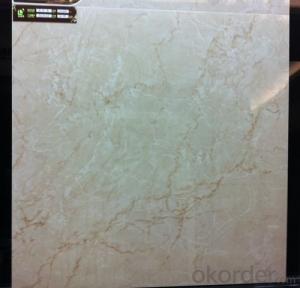

Low Price + Polished Porcelain Tile + High Quality 8R10

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information of Polished Porcelain Tile CILO26608:

1.Size:60x60/80x80cm tile

2.Certificate:CE ISO

3.W.A. <0.5%

4.Material:Porcelain

Features of Polished Porcelain Tile CILO26608:

1. Size:600*600mm;800*800mm Porcelain tile

2.Various colors are available;Fashion and elegant pattern tile

3. Usage: use in Inner Floor.

4. Engobe(water proof)

5. Certificate:CE;ISO;SONCAP

6.Tile Minimum order: 1x20'FCL (items we have in stock can be mix loading)

7.Delivery Time : within 25 days after received 30% payment by TT

8.Payment term: L/C; T/T, 30% deposit, balance paid before loading.

9.Packing: standard carton with wooden pallet or per customers' request

- Q:I recently bought a house, second-hand, would like to renovate, floor tiles do not know demolition is not demolished, would like to ask, it is best to have friends in Guangdong Foshan, the following questions, answer well, and real, The best information can refer to, must be given! My home on the 7th floor, stairs roof Demolition of tiles to find someone to split the floor? Has not been found to really remove the floor of the price, in the end package clean up is how much a square, I want the price of Foshan Do you want to tear down the house with a broken machine?

- Package to the decoration together to do the matter, is it in Chengdu? Chengdu we can build

- Q:the one where i can picture of single tile not the whole floor

- Google American Olean, Florida tile, Dal Tile, Mohawk, Laufen, U S Ceramics, Crossville,Armstrong,Congoleum, or Interceramic. These are a few major manufactures of tile. Most show individual tiles as well as some whole floors. Any questions you can e mail me through my avatar. GL

- Q:What are the tiles?

- 1, polished turn: the type of brick with clay and stone powder pressed by the press, and then fired from the front and the opposite color, not on the glaze, burned, the surface and then polished, so positive It is very smooth, very beautiful, the back is the original face of the brick. Polished we all know? Such as stone floor and wall, is polished, stone province is not bright, but polished, it looks very bright. Since it is polished, the problem will follow, because the smooth, bright, so it is not dirty, and dragged with a mop, will leave the water mark, because your mop can not be 100% Clean it, like the same glass, so if you want to clean, it is more effort; The second drawback is that polished because of smooth, so it is not slip, that is, once the water on the ground, it is very slippery, which is why we see the building inside the stairs and other shops are not the stone Cast into light, but matt, the only way to non-slip. The third problem is the color of the liquid is easy to penetrate, the simplest test is to take the pen in the brick surface to write a few words, poor polishing turn, immediately wipe after writing, are not necessarily able to clean, writing may have infiltrated Well, good brand, because the press is good, high density, coupled with the firing of the high temperature, the density is very high, so it is not easy to infiltrate, but this is not absolute, no matter how good the polishing, if write the word 10 Minutes and then rub, but also must leave the traces of never wipe, because the ink has been infiltrated into the brick inside.

- Q:Bai Peng tiles origin? how is it?

- You have not provided the brand we have tested, to provide you with the method of selecting the tile, I hope to help you. 1 election origin Almost tiles on the market come from two places: Guangdong and Shandong. Guangdong brick overall quality is better than Shandong brick, domestic brands of ceramic tile origin is also generally from Guangdong, so a simple choice of Guangdong brick. (Shandong bricks are also good quality, but more need to blink of an eye). 2 to see flatness Flatness is very critical, if the flatness is very poor, it is difficult to shop in the edge of each tile are not the edge of the gap, there is not only the impact of visual effects affected, serious and even cause Ge (gè) feet. Figure tiles flatness is very poor gap is too large Method one: the same paragraph of the two tiles on the face of the table, his hands pinching side, observe the other side of the tilt, tilt the smaller, the higher the flatness. (This method is suitable for fully flattened bricks that do not apply to antique tiles and bricks with special craftsmanship)

- Q:What kind of ceramic tile?

- Features: This is a kind of high temperature firing ceramic tile, is the hardest of all the tiles. Sometimes polished tiles are scratched when the tiles are still safe and sound. Mosaic: Mosaic is a special way of the existence of brick, it is generally composed of dozens of small pieces of brick to form a relatively large brick. Acid, alkali, wear, no water, strong pressure, not broken. Categories It is mainly divided into ceramic mosaic, marble mosaic, glass mosaic. Scope It is small and colorful, colorful is widely used in indoor small area, wall and outdoor walls and the ground. Features Specifications, thin and small, hard texture, acid, alkali, wear, no water, strong pressure, not broken, colorful and versatile.

- Q:I laid a new porcelain tile floor in my bathroom. Old linoleum tile floor was in good shape so I just laid right over the top of it. All turned out well except around the toilet. Two of the tile cracked when I screwed the toilet back down to the floor. Obviously I‘ll have to pull the toilet again, remove cracked tiles and start over....but how to I avoid the cracks again?

- The fact that those tiles cracked tells you that they were not supported from below. Your linoleum must be not well anchored there. You could try to cut out the linoleum and build up extra thin-set there to achieve the same height as the rest of the floor OR you could anchor the linoleum with extra glue where it was not supported before replacing your tiles. Personally, I prefer the first solution.

- Q:Ready to buy tiles, no conditions to buy the brand, and we look at a British brand, I would like to ask these two models about how much the sale price? LC-8823 and ZC-8001

- Tell the landlord do not like to listen to, you said the brand I was in the tile industry for so long, I basically have not heard. The The The The It may be my personal ignorant it, Oh ~ ~ ~ ~ ~ ~ general you said the brand 800 * 800 market price (if the business is not black heart) probably: 25-40 between each piece, if beyond this price You buy it then. The The The The The Oh, if higher than the price of the proposed landlord to see: the new Pearl Group's brand, Mona Lisa, Hongyu, Enuo, the king, strong and other brands, are more reliable products in the end of the product.Or I answer those friends of those words: In fact, what brand is not important, it is important that you do not understand the tiles, teach some of the industry to identify tiles good or bad way, hope to help you:

- Q:I almost bought porcelin tile but I know ceramic tile is much more popular, what about the endurance factor between the two? I want to get something that will last and still look good.Does anyone know about flooring, and could tell me which is best?

- Porcelain is a more dense tile with less water absorption. I prefer porcelain over ceramic. In most cases when/if you get a chip in porcelain it is much more noticeable. In any case, your taste will most likely determine your choice. However, tile has ratings, i.e., 1 thru 5. 1 being less durable and 5 being most durable. 1's and 2's would be a wall tile and 3-5 would be a floor tile. Ask your supplier when you see something you like. If he doesn't know, go somewhere else.

- Q:hi we have old carpet on top of tiled floor in our dining room the carpet really needs replacing but I have no idea how to fix the grippers down onto the tilesany ideas how I can do this without pulling up the tiles?

- buy a foam backed carpet and then use a spray adhesive to stick the carpet edges down.

- Q:Jiyuan where the tiles are good

- 1, look at the back of the swivel to see if the color is pure, generally pure color display for the milky white (partial white), can not be black, can not be yellow, the surface is not black, black hair to prove that the brick itself has impurities, Impurities more than the density of brick is more down, usually in the course of practical problems prone to fracture, damage. But the back of the brick body can not be very white that is not normal, indicating that zirconium silicate raw materials used too much, the national test tiles have no radioactive one of which is the detection of zirconium silicate raw materials practical amount of zirconium silicate raw materials can make brick Whitening, but zirconium silicate is also one of the main killers of radioactive, be sure to pay attention. General manufacturers have a national test report certificate, you ask them to produce it, note: must be booked with the kind of color certificate book or product brochure behind the parameters that is not a copy of the inspection report, that thing is Can be forged.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Price + Polished Porcelain Tile + High Quality 8R10

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products