metal sheet with evenly spaced holes, typically created through a mechanical punching process. On the other hand, an expanded steel sheet is formed by cutting and stretching a solid metal sheet, resulting in a grid-like pattern with diamond-shaped openings. While both provide ventilation, drainage, and visibility, perforated sheets offer more precise hole patterns and sizes, making them suitable for applications that require specific hole arrangements. Expanded sheets, on the other hand, provide a more rigid structure, making them ideal for walkways, catwalks, and platforms.

- Q:Can the steel sheets be painted or coated?

- Yes, steel sheets can be painted or coated. Painting or coating steel sheets is a common practice in various industries to enhance the appearance, protect against corrosion, and improve durability. The steel surface should be properly cleaned and prepared before applying any paint or coating to ensure proper adhesion. Different types of paints or coatings can be used depending on the desired finish, environmental conditions, and the specific application. It is important to select the appropriate type of paint or coating that is compatible with the steel substrate and can withstand the intended use and exposure to chemicals, moisture, UV radiation, or other factors that may affect the performance and longevity of the coating.

- Q:Can steel sheets be used for agricultural buildings or barns?

- Agricultural buildings or barns can indeed make use of steel sheets. The utilization of steel sheets for such structures offers a plethora of benefits. To begin with, steel is a robust and enduring material, guaranteeing the longevity of the agricultural building or barn even in the face of various weather conditions and the test of time. Additionally, steel is resistant to pests, such as termites, which often pose significant problems for wooden structures. Moreover, steel sheets possess fire-resistant qualities, thus providing an extra layer of safety. Furthermore, steel sheets allow for a high degree of customization, enabling flexibility in design and construction. They can be easily cut and shaped to suit the specific needs and requirements of the agricultural building or barn. Steel sheets are available in various thicknesses, offering options for different levels of strength and structural integrity. In addition, opting for steel presents an environmentally friendly choice for agricultural buildings or barns. This is due to steel being a recyclable material, meaning that it can be repurposed and reused at the end of its lifespan. This not only reduces waste but also minimizes the environmental impact. Taking all these factors into consideration, it is evident that steel sheets are an excellent option for agricultural buildings or barns, given their durability, resistance to pests, fire resistance, customizability, and environmental friendliness.

- Q:Can the steel sheets be used for metal stamping?

- Indeed, metal stamping can make use of steel sheets. Steel, renowned for its robustness and potency, is frequently employed as a material in metal stamping procedures. Generally, steel sheets are sliced into precise dimensions and shapes before being subjected to the stamping process, wherein a die and punch set are utilized to fashion the desired form onto the steel sheet. This technique enables the production of a diverse array of items, including automotive parts, household appliances, and industrial components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LZCORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords