Luminous Paint,Se-lett,Phosphorescent Paint Hot Selling !!!

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Luminous Paint,Se-lett,Phosphorescent Paint

Luminous Paint (Photoluminescence paint) is a new kind of paint which is glowing in the dark with the function of lighteningThe product is a kind of quick-drying thermoplastic acrylic acid.Easy to operate,with good atomization and sufficient spray.The paint coating is quick drying hard,thick and has an excellent luster adhesion.

2.Main Features of the Luminous Paint,Se-lett,Phosphorescent Paint

• Very fast drying.

• Good adhesion.

•Excellent resistance to water and weathering.

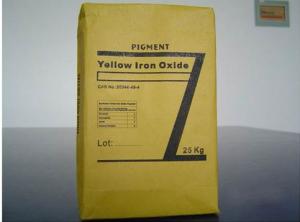

3. Luminous Paint,Se-lett,Phosphorescent Paint Images

4. Luminous Paint,Se-lett,Phosphorescent Paint Specification

TYPE | Antirust paint based on alkyd resins with red oxide pigments. | |

USES | Antirust under coat for steel. | |

CHARACTERISTICS | 1. Very fast drying. 2. Good adhesion. 3. Excellent resistance to water and weathering. 4. Reality low cost. | |

GLOSS | Flat | |

COLOR | Gray | |

WEIGHT | Above 1.3 kg/L | |

VISCOSITY (25 °C) | 90 - 100 KU | |

DRYING TIME (25 °C) | Set-to-touch Dry hard | 0.5 hrs. 2 hrs. |

OPTIMUM FILM THICKNESS | Wet Dry | 90μ(microns) 40μ(microns) |

OVERCOATING INTERVALS (25°C) | Min. 6 hrs. | |

NON-VOLATILE CONTENT | Above 65% | |

THINNER | Toluene | |

THINNING RATE | 70~%(depends on tools used) | |

APPLICATION METHOD | Airless Spray, Brush, Roller. | |

NOTE | 1. Moisture, grease, rust, dirt and loose paints film on substrate must be removed. As a result, paint performance can be ensured. 2. Before application, stir paint evenly. When paint is too thick, thinner can be added within specified quantity 3. Application should avoid the following environment: rainy day; substrate is damp by dew; temperature is above 40°C or below 10°C. 4. Subsequent coat has to wait until paint films of preceding coat completely dry off. | |

5.FAQ of Luminous Paint,Se-lett,Phosphorescent Paint

① The Directions?

1. Remove thoroughly the oil, soil, water stain and dust from the surface to be sprayed.

2. Shake the can well for about half a minute before spraying.

3. Apply first on an invisible part to make sure the selected color is well matched

4. Keep 15-30 cm away from the surface to be sprayed.

5. In case of little paint or only gas out, turn the nozzle 180° and try again.

6. During spraying, keep the can upright within a vertical angle of 45°.

7. After use, clear the valve and nozzle by spraying upside down for a few seconds.

②What's the usage?

Appliance Paint,Boat Paint,Building Coating,Car Paint,Electrical Insulating Varnish,Furniture Paint,machine.

③How about your company?

A world class manufacturer & supplier of castings forging in Spray Paint.This is a manufacturer of tin product,such as aerosol can,food can,beverage can and so on,we began to supply service,and main service is : shaving foam,insecticide,air freshener,super carb cleaner,dash board polish,furnithure polish,polyurethane foam,leather polish,etc.

With advanced machine and perfect insect system,quality of every product are well guaranteed.

- Q:What is a polymer?

- If you are talking about melamine that you see the molecular formula to know, 2, 4, 6-triamino-1,3,5-triazine; if it is through the three polymer is also a ternary polymer. AMPS-AA-MAn ternary polymer

- Q:Production of [time gem] resin Dijiao pigment paste can be replaced with acrylic paint? Or other substitutes

- Oh, the raw materials are different, and glue will be reflected

- Q:Top 10 brands of paint which specific

- From the moment of birth began to countdown, because God wants us to learn to cherish every day, every minute, learn to love each other around the people and life

- Q:Hi is there any websites that show peoples painting skills with just using Microsoft paint? Thanks

- You okorder and search microsoft paint art or something related to microsoft paint.

- Q:Sugar polymer refers to the oligo, polysaccharide it?

- (Starch polymer) cooking starch, mainly mung bean starch, potato starch, wheat starch, water chestnut starch, lotus root starch, starch, starch, starch, starch, starch, starch Starch, corn starch, etc. Starch is insoluble in water, and when heated to about 60 ° C (different types of starch, gelatinization temperature is not the same), paste into a colloidal solution. Grain is the use of this feature of starch.

- Q:DuPont car paint with PPG car paint which is good?

- PPG good point

- Q:How to use the pigment three primary colors (red, yellow, blue) out of brown and brown?

- This should be the amount of the problem with the first three colors mixed with black and then add a lot of yellow and a small amount of red

- Q:I'm painting a bunch of horse jumps on saturday and I already know that I need to sand them and then paint them with outdoor paint, but is there something (clear) I can paint over the outdoor paint to make the paint stay on longer?

- More important than what you put over the paint is what you put under the paint - Primer! Use a high quality primer, with something like KILZ over any knots, and your paint will last a lot longer. Even Marine spar varnish wears out when it gets rain and sun on it. When you're not using them, be sure to store them indoors. I'd also recommend using treated wood for the posts. They rot so quickly. Polyurethane is another good thing to put over the top of your paint. You can get spray on versions that are a lot easier to deal with. Make sure your primer, paint, and sealer are all compatible - some oilbased products do not take well with latex or water based products. Any sealant may change the color of your paint, so test it first.

- Q:Polymer curing process often used DSC, DSC What does it mean

- Differential scanning calorimetry can be used to study the changes in temperature and enthalpy of the polymer during curing.

- Q:How to color leather products

- Squeeze dyeing method The method is to first dye and plastic by dry dyeing method for mixing, and then extruded with a special extruder into a thin, cut into granular. The method of color mixing is good, help to disperse the poor pigment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Luminous Paint,Se-lett,Phosphorescent Paint Hot Selling !!!

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords