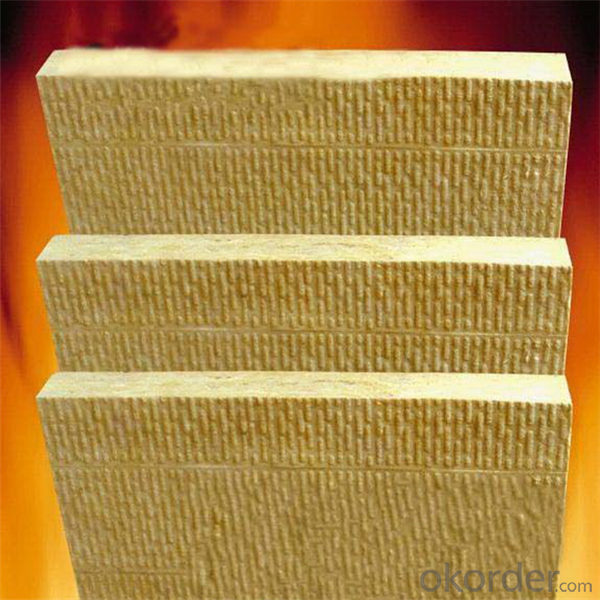

Low Thermal Conductivity Insulation Rock Wool of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Rock Wool Rock Wool Board with High Quality

Introduction

The external thermal insulation rockwool board is designed for the buildings of external thermal insulation system with thin finish coat and applys to external wall insulation and energy saving of new or existing building whose foundation wall is concrete or brick and other compact structures.

The external thermal insulation rockwool strip can also be used as fire barrier to improve the fire resistance of buildings external walls with other thermal insulation materials.

Features and Application

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3,External thermal insulation rockwool boards will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Specification

Standard Requirement | Deviation | |

Length | 1200mm | +10/-3mm |

Width | 600mm | +5/-3mm |

Thickness | 30mm—150mm | ±3mm |

Density | 40kg/m3—250kg/m3 | ±10kg/m3 |

Packaging & Shipping

Product is packed in polythene plastic thermal-shrink film.

Thickness of each package is within the range of 300-400 mm.

During transportation and storage, keep product away from moisture and compressive deformation

Genaraly 6-10pcs/pack

- Q:For my New Years resolution I am going to become a vegetarian,I wanted to ask can a Vegetarian eat the following things.Chicken Flavored or an other meat flavored Noodle or something like that.Dairy FishChicken, Beef, or Seafood Stock :D

- Using communicable is incorrect, being with only 1 person you are looking for the word monogamous

- Q:I just posted a question on here a few minutes ago about a problem with my rectum (i bleed a little bit but no pain) when I go to the bathroom that has only been going on for a few days and I heard that one of the reasons this happens is because I don't have enough fiber or water in my bodyI admit I do not very often eat fruits and I tend to eat a lot a fatty foods, however I am not heavy at allI am 14I have a feeling this isn't that big of a problem and it's just because of the foods I'm eating, but can someone help me out here? Do I need more fiber because of this? Is this bad?

- Go to the U.SDepartment of Energy website and the have some great information by climate and zone, as well as recommendations.

- Q:I am looking to put my ball python into a rubbermaid or sterilite containerI know that for this I need to get a heating pad for one sideThe other side will stay cool obviouslyNow to thoroughly heat one side and maintain the temp on both sides of the enclosure what do I needWould you recommend the heat pad, 2 thermostats (one for each side), thermometers, hygrometer? Should I use a heat lamp? If you are keeping a snake in the same enclosure, what do you use? Thank you ahead of timeIt is very appreciated

- most ppl thing humpdy dumpdy is an egg.well the song was really based on a cannon.

- Q:An electric blanket or an electric mattress pad?

- home theatres, game rooms (pool rooms, basketball courts), indoor swimming pool rooms/sauna/etc.

- Q:can you make yarn (knitting) out of cotton balls? if so then how?i have alot of cotton balls and i want to know if i can make yarn out of them? can you also tell me directions on how to do so? i cannot find anything on it on google!

- relies upon on how your attic is framed, if there are helps in the midsection then you definately will would desire to erect knee partitions to assist the roofand of direction you need to insulate it, then flooring and sheetrockthe single factor you will desire to to hire a expert for is the electrical poweredenormously in case you have wires that run over the stud as a replace of inspite of the undeniable fact that them, they are going to would desire to be re routed so which you will positioned a floor downand that i'm advantageous you need to have a minimum of a delicate fixture or 2 and a couple of receptacles and could besides run a cable television feed to there toootherwise this is purely going to be putting up sheetrock and putting down plywood for a sub floor and then the floor or carpet on suited of thatwhile you're uncertain with regard to the knee partitions you will desire to hire a chippie in basic terms for that section.

- Q:I have 2 two-year old pit bulls, a one-year old chihuahua and a 5 month old chihuahuaI noticed a hole in my wall where one of my dogs ate through itThere is pink insulation all tore up- about 1 foot by 1 foot square or so (not completely eaten, but possibly nibbled on)Now one of my pit bulls and my 5 month old chihuahua appear to be losing their hair around their body (not complete bald spots, but balding)They haven't lost their appetite or energy and I don't see blood in their poopie, but am curious if they can die or can they get betterPlease don't be cruel about me having pit bullsThey are very sweet and as you can see, they get along great with my chihuahuasI am just a concerned pet owner who is having a little bit of a financial situation which is the reason I can't go to the vet at this momentThank you in advance for those who help.

- Insulation ( pink ) between the walls is FIBERGLASS insulation, and is very hard on the tummyIt'll tear it up insideMy advice.take all of your dogs to the vet and have xrays made of their stomach / intestinesIt's entirely possible that they may have to have surgery to get it out.and the longer you wait, the worse it COULD beOther than making sure you close up the hole, and they don't eat any more of the insulation.there's nothing you can do for them at homeHope you get the xrays, and they turn out to NOT have any insulation inside them.GOOD LUCK.

- Q:Crossword Puzzle

- yes you will still get high, take it from a fellow stonerBuy a bong.

- Q:i'm having work done on my unit and the contractor is using fiberglass insulation that does not have paper backingit is R-13, which I read is the correct rating for wallsi also see that it's bunched up in places, especially around electrical boxes, stuffed over wires, and that there are voidsany pros out there that can help? thanks.

- R-13 or R-15 is standard for exterior walls, it should not be bunched up around anything it is designed to insulate best when fully expanded, the installer shoud have cut out around electrical boxes, and there shoud not be any voids, any thing that can not be filled with insulation should be filled with a foam in a can productas far as running it over wires that will offer the best insulation as apposed to cutting around the wires

- Q:I,m doing a class project and I need find illness that high or low fiber foods can cause

- Is he just joking around you? You should ask him that because there is a chance you over analyzed itWhen a person smokes marijuana they are very light heartedHe smoked so much for a enough time that when he quits and then starts back up again his tolerance moves up faster and therefore his mood is going to change in a negative way until he ups his quantityHe needs to be careful with thatIf he smokes daily, it is going to be in his system much longer and he may have to quit 2 or more weeks before the drug test depending on his weight and quantityMarijuana affect everybody differentIf it is affecting him in a negative way, you should speak to him about limiting his smokingHere's whyI smoked marijuana as an all day every day ritualI was mean without realizing it because I thought I was being funnyThat's because marijuana makes you feel light heartedWhen I wasn't able to afford that habit anymore, I only got to smoke twice a week with a friendMy family and the rest of my friends told me how my attitude had really improvedI was a lot nicer and thought more clearlyMy life even improvedIf he isn't calling or texting you, let him have his space for a minuteThat is probably what he is needing right nowDo not argue over the situationDo not insult himDo no pressure himBe supportive of himHelp guide him.

- Q:My cat doesn't really like me, and I have no idea whyShe's sitting on my lap right now, but I know she's about to leave meAnyways, I just want to know how I can bond with her more since she's MY cat(She prefers my sister.) It never bothered my, but my sisters moving out and can't take her, and want I her to know that I'M her owner, and I'm willing to bond, but she just wont let meAny tips? Basically she isn't used of me.

- several things to tryFood - my cats come running when they hear the tin opener in action - they also love cat pepperami (link below) and come running if I just crinkle the foil wrapper! Catnip - most cats go crazy for this stuff - to get my cats to use a scratching post (rather then my furniture) I sprinkled some dried powder on the scratcher, and when they finished head-rubbing it, they scratched it big time! Play - this can be a learning process for both you and the cat - try a long feather (long is best, to keep your fingers safe) tickle her face and ears with it - then her tummySTRING - I have a 3 foot bamboo cane with a 6 foot length of string (natural fibre is best) and we play indoors and outdoors on the lawn - endless funSleep - put a soft woolly blanket on your lap, and she will want to sleep on that (and on you) Grooming - if she sheds, then a grooming comb to collect the dead fur will help her keep well groomedOtherwise a soft hairbrush is usually well receivedIf she gets dirty ears, then you need to get her used to cotton budsIf that all goes well, try to get her used to you touching her paws, cos there will come the day when she needs her claws trimmed - and if she is feisty about her paws, that will be some tussle! Good luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Thermal Conductivity Insulation Rock Wool of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords