Low Temperature Pressure Vessel Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

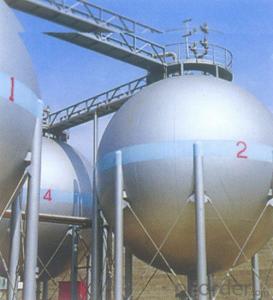

Low temperature pressure vessel (low temperature pressure vessel), is a kind of cryogenic vessel.

Summary

Design of temperature for pressure vessel -20 DEG C; the container is of low temperature pressure vessel for storage and transportation of liquefiedethylene and liquefied natural gas, liquid nitrogen and liquid hydrogen etc..The general pressure vessel commonly used ferritic steels in the temperaturedown to a temperature, the toughness of the steel will decrease sharply, and is very brittle, this temperature is usually referred to as the ductile brittle transition temperature. The use of pressure vessel in below the transition temperature conditions, due to defects, residual stress, stress concentrationand other factors caused by the high local stress such as the existence of a container, the container may be in no obvious plastic deformation under the condition of brittle rupture and disastrous accident. For low temperature pressure vessel must first select suitable materials, these materials should have good toughness at service temperature. The grain size of low alloy steelsavailable to -45 DEG C, 2.5% nickel steel available to -60 DEG C, 3.5% nickel steel available to -104 DEG C, available at -196 deg.c for 9% nickel steel.Below -196 DEG C when the selection of austenitic stainless steel andaluminum alloy etc.. In order to avoid local high stress in low temperaturepressure vessel, in the design of container should avoid excessiveconcentration of stress and additional stress; be strict inspection inmanufacturing the container, in order to prevent dangerous defects exist in the container. For because of the welding residual stress caused by excessive,should eliminate welding residual stress treatment after welding.

Performance characteristics

Cryogenic vessel performance and features of industrial [1] with liquid nitrogenat extremely low temperatures by nitrogen pressure variable is a colorless liquid, low temperature container at liquid nitrogen temperature is very low, and then use the cylinder holding, then put the cylinder in normal temperature, due to the environment temperature, temperature of liquid nitrogen is placed inside the bottle rises, also into the room temperature, then the liquid nitrogen in the bottle pressure will become higher.

But in the actual case, either the cylinder heat preservation effect is very good,or pressure safety valves, cylinders placed either opening time is very short.The cylinder temperature could not reach the normal temperature.

The industrial use of the liquid nitrogen at extremely low temperatures by nitrogen pressure variable is a colorless liquid, then the liquid nitrogentemperature is very low, and then use the cylinder holding, then put the cylinder in normal temperature, low temperature storage tank due to environmental temperature, then:

The bottle containing liquid nitrogen transformation could take place, i.e.vaporized, by liquid nitrogen into gaseous nitrogen, the cylinder pressure rise,this time the inside temperature or liquid nitrogen and nitrogen coexisttemperature is generally -196 degrees, absorb heat temperatures continue to rise, the pressure continues to rise, pressure safety valve will work, relief. If nopressure relief, only temperature, pressure of liquid nitrogen in the cylinder will be very high, resulting in high pressure vessel explosion.

Liquid nitrogen tank insulation effect is very good, the liquid nitrogen can bestored for 1 months does not vaporize finish inside.

- Q:How do steel sheets handle water resistance?

- Due to their inherent properties and protective coatings, steel sheets generally possess excellent water resistance. Steel, being a non-porous material, does not readily allow water to penetrate. The smooth surface of steel sheets effectively prevents water seepage. Moreover, steel sheets are commonly coated with protective layers like galvanized zinc or paint, further enhancing their water resistance. Galvanized steel sheets are furnished with a zinc layer that acts as a moisture barrier and safeguards against corrosion. Zinc displays high resistance to water, and even if the coating sustains scratches, the sacrificial zinc layer shields the underlying steel from rusting. Consequently, galvanized steel sheets exhibit remarkable durability and water resistance, even under extreme conditions. Painted steel sheets represent another prevalent alternative. The paint serves as a safeguarding layer that obstructs direct contact between water and the steel surface. By forming a barrier, the paint effectively prevents moisture from infiltrating the steel and causing corrosion. Nevertheless, it is crucial to acknowledge that the quality and thickness of the paint coating significantly influence the water resistance of painted steel sheets. To summarize, steel sheets possess commendable water resistance due to their non-porous nature and the presence of protective coatings. Whether it is galvanized steel sheets with a zinc coating or painted steel sheets with a protective layer of paint, both choices offer reliable water resistance and prove suitable for diverse applications where exposure to water is a concern.

- Q:How do steel sheets handle electromagnetic interference?

- Due to their inherent electrical conductivity and magnetic permeability, steel sheets are highly effective in handling electromagnetic interference (EMI). These properties enable steel sheets to function as a barrier against electromagnetic waves, preventing their entry or exit from an enclosed space. When exposed to EMI, steel sheets act as a protective shield by reflecting and absorbing electromagnetic waves, minimizing their impact on electronic devices and systems. This shielding effect is particularly vital in sensitive environments like data centers, laboratories, and industrial facilities, where electromagnetic interference can disrupt electronic equipment and compromise functionality. The effectiveness of steel sheets in managing EMI is determined by their thickness and composition. Thicker sheets provide better shielding due to increased attenuation of electromagnetic waves. Certain steel alloys, such as carbon steel or stainless steel, offer enhanced EMI shielding capabilities. It is important to note that while steel sheets offer excellent EMI shielding, they are not completely impervious to electromagnetic waves. Factors such as wave frequency and the presence of openings or gaps in the steel sheet can affect the effectiveness of shielding. Consequently, proper installation and grounding techniques are essential to ensure optimal EMI protection. Overall, steel sheets are a dependable choice for mitigating electromagnetic interference and are preferred in various industries where EMI shielding is crucial for the uninterrupted operation of electronic devices and systems.

- Q:Can steel sheets be used for HVAC systems?

- Yes, steel sheets can be used for HVAC systems. Steel is a common material used in HVAC fabrication due to its durability, strength, and resistance to corrosion. It can be formed into various shapes and sizes to create ductwork, vents, and other components required in HVAC systems.

- Q:Can steel sheets be used for safety barriers or guardrails?

- Yes, steel sheets can be used for safety barriers or guardrails. Steel sheets are often used in the construction industry for their strength, durability, and ability to withstand impact. They can be shaped into various configurations to create safety barriers or guardrails that provide protection and prevent accidents. Steel sheets are commonly used in road safety barriers, highway guardrails, and industrial safety barriers. They are designed to absorb the impact of a collision, redirect the vehicle, and prevent it from crossing into oncoming traffic or hazardous areas. Additionally, steel sheets can be galvanized or coated to enhance their corrosion resistance, making them suitable for outdoor applications where they may be exposed to harsh weather conditions. Overall, steel sheets are a popular choice for safety barriers and guardrails due to their robustness and reliability in providing protection.

- Q:Can steel sheets be formed into complex shapes?

- Various metalworking processes, including bending, rolling, stamping, and laser cutting, enable the formation of complex shapes using steel sheets. By manipulating and transforming the sheets, intricate and custom shapes can be achieved to fulfill specific design requirements. Steel's malleability and strength allow for the creation of complex shapes without compromising its structural integrity. These capabilities find extensive application in industries like automotive, aerospace, construction, and manufacturing, where the demand for precise and intricate components is high.

- Q:What is the process of laminating steel sheets?

- The process of laminating steel sheets involves several steps to create a composite material that is stronger and more durable than traditional steel. First, the steel sheets are cleaned and prepped to remove any impurities or contaminants. This is important to ensure a strong bond between the layers and prevent any defects in the final product. Next, a layer of adhesive is applied to one or both sides of the steel sheets. The adhesive can be a thermosetting resin or a thermoplastic material, depending on the desired properties of the laminated steel. After the adhesive is applied, the steel sheets are stacked together, with the adhesive layer(s) in between. The sheets are then subjected to high temperature and pressure to initiate the bonding process. This can be done using a hydraulic press or a hot rolling mill. The combination of heat and pressure causes the adhesive to melt and flow, creating a strong chemical bond between the steel sheets. The high pressure ensures that the adhesive is evenly distributed and fills any gaps or irregularities between the sheets. Once the bonding process is complete, the laminated steel sheets are cooled and trimmed to the desired size and shape. They can then be further processed, such as by cutting, bending, or welding, to meet specific application requirements. Overall, the process of laminating steel sheets involves cleaning and prepping the sheets, applying adhesive, stacking the sheets, subjecting them to high temperature and pressure, cooling, and finalizing the shape. This process results in a composite material with improved strength, corrosion resistance, and other desirable properties compared to traditional steel.

- Q:What is the difference between a HRPO and HRSPO steel sheet?

- HRPO and HRSPO are both types of steel sheets, but they differ in their manufacturing process and resulting properties. HRPO stands for Hot Rolled Pickled and Oiled, while HRSPO stands for Hot Rolled Skin Passed and Oiled. The HRPO steel sheet is made by subjecting a hot rolled steel coil to a pickling process, which involves removing impurities and scale from the surface using an acid bath. After pickling, the steel sheet is then oiled to prevent corrosion during storage and transportation. This process results in a smooth and clean surface finish. On the other hand, the HRSPO steel sheet undergoes an additional skin pass process after pickling and oiling. During the skin pass process, the steel sheet is passed through a set of rolls to improve the surface finish and reduce its thickness. This process also imparts a certain level of cold work to the steel, enhancing its mechanical properties. In terms of properties, HRPO steel sheets exhibit good formability, weldability, and paintability due to their clean surface and lack of scale. They are commonly used in applications that require a smooth surface finish, such as appliances, automotive parts, and exposed architectural components. HRSPO steel sheets, with their improved surface finish and reduced thickness, offer even better formability and surface quality compared to HRPO sheets. They are often used in more demanding applications where precise dimensional control and surface aesthetics are crucial, such as automotive body panels, electrical enclosures, and furniture manufacturing. In summary, the main difference between HRPO and HRSPO steel sheets lies in the additional skin pass process that HRSPO undergoes, resulting in improved surface finish, reduced thickness, and enhanced mechanical properties. The choice between the two depends on the specific requirements of the application in terms of surface quality, dimensional control, and mechanical performance.

- Q:Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- Carbon steel according to the steel yield strength is divided into 5 grades: Q195, Q215, Q235, Q255 and Q275 of each grade because the quality is divided into A, B, C, D grade, with a maximum of four kinds, some only one; this is just plain carbon steel, the price is cheap, generally not heat treatment. Only quality carbon steel has the value of heat treatment.

- Q:What are the different sheet metal bending techniques for steel sheets?

- There are several sheet metal bending techniques commonly used for steel sheets. These techniques allow for the manipulation and shaping of steel sheets to achieve desired forms and angles. Some of the most common techniques include: 1. V-bending: This technique involves using a V-shaped punch and die set to create a sharp bend in the steel sheet. The material is placed between the punch and die, and force is applied to form the desired angle. V-bending is a versatile technique that can create various angles and shapes. 2. Air bending: In this technique, a punch is used to press the steel sheet into a V-shaped die, but without completely contacting the material. The bending is achieved by controlling the depth of penetration of the punch into the material. Air bending allows for greater flexibility in terms of angle adjustments and requires less force than other techniques. 3. Edge bending: As the name suggests, this technique involves bending the edge of the steel sheet. It is commonly used to create flanges or edges with specific angles. Edge bending is achieved by clamping the sheet between a punch and a die, and applying force to bend the material along the edge. 4. Bottom bending: This technique is used to create larger bends in steel sheets. It involves clamping the sheet between a punch and a V-shaped die, and then applying force to bend the material around the die. Bottom bending is suitable for creating U-shaped parts or boxes. 5. Roll bending: Also known as cylindrical bending, this technique is used to create cylindrical or curved shapes in steel sheets. The sheet is passed through a set of rolls, which gradually bend the material into the desired shape. Roll bending is commonly used in the production of pipes, tubes, and cylinders. 6. Coining: Coining is a precision bending technique that creates crisp, sharp bends. It involves pressing the steel sheet between a punch and a die, with the die featuring a sharp edge. The material is subjected to high pressure, resulting in a precise and defined bend. These are just a few of the many sheet metal bending techniques available for steel sheets. Each technique has its advantages and applications, and the choice of technique depends on factors such as the desired angle, the thickness of the sheet, and the complexity of the shape being formed.

- Q:Are steel sheets suitable for medical equipment manufacturing?

- Yes, steel sheets are suitable for medical equipment manufacturing. Steel is a versatile and durable material that is commonly used in the production of medical equipment. It offers several advantages such as high strength, corrosion resistance, and ease of customization. Steel sheets can be easily formed, welded, and machined to create complex shapes and structures required for medical equipment. Additionally, steel is a hygienic material that can be easily cleaned and sterilized, making it suitable for use in healthcare settings. Overall, steel sheets are a reliable choice for manufacturing medical equipment due to their strength, durability, and ease of fabrication.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Temperature Pressure Vessel Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords