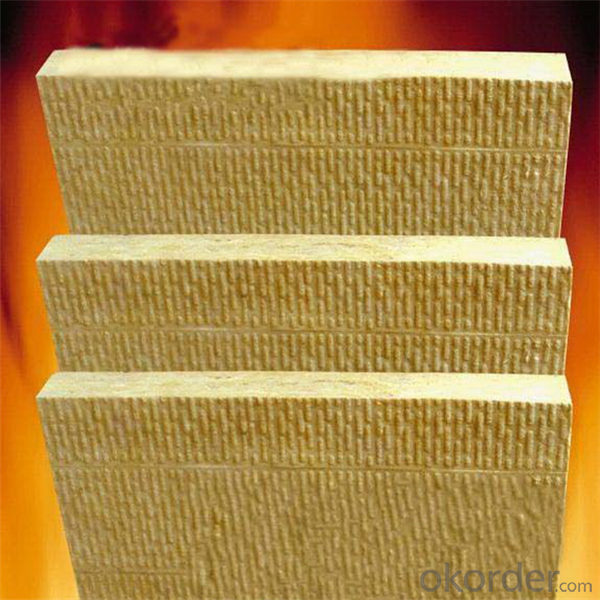

Low Thermal Conductivity Fireproof Insulation Rock Wool of High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Rock Wool Rock Wool Board with High Quality

Introduction

The external thermal insulation rockwool board is designed for the buildings of external thermal insulation system with thin finish coat and applys to external wall insulation and energy saving of new or existing building whose foundation wall is concrete or brick and other compact structures.

The external thermal insulation rockwool strip can also be used as fire barrier to improve the fire resistance of buildings external walls with other thermal insulation materials.

Features and Application

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3,External thermal insulation rockwool boards will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Specification

Standard Requirement | Deviation | |

Length | 1200mm | +10/-3mm |

Width | 600mm | +5/-3mm |

Thickness | 30mm—150mm | ±3mm |

Density | 40kg/m3—250kg/m3 | ±10kg/m3 |

Packaging & Shipping

Product is packed in polythene plastic thermal-shrink film.

Thickness of each package is within the range of 300-400 mm.

During transportation and storage, keep product away from moisture and compressive deformation

Genaraly 6-10pcs/pack

- Q:What's the difference between knitting and crocheting?

- Knitting: uses 2 needles uses less yarn stretchier, drapier fabric generally a better choice for socks, mittens, and sweaters currently more popular, so it may be easier to find an instructor, has more good videos on internet easier to fix a mistake easier to drop stitches generally makes a thinner, smoother fabric (though other textures are possible) only 2 stitches to learn (knit and purl), all the rest come from combinations or manipulations of those two Crochet: uses 1 hook uses more yarn firmer, more highly textured fabric generally a better choice for afghans and doileys easier to get back on the hook after you drop it and the hook falls out requires a smaller selection of tools (hook sizes) generally makes a thicker, more highly textured fabric generally faster by the square yard because the stitches are larger, on average 6 stitches to learn: ch, sl st, sc, hdc, dc, tr (and variations thereof) What they have in common: Both create fabric out of yarn Both are fun Both can easily be done left handed or right handed Both are equally good for making hats and scarves

- Q:Ok i had a huge binge todayi gained 3lbs after eatinglol but its ok i just need to eat something high in fiber to get it all out of my body??? All bran (the cereal) doesn't really work anymore for me for some reason :S Can you suggest anything that will work??? no mean comments I do know im a pigits just emotional eatingthanks

- You need to admit that you need help with this horse from someone else or advise the owner to send him to a more experienced trainerYou may have broken in horses before, but at 17 you are no expert and often we find horses that we are not knowledgable enough to deal with ourselves.

- Q:Hair brush question?

- Take a trip to Boston and go to the top of the Prudential towerfor $12 a person you can go to the top and take great pictures of the view of Boston Lots of great sites to see in Boston and to take pictures off.

- Q:Tell me more about Alexander Graham Bell's work with photomechanical materials?

- Rolling papers (joints Cigars (blunts) bong (water pipe) wood bowl (pipe) metal bowl (pipe) glass bowl (pipe) steamroller one-hitter apple (fruit) hooka Plastic bottles hoses

- Q:I'm going to straighten my hairand i have 2 products , but i don't know which one works better or keeps my hair more healthy?? (besides the fact that straightneing my hair isn't healthy for it) But i don't want to fry all my hair.The 2 products are:Bed Head - Control Freak (frizz control straightener)One 'n Only - Ceramic Silk (thermal protectionironing creme.)Please help! Thank you! :)

- One thing I know for sure with cookies is to never over-mix the doughDo it with a wooden spoon, trust me, the coarser the mixture, the better the outcome, otherwise you'll end up with peanut butter flat cakes.

- Q:When you lose weight, where does it go?

- If it's also a spelling test, you're in troubleMore to the license than you think - Chef instructorLicensed food handler.

- Q:High in fiberI don't want to sound too anal about this, but helpplease?And which are THE best, canned or fresh? And why?Thanks : )

- I am always cold too, so I always wear a beanie (woolly hat that fits the top of your head worn at the back like a scull cap) in winterI even wear it inside the house tooI am in and out of the house all day so a hat really stops that deep bone chillingIf I am really cold, I have a baby's size hot water bottle tucked down inside my coat too before I go outsideTry it, absolute bliss.

- Q:I need to know how cellulose is used in each of the following: clothes, explosives, cell formation, the human digestive system, animal digestive sysem? the most straight forward and uncomplicated answeres would be appreciated, but I would at least need 3 to 4 sentences for each due to the requirements if possible, but anything is highly appreciatedThanks ahead of time!

- I thought anti-Ceiling Cat is a Basement Cat actually he wants to be the only ruler of White House

- Q:I am irregular and feel bloated all the time because of itI evaluated my diet and realized i don't get even close to recommended fiber intakeI eat oatmeal but a small amount and bread with lunch and tht pretty much makes up my fiberThis irks me please help

- check out some sites for the different types, Powder Arts Thermography Warehouse Limited do this sort of stuff

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Thermal Conductivity Fireproof Insulation Rock Wool of High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords