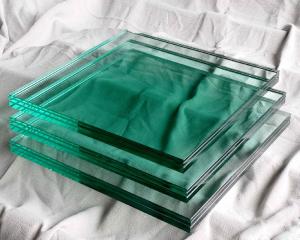

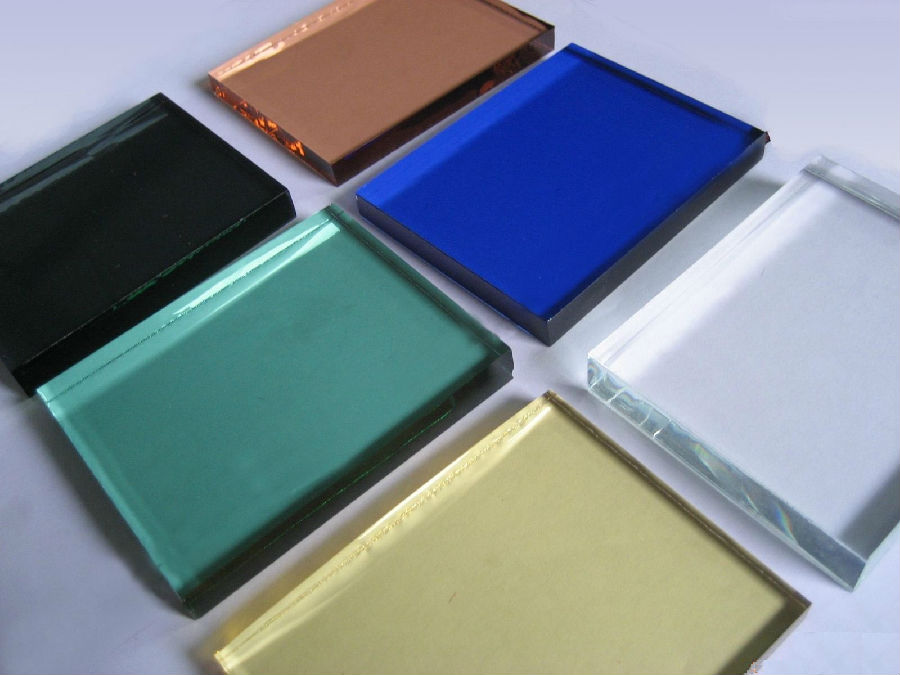

LOW-E Glass Sheet with 3-8mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LOW-E Glass Sheet with 3-8mm

Thickness:3-8mm

Size:3300x1900mm 3300x2134mm

3300x2440mm 3660x2250mm

3660x2134mm 3300x2250mm

660x1900mm 660x2550mm

Feature:

1.Low-e glass is glazed with an ultra-thin metallic coating. The manufacturing process

applies this with either a hard coat or soft coat process.

2.This glass is an energy efficient way to control the heat being allowed in and out of

a home or environment.

3.Low-e glass allows visible light to pass through it but blocks heat-generating ultravio-

let light, requiring less artificial heating or cooling to keep a room at the desired temp-

erature.

4.The coating used to make low-e glass works to transmit short wave energy,allowing

light in, while reflecting long wave energy to keep heat in the desired location.

5.Low-e glass comes in high, moderate and low gain panels. In especially cold climnates,

heat is preserved and reflected back into a house to keep it warm. This is accomplished

with high solar gain panels.In especially hot climates, low solar gain panels work to

reject excess heat by reflecting it back outside the space.

6.Soft coated low-e glass is more delicate and easily damaged so it is used in insulated

windows where it can be in between two other pieces of glass.

7.Hard coated versions are more durable and can be used in single paned window.They

can be used in retrofit projects.

Application:

Low-E insulating glass unit

building facades

Window

Interior glass screen

- Q:Sorry if this is a really stupid question, please go easy on me.Tell me if this is possible or not:An aviary that in 10m or more long in length which houses smaller species of birds. Part of the aviary is against the house and a window. The window is tinted so that the birds don't think that they can fly through it (but would the reflection still be a problem?). But people in the room can see through the window and the birds in the aviary.Possible or bad idea? Any alternatives? I have seen entire aviaries made out of acrylic and see-through, and also a restaurant with a massive aviary the size of the wall behind glass, I just wonder how they do it without birds breaking their necks on the glass.

- why would an aviary have glass if its abig aviary like a small shed try making one out of flat tin and paint it pretty so it looks cool then make a door out of stuff like chicken wire and shade cloth.(material thats tightly bound so nothing can get out) or if its just two birds just get a large metal cagey thingy

- Q:How much would it cost to build a 15 foot glass wall that is 1 inch thick and 8 feet in heigh

- I suggest you contact your local glass merchant. I am not being rude but you need more than dimensions to give you an answer. 1, First where do you live. The price in New York is likely to be different than the price in Juneau, Alaska (or in Chiang Mai Thailand where I live!) 2. Do you need a single piece of glass or a lot of smaller panes 3. What specifications for any joints? 4. Do you want the price of construction included or will you do it yourself? 5. Do you want the materials delivered or will you pick them up. 6. What about cost of transport / shipment? I hope you understand what I am getting at. There are too many factors for anyone on here to be able to help you. Therefore contact a local glass dealer and give him/her your EXACT requiremernts and they will give you the only meaningful answer that you will get.

- Q:I am looking to build an aquarium, I figured if I do it myself I could save lots of money. I am looking to build about a 200 gallon. At pet stores I have seen aquariums approx. this size and they would sell for around $900. I have called local glass companies and gotten quotes for 3/8 thick tempered glass and just the glass is about $1000 dollars. Does anyone have suggestions or knowledge of building custom aquariums, where I could build my own for a fraction of the cost to buy a new one?

- Float Glass Vs Tempered Glass

- Q:I want to build a small soundproof glass room in my living room, since i have another family member moving in and it will be hard to talk over the phone at night and listen to music, since I already share my room. I picture it as big as a phone booth but just longer some how so I can lay in it and just talk on the phone or use my laptop. I have no idea what company I should search for to build a glass soundproof room that small. or maybe it can be about 10 feet by 5 feet. No matter if its sliding door or not. Any info would help me. Thanks Even personal stories on other kinds of soundproofing that works thats affordable.

- Hi, breathing might be a problem for you in your glass sound proof room! How long can you hold your breath for? You might consider a super large fish tank for your glass room purposes, whether not not you add water and fish (for some company) is up to you. Personally, I would just go and sit in the car or lock yourself in the bathroom!

- Q:I am making a stained glass panel with a lighthouse in it and I want to put windows and doors in the lighthouse. Do I cut them out somehow or put something over the glass

- First the negative bits:- An outdoor wedding would save lighting but risks bad weather and also some guests may not be able to hear well if there is any wind. The set-up costs of this also have to be taken into account and may well be more expensive and create more vehicle emissions than a church or hall wedding venue. Transport is the main emitter of un-green pollution which is under the control of individuals, followed by un-necessary lighting (e.g. upward facing floodlights that mainly light the bottom of clouds). For example: It's very sweet to have a wedding on a tropical beach or a Carribean island; but the CO2 emissions (as well as the cost) of getting everyone there is obscene. If you have to shuttle the wedding party between venues then hiring a bus would be ok. It would also make parking easier at the reception - but where would the guests leave their cars at the wedding venue? Would they be safe? Also, what about those who want to leave at different times? There's always some who don't want (or can't) wait around to the end of the festivities. Now the positive bits:- It would be a Green decision if you had the sites adjacent or in easy walking distance of each other. It's not everyone's cup of tea, but to go green why not have the wedding in a venue local to where the majority of the guests live. You could try asking the bridesmaids to use second-hand dresses instead of having specially made gowns. This isn't as mean as it seems - it's eliminating waste on the production and materials for clothes that would otherwise only be worn once ( the bride's dress is the natural exception). Best of all to go Green would be not to fly anywhere for your honeymoon. If you're travelling beyond a hundred miles then go by train (the greenest of all transport except for a bicycle). Try spending your wedding night in a railway sleeper compartment. That could actually be extremely romantic (James Bond always makes it seem so) and the train crew will make a big fuss of you.

- Q:Do you know about the glass substrate production process?

- Is the original film production process? The production process is simple.

- Q:Brother concerned about the glass film for a long time, always wanted to engage in, I do not know how the prospects, please enlighten me predecessors! Thank you, brother first!

- With the state for the introduction of energy-saving policies and local governments for building energy-saving provisions, combined with the current building doors and windows tend to penetrate the development direction of energy consumption to reach about 50% of the entire building. The market appears on the coated glass is basically to block the strong dazzling light, do not have insulation, cold, isolated UV explosion protection and other functions. Currently on the market is the best double-filled inert gas (nitrogen) his effect is better than the film effect, but the price is high. Sum of these aspects of the glass film market prospects you should have a few, right? But now speaking, the film market is still in the promotion stage, the market has not really opened. Investment should be cautious.

- Q:Is there really a decelerating glass?

- exist. Deceleration glass is actually a laminated glass, is made of two layers of tempered glass in the middle of a layer of PVB film made of such glass damaged by external forces, the glass fragments are still sticking to the film, and will not fly out to the car crew Causing secondary damage. High-quality slowdown glass has good optical properties, good light transmission, no light distortion, etc., can be very real reaction outside the scene shape and running state, the vision is very clear, with no glass visual effects, plus sandwich technology But also has a certain degree of insulation, soft light effect, make people feel more comfortable. In fact, the correctness of the glass used on the means of transport (including cars, trains, airplanes, etc.) is: safety glass.

- Q:Korea architectural glass film brand

- Now a lot of Korean film is actually domestic to do, but South Korea's raw materials, the specific brand about to know

- Q:Worried about the bathroom glass will blew, paste the security film can be resolved?

- Generally can not burst, if you worry about the ordinary transparent tape can be posted, and very useful. Safety film and the role of ordinary tape is not much difference.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LOW-E Glass Sheet with 3-8mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products