Low price concertina spiral cheap razor barbed wire mesh fence

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 8000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The blade gill nets, also known as snake belly mesh gill nets or scraper type: a new safety net, a recent years, protection, isolation ability of new products.

It uses a steel stamping molding package attached to the top of the wire (stringlessness), blade sharp sharp corners galvanized steel or stainless steel sheet, high-tension wires that core line is a combination of denial equipment.

Sharp knife stabbed into a bellows-like two-buckle installed after both beautiful people not Haner Millet. Played a very good hole scare.

The product has a beautiful, economical and practical, to discourage effective, convenient construction excellent characteristics, a long time, the world blade gill nets have been widely used in military areas, prisons, detention centers, government offices, banks, and the living area walls, private walls windows and doors of homes, villas, highway, railway fence, border line to protective security, obviously has become the mainstream of the High fences.

Material: high quality and low in carbon steel with stainless steel band

Process: Chong rolling

Features: excellent protective performance, beautiful, great variety, rapid construction, the deterrent effect

Usage: military border, prisons, defense agencies and facilities, important state facilities, residential, residential barrier protection.

The blade gill nets roughly divided into spiral, straight, spiral cross three forms.

- Q:Is it possible to protect the radiation around the computer with a wire mesh?

- I have not heard of the wire, the chassis cover is the original radiation ah. Just do not advocate bare metal battle (no chassis or 24 hours cover)

- Q:Construction in the wall and the beam at the junction of nail wire mesh what role

- Acceleration of heat dissipation, because the thermal conductivity of iron is relatively strong, so the ground heat evenly.

- Q:How does proe draw wire mesh?

- The main is the rest assured that the grid generation, first in accordance with the form of a grid to draw a curve, of course,

- Q:How the wire is welded

- Wire, the most suitable for resistance spot welding. Resistance welding, welding without welding wire gas and other consumable materials.

- Q:What is the use of wire

- If the rust does not remove, this sponge-like rust is particularly easy to absorb moisture, iron is rotten faster

- Q:Wall tiles how to hang iron wire mesh

- Cold galvanizing process: cold galvanized is degreased, rusted, showing a dirty, penetrating welded wire mesh, hanging in the cathode of the special plating tank, galvanized anode. Connected to the DC power supply, the anode of the zinc ions migrate to the cathode and discharge on the cathode, so that the welding wire coated with a layer of zinc layer method;

- Q:This material of the barbed wire in the water I do not know how long?

- Fenqiang barbed wire is cold galvanized welded wire mesh, is the choice of high-quality low-carbon steel wire welded wire welded wire mesh, advanced welding process in each intersection are vertical and horizontal welding,

- Q:What is the barbed wire fence? What is the general specification?

- The appropriate bending, creating a unique aesthetic effect of this product, and the surface can be used in a variety of colors of the dipping treatment, columns and mesh with different colors is pleasing to the eye, while the use of such products with a chassis

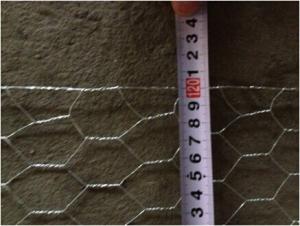

- Q:Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The sparseness of the network is different, in general, the larger the mesh, the closer the mesh is. The smaller the mesh, the thinner the cell.

- Q:What is the effect of the wire mesh on the floor

- Fixed pipe: the surface of the insulation layer of steel mesh with nylon cable ties to fix the pipe, characterized by faster construction, positioning accuracy, the overall effect of pipe installation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low price concertina spiral cheap razor barbed wire mesh fence

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 8000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords