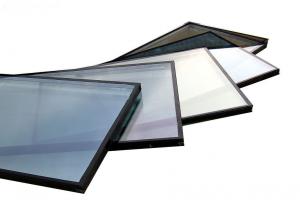

Low-e Insulating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Glass is made up of two or more pieces of glass which are separated by metal frames, its edge is sealed with the glue by way of jointing and welding.

Features of Low-e Insulating Glass:

1. Heat preservation and energy conservation

2. Anti-frost and anti-dewing

3. Sound insulation

4. The aluminum bar is bent automatically. Automatic molecular-sieve filling system, vertical coupling and vertical automatic sealing can guarantee the production of high-quality insulating glass technically.

5. Compared with common insulating glass, the sealing is reliable for homogenous coating with no bulbs between the layers.

6. good appearance, good dew point

Specifications of Low-e Insulating Glass:

Thickness: 2-19mm

Size:

2500*5000mm(Max)

250*300mm(Min)

Applications of Low-e Insulating Glass:

Insulating Glass is mainly used as building glass in curtain wall, glass doors and windows, etc.

- Q:Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- Ordinary glass float line cooling is a long process, the glass also has compressive stress, but the compressive stress is small, uneven distribution

- Q:What are the raw materials for making glass?

- Sandstone fused glass has a bright luster, and has a good transparency, acid resistance and mechanical strength.

- Q:How do you make the glass, please? What is the raw material?

- If there is, use calcium carbonate, silica, and sodium carbonate in a platinum crucible or clay crucible or corundum (alumina) crucible and melt to obtain glass.

- Q:What are the chemicals in glass?

- Common raw materials are quartz sand, feldspar, calcite, calcium carbonate, three, two aluminum oxide, sodium carbonate, borax and so on.

- Q:What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- Zircon is mainly an igneous rock formed from magma crystallized zirconium, silicon and oxygen composition of minerals. Zircon is also produced in the dikes and metamorphic rocks. It belongs to the tetragonal system, and is often a well developed cone shaped small tetragonal cylinder, but also irregularly granular. Crisp, broken shell like. It's high quality refractory. With Jin Hongshi, ilmenite, monazite and xenotime in beach sand, and the water, electricity, magnetic separation and other beneficiation process.

- Q:Cement / glass raw materials, equipment, principle, composition, characteristics, uses and types

- This is a useful feature because it prevents edges from becoming rounded, loss of tooth shape, and disappearance of surface imprinting, which is conducive to a vivid appearance. Kaolin hydrated aluminum silicate (Al2O3 2SiO2 2H2O), plays the role of adhesive to improve the forming ability of non sintered ceramic. Because of its opacity, the content is minimal. Although many repair ceramics contain free crystalline phases of quartz, they should be described as glass; rather, high melting ceramics can be called feldspathic glass". In the production of medium and low melting ceramics, the manufacturers mix various ingredients to melt them and then quench them in water. Quenching causes internal stresses, causing large cracks and fractures throughout the glass. This process is called the heating of glass material, and the product is called glass material. The brittle structure thus formed can easily be ground into powder for use by the porcelain artist. During the pre melting of ceramics, thermochemical reactions occur between the components, and the shrinkage associated with this reaction occurs. In subsequent chamber sintering, powders are fused together to form restorations. The melting temperature depends on the composition of the glass and must be carefully controlled to minimize thermoplastic flow. Potash (potash) and sodium (soda) is a carbonate or natural minerals (such as feldspar) to be introduced in the form of.

- Q:Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q:Failure reasons and solutions of insulating glass.

- To keep the sealant unchanged for a long time, it must require the sealant has good anti-aging properties, if the material quality is not good, it will affect the life of hollow glass products, in all sealants, most can reflect is butyl rubber as the basic raw materials of various types of sealant sealant and moisture barrier properties, and so on standard hollow glass curtain wall curtain wall must adopt double sealing is a very correct decision. Here are a variety of sealants water vapor permeability coefficient table, from the table we can see that the structure of glue can not be used as insulating glass sealant alone.

- Q:What kind of glass is smoked glass?

- FluxThe melting point of silicon dioxide is very high, in order to achieve this Rongdian is very limited. The ancients had to add some other substances when it becomes low melting temperature. When silica melts down also very obtrusive in the process of heating without gradually filtering transition soft, into some other the material of the glass can be in different temperature range all the splendor, powerful shaping operation and effective setting. This substance is a flux.

- Q:How do you pack something into (Qian Jin) plexiglass?

- The organic glass is divided into two layers to seal the flat object and then polish it.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | Southeast Asia; Mid-East; Africa |

| Company Certifications | CE;RoHS;ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Low-e Insulating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords