Lower Price but Constant Good Quality Polycrystalline 156 Solar Cell High Effciency

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Packaging & Delivery | |

| Packaging Detail: | solar cell, 10boxes*100pcs in one carton, safe enough for transfer |

| Delivery Detail: | 5~7 days after receive deposit |

| Specifications | |

| solar cell for solar panel | |

| 1.16.8%~18.25% high efficiency | |

| 2.100% checked quality | |

| 3.ISO9001/ISO14001/TUV/UL | |

| 4.fast lead time | |

Product Description

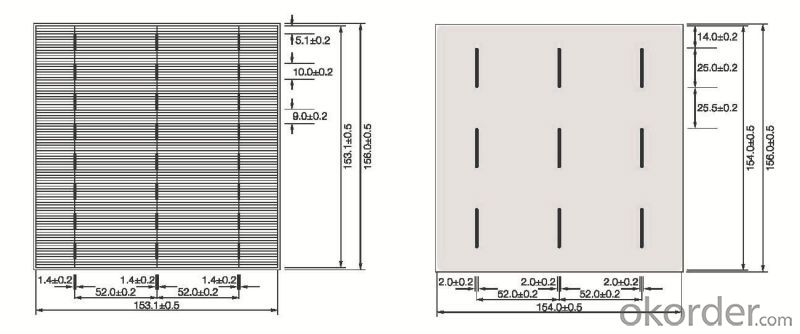

POLY6'(156*156) Multicrystalline Silicon solar celle

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Dimension: 156mm×156mm±0.5mm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm. Distance between bus bars :51mm.

| poly 156 cell Electrical Characteristics( solar cell for solar panel ) | ||||||||||||

| Efficiency(%) | 18 | 17.8 | 17.6 | 17.4 | 17.2 | 16.8 | 16.6 | 16.4 | 16.2 | 16 | 15.8 | 15.6 |

| Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.9 | 3.86 | 3.82 |

| Umpp(V) | 0.53 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

| Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.99 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

| Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.62 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

| Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.22 | 8.151 | 8.083 |

. Warranty:

(1)5years quality assurance resulted from design, material and workmanship;

(2)Not less than 90% power output within 10years;

(3)Not less than 80%power output within 25years;

(4)Third-party insurance(Certificate Of Products Quality Warranty and Certificate Of Products Liability Insurance).

Advantages:

Lower price but constant good quality:

1. Excellent A grade solar cell from JA solar or our own lab;

2. Excellent backsheet from SFC, 3M;

3. EVA from Bridgestone;

4. Junction box with UL and TUV listed, IP65;

5. High transmission low iron tempered glass;

6. Solar panels with TUV, IEC, CE, ISO9001, ISO14001, CEC marked and ETL, MCS in processing;

PACKAGE AND SHIPPING ;

Material in stock can be produce (procedure 5-20days) right away after pre-payment confirmation. COSCO Mearsk MSC or othe ship to worldwide for safe shipping, don't worry about package damager or loss. It take 15-40 days to worldwide, Please note us your contact details include your phone number for easy contacting from shipping company officer.And we have about 12 years in solar panel production and exporting all over th world

Working Principle of Home Solar Cell

Home solar cell is the core part of the solar power system. The role of home solar cell is to convert the sun's light energy into electrical energy, and the DC output is stored in the battery. Home solar cell is the most important part of the solar system, the conversion rate and service life is an important factor in the decision whether to use the solar value.

Brief introduction of Home Solar Cell

1. Cell: High efficiency (over 16.5%) of monocrystalline silicon solar chip package, to ensure adequate power generation solar panels.

2. Glass: low Steel of suede glass (also called white glass), a thickness of 3.2mm, in the wavelength range of the spectral response of the solar cell (320-1100nm) light transmission rate of more than 91%, greater than 1200nm for IR light have a higher reflectivity. This glass also resistant to ultraviolet radiation from the sun, the light transmittance is not decreased.

3. EVA: using plus UV agents, antioxidants and the thickness of the curing agent is 0.78mm high EVA film as a sealant between the solar cell and a glass, TPT linking agent. It has a high light transmittance and resistance to aging.

4. TPT: solar cells on the back cover - fluorine plastic film is white, from the reflection of the sun, so the slight increase in the efficiency of the components, and because of having a high infrared emissivity, can reduce the operating temperature of the component, but also help to improve the efficiency of the module. Of course, this fluorine plastic film solar cell having a first packaging material required aging resistance, corrosion resistance, and the basic requirements, airtight and so on.

5. Border: used in high strength aluminum alloy frame, strong resistance to mechanical shock resistance. Solar Power is the highest value part. Its role is to the sun's radiation is converted to electrical energy stored in batteries or sent to, or promote the work load.

- Q:What is the best way to deal with surplus solar cells abandoned after burning?

- It could be a very good resource to be used, but the technology needs to be more advanced to really deal with that.

- Q:How do solar cells perform in high altitude environments?

- Solar cells perform well in high altitude environments due to several factors. Firstly, at higher altitudes, there is less atmospheric interference, which means that solar cells receive more direct sunlight and can generate more electricity. Additionally, the colder temperatures at high altitudes can improve the efficiency of solar cells, as they operate more efficiently at lower temperatures. Furthermore, in regions with high altitude, there is often less cloud cover and air pollution, allowing solar cells to receive even more sunlight and operate at maximum capacity. Overall, solar cells are highly suitable for high altitude environments and can provide efficient and reliable renewable energy generation.

- Q:How do solar cells perform in extreme temperatures?

- Solar cells generally perform less efficiently in extreme temperatures. High temperatures can cause solar cells to overheat, which can reduce their overall performance. Conversely, extremely cold temperatures can also impact their efficiency. However, solar cell manufacturers often design them to withstand a wide range of temperatures and take measures to minimize the impact of extreme temperatures on their performance.

- Q:Can solar cells be used for water heating applications?

- Yes, solar cells can be used for water heating applications. Solar thermal collectors, which incorporate solar cells, can absorb sunlight and convert it into heat energy, which can be used to heat water for various purposes such as domestic hot water, swimming pools, and space heating.

- Q:Are bulk solar cells better than the normal solar cells?

- Yes, the bulk solar cells are better than normal solar cells because its power supply is bigger than the normal solar cells.

- Q:How do solar cells perform in areas with high levels of volcanic ash?

- Solar cells may not perform optimally in areas with high levels of volcanic ash. The ash particles can accumulate on the surface of the solar cells, blocking sunlight and reducing their efficiency. Regular cleaning and maintenance may be required to ensure the cells continue producing electricity effectively.

- Q:Can solar cells be used for powering universities?

- Yes, solar cells can be used to power universities. Solar energy is a renewable and sustainable source of power that can be harnessed through solar cells. By installing solar panels on university buildings and campuses, universities can generate clean electricity to meet their energy needs, reduce their carbon footprint, and potentially save costs on energy bills. Additionally, solar power systems can be integrated with battery storage technology to ensure a constant power supply, even during periods of low sunlight or at night.

- Q:Do solar cells work at night or in low light conditions?

- Solar cells do not work at night as they require sunlight to generate electricity. In low light conditions, their efficiency decreases significantly, but they can still produce some electricity, although at a much lower rate.

- Q:How much energy can a solar cell generate?

- The amount of energy a solar cell can generate depends on various factors such as its size, efficiency, and the available sunlight. On average, a standard solar cell can generate around 200 to 400 watts of electricity per square meter in optimal conditions. However, technological advancements continue to improve the efficiency of solar cells, allowing for higher energy generation in the future.

- Q:How do solar cells contribute to reducing greenhouse gas emissions?

- Solar cells contribute to reducing greenhouse gas emissions by generating electricity from sunlight, a renewable and clean source of energy. By harnessing solar power, solar cells eliminate the need for conventional fossil fuel-based electricity generation methods, such as burning coal or natural gas, which release large amounts of greenhouse gases into the atmosphere. Therefore, the widespread adoption of solar cells helps decrease our dependence on fossil fuels, mitigates climate change, and contributes to a more sustainable future.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lower Price but Constant Good Quality Polycrystalline 156 Solar Cell High Effciency

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords