Low Smoke Halogen Free Flame Retardant Polyolefin Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LSZH compound:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

LSZH compound:

1. Applications and cable specifications of LSZH compound:

Common jacket for flame retardant wires and cables which operation temperature is at 90 degree C.

2. Description of LSZH compound:

Thermoplastic, low-smoke, halogen-free and flame retardant POE jacket compound, based on POE resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of LSZH compound:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature degree C | 140 | 145 | 150 | 150 | 145 | 145 |

Note:Compound should be dried at 70-80 degree C before use, which has been stored more than two months.

4. Storage and transport of LSZH compound:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of LSZH compound:

| Item | Unit | DW9021 | DW9023 | DW9023B | DW9023C | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.48 | -- | 1.5 | -- | 1.5 |

| Hardness | Shore A | -- | 95 | -- | 95 | -- | 95 | -- | 96 |

| Tensile Strength | ≥MPa | 9 | 12.5 | 9 | 12.5 | 9 | 12 | 9 | 10.5 |

| Elongation at Break | ≥ % | 125 | 200 | 125 | 190 | 125 | 230 | 125 | 150 |

| Thermal Aging | degree C * h | 110×240 | 110×240 | 110×240 | 110×240 | ||||

| TS/EB Retention | ≥ % | 75/75 | 105/86 | 75/75 | 110/82 | 75/75 | 104/91 | 75/75 | 115/85 |

| Hot Deformation 80 degree C 4(6)h | ≤ % | 50 | 22 | 50 | 21 | 50 | 24 | 50 | 16 |

| Impact Brittleness Temperature | ≤degree C | -20 | pass | -20 | pass | -20 | pass | -20 | pass |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1011 | 1.1×1012 | 1.0×1011 | 2.3×1012 | 1.0×1011 | 1.8×1012 | 1.0×1011 | 2.9×1012 |

| Oxygen Index | ≥ | 33 | 33 | 35 | 36 | 37 | 38 | 38 | 40 |

| Smoke Density Flaming | ≤ | 100 | 66 | 100 | 62 | 100 | 51 | 100 | 54 |

| Non flaming | ≤ | 200 | 135 | 200 | 132 | 200 | 143 | 200 | 125 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.3 | 4.3 | 5.7 | 4.3 | 6.1 | 4.3 | 6.1 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 1 | 10 | 1 | 10 | 1 | 10 | 1 |

| Content of halogen acids | ≤ mg/g | 5 | 1 | 5 | 1 | 5 | 0.9 | 5 | 0.8 |

| Toxicity Index | ≤ | 2.5 | 1.2 | 2.5 | 1.1 | 2.5 | 1.7 | 2.5 | 1 |

| Thermal Impact Test Condition 150 degree C*1h | No cracking | Pass | No cracking | Pass | No cracking | Pass | No cracking | Pass | |

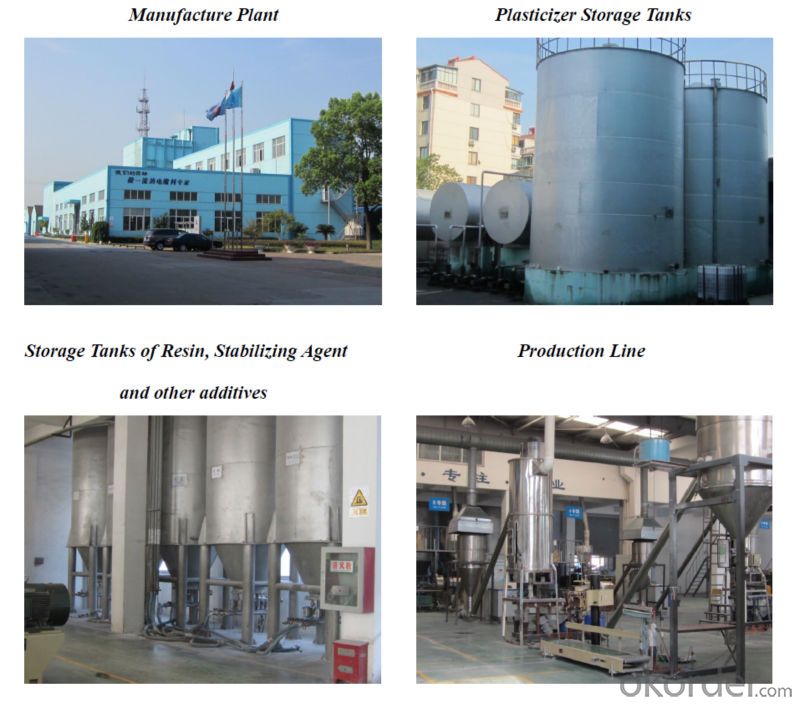

6. Company

- Q:Is the plastic with high melting index good?

- Its test method is: first let the plastic particles in a certain time (10 minutes), under certain temperature and pressure, melt into plastic fluid, and then through a diameter of 2.1mm tube g (grams) outflow. The greater the value, the better the processability of the plastic material, the worse the contrast.

- Q:What is plastic material E-PET?

- With the prevalence of the hardware industry, more industry technology is dazzling, and the technology that we know may not be even longer, so here we are talking about what is the real PET plastic.Polybutylene terephthalate mainly consists of polyethylene terephthalate two (PET) and polybutylene terephthalate (two) (PBT).PET is highly symmetrical and has certain crystalline orientation ability, so it has high film forming ability and plasticity. PET has good optical properties and weather resistance, and amorphous PET has good optical transparency. In addition, PET has excellent wear resistance, friction and dimensional stability, and electrical insulation. PET bottles are widely used because of their high strength, good transparency, non-toxic, impermeable, light quality and high production efficiency. PBT and PET molecular chain structure similar, most of the same nature, but the main chain from two methylene into four, so the molecules are more supple, processing performance is better.

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- In general, the lenses of PC need to be covered with scratch resistant protective films, which will be sufficient for better aging, and most lenses for children.

- Q:What material do you need for plastic film? Do you use this material?

- Plastic bags, quality, food grade requirements, the use of brand new HDPE (low pressure polyethylene).

- Q:What are the raw materials of plastics made of?

- Some plastics are pure resins, such as polyethylene, polystyrene and so on. They are called single component plastics. Some plastics, in addition to synthetic resins, also contain other auxiliary materials, such as plasticizers, stabilizers, colorants, various fillers, etc., known as "multi component plastic.".

- Q:What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

- Q:Dissolve in 0.3 of the LDPE plastic raw materials what?

- Low density polyethylene (Low density polyethylene, referred to as LDPE) is usually based on ethylene monomer in high pressure 98 ~ 294MPa, with oxygen or organic peroxide as initiator, the polymerization of the polymer, the density of 0.910 ~ 0. 9259/cm3. medium density polyethylene (MDPE) density is 0.926 ~ 0.9409/cm3; very low density polyethylene (VLDPE) density below 0.910g/cm3.

- Q:What are the main biodegradable plastic bags made of?

- Biodegradable plastics(1) natural polymer modification method. Starch, cellulose, chitin, lignin, seaweed and other natural polymers as raw materials, through chemical modification and copolymerization method, these molecules were modified to synthesize biodegradable plastics.(2) chemical synthesis. The simulation of natural polymer structure, starting from simple water molecules, in the polymer chain of plastic with active groups such as amide, peptidyl, ester compounds containing these radicals, similar to natural protein structure, fragments of grease, easily biodegradable.(3) microbial fermentation, many microorganisms can take some organic substances as carbon source, through metabolism, secrete, produce polyester polymer, these molecules are easy to degrade, and can be further recycled.

- Q:Can PE material be used as food grade plastic?

- Yes, of course, but the raw material suppliers have already divided the ingredients into food grade, and they will be used in non food occasions to contain substances harmful to the bodyFor human health, please choose food grade PE materials, and note that the highest temperature can not exceed the manufacturer's maximum limit, otherwise the material will appear unstable, resulting in harmful substances

- Q:What are the raw materials for plastic products? Resin or oil?

- Plastic is a kind of macromolecule organic material with resin as its main component. It can form a definite shape at a certain temperature and pressure and maintain a definite shape at normal temperature.Usually refers to the resin conversion or melting range when heated into force with mobility, at room temperature is organic polymer solid or semi-solid or liquid plastic, it is the most basic and most important components. Broadly speaking, in the plastics industry, any polymer used as a basic material for plastics can be called resins.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Smoke Halogen Free Flame Retardant Polyolefin Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords