Low carbon steel expanded metal mesh (manufacturer )

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

expanded metal panel

1.expanded metal concept: expanded metal, also called tensile net, punching shear nets, diamond metal, perforated plate, heavy expaned metal sheet...

expanded metal sheet is the sheet metal after punching shear with punching shear machine , tensile and become with diamond mesh of sheet material network products.

Special designs or size is also available at customers' request!

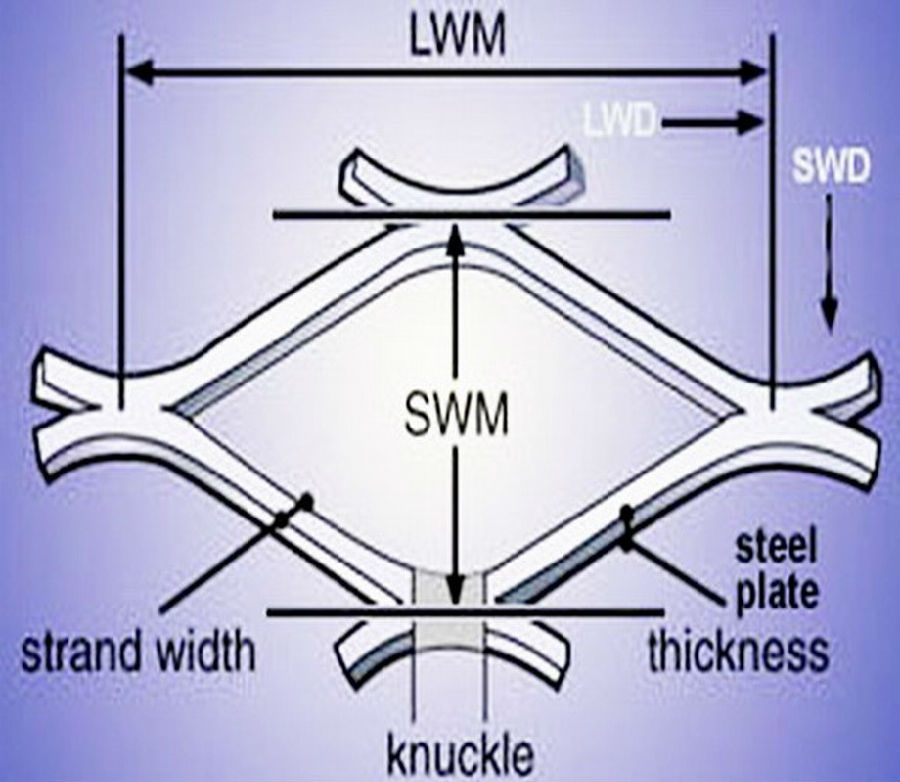

The diagramming of the expanded mesh sheet. We can make the 3m width and 10mm plate thickness expanded mesh.

SWD- short way diamond

LWD- long way diamond

BOND- where two strands intersect

STRAND WIDTH- length of the metal used to produce one strand

STRAND THICKNESS- guage thickness

LWM (WIDTH)- mesh sheet size, the distance of lwd direction

SWM(LENGTH)- mesh sheet size, the distance of swd direction

2.Material: We can supply expanded mesh in a variety of materials including aluminum, platinum, brass, steel, low carbon steel,copper, nickel plates,

stainless steel, and is usually purchased from steel mills in Tianjin.

3.Packing: The packing usually is pallet or wooden box to avoid damage or deformation to the aluminum product.

Of course, we can packaging according to your requirement.

4.Application: Used with concrete in buildings and construction, maintenance of equipments, making of arts and crafts, covering screen for first class sound case. Also fencing for super highway, studio, highway. Heavy expanded metal can be used as step mesh of oil tanks, working platform, corridor and walking road for heavy model equipment,

boiler, petroleum and mine well, automobile vehicles, big ships. Also serve as reinforcing bar in construction, railway and bridges. widely used in the core of filter, medicine, filtering, breeding, battery, mechanical protecting, making the crafts, the meshes for the high-grade sound box, decoration, the seating for children, baskets, etc.

- Q:Is steel wire mesh suitable for use in automotive filters?

- Indeed, steel wire mesh proves to be a fitting option for application in automotive filters. Renowned for its robustness, potency, and ability to resist corrosion, steel wire mesh emerges as an impeccable substance for automotive filters. It adeptly sieves out particles and detritus from the air or fluids that traverse through the filter, thus guaranteeing the engine's optimum performance and longevity. Moreover, steel wire mesh proves impervious to elevated temperatures and pressure, rendering it a suitable choice for automotive filters that encounter severe conditions. In summary, steel wire mesh emerges as a dependable and effective alternative for automotive filters.

- Q:What are the different framing options available for steel wire mesh?

- Depending on the specific application and desired appearance, there are various framing options available for steel wire mesh. A commonly used framing option is a metal frame, typically constructed from steel or aluminum, which offers durability and strength. These frames can be welded or bolted together to create a rigid structure, securely holding the wire mesh in place. Metal frames are often utilized in situations where the wire mesh needs to withstand heavy loads or external forces. Alternatively, a wooden frame is another option, often chosen for decorative purposes or when a more rustic or natural appearance is desired. These frames can be crafted from different types of wood, such as pine or oak, and can be stained or painted to match the surrounding environment. Wooden frames are typically assembled using screws or nails and provide a more flexible and lightweight alternative to metal frames. In addition to metal and wooden frames, frameless options are available for steel wire mesh. Frameless installations involve directly attaching the mesh to a structure or using clamps or brackets. This option is often selected for applications where a minimalist and contemporary appearance is desired or when the wire mesh needs to be easily removable for maintenance or cleaning purposes. Ultimately, the choice of framing option for steel wire mesh depends on factors such as the intended use, desired appearance, and specific project requirements. It is crucial to carefully consider these factors and seek advice from professionals to determine the most suitable framing option for your specific needs.

- Q:Is steel wire mesh suitable for railway applications?

- Yes, steel wire mesh is suitable for railway applications. It provides strength and stability, allowing it to withstand the heavy loads and vibrations experienced in railway operations. Additionally, its durability and resistance to corrosion make it a reliable choice for long-term use in railway infrastructure.

- Q:Can steel wire mesh be used for material handling?

- Yes, steel wire mesh can be used for material handling. Steel wire mesh is a strong and durable material that is commonly used in various industries for handling and transporting materials. It is often used as a base or lining for containers, cages, and pallets to provide support and stability for the materials being transported. Steel wire mesh can also be formed into different shapes and sizes to create custom storage and handling solutions. Additionally, its open design allows for good visibility and ventilation, making it suitable for storing and handling materials that require airflow or visual inspection. Overall, steel wire mesh is a versatile material that can effectively be used for material handling purposes.

- Q:What are the cost considerations for steel wire mesh?

- When considering the costs of steel wire mesh, there are several factors to take into account. Firstly, the size and dimensions of the mesh will play a significant role in its cost. Larger and more intricate designs will generally be more expensive than smaller and simpler ones. Additionally, the thickness and grade of the steel used in the mesh will also impact the cost. Thicker and higher-grade steel will typically be more expensive due to the increased material cost and potential for higher manufacturing expenses. The quantity of steel wire mesh required for a project is another crucial consideration. Purchasing in bulk or larger quantities may often lead to volume discounts and lower unit costs. On the other hand, smaller quantities may result in higher prices due to increased handling and packaging costs. Furthermore, the complexity of the manufacturing process can affect the cost of steel wire mesh. Certain designs may require more intricate weaving or welding techniques, which can increase the labor and production expenses. Additionally, if specialized equipment or tools are needed for manufacturing, it can also contribute to higher costs. Transportation and delivery costs should also be considered. The weight and size of steel wire mesh can impact shipping expenses, especially if the product needs to be transported over long distances. Lastly, market conditions and fluctuations in the price of steel can influence the cost of steel wire mesh. As steel is a commodity, its price can vary based on supply and demand factors, as well as global economic conditions. Therefore, it is essential to monitor market trends and factor in potential price changes when considering the overall cost of steel wire mesh.

- Q:What are the different mesh opening shapes available in steel wire mesh?

- The different mesh opening shapes available in steel wire mesh include square, rectangular, hexagonal, diamond, and oblong shapes.

- Q:Can steel wire mesh be used for waste baskets?

- Yes, steel wire mesh can be used for waste baskets. It is a durable and sturdy material that provides good ventilation and allows for easy visibility of the contents inside the waste basket. Additionally, steel wire mesh is easy to clean and maintain, making it a suitable choice for waste disposal.

- Q:What are the potential disadvantages of using steel wire mesh?

- Using steel wire mesh in various applications has several potential drawbacks. One major disadvantage is its high cost in comparison to other materials. Manufacturing and installing steel wire mesh can be expensive, making it less accessible for projects with limited budgets. Another drawback is the weight and bulkiness of steel wire mesh. It can be significantly heavier than alternative materials, which can pose challenges in terms of handling and transportation. Moreover, its bulkiness can restrict its use in applications where space is limited. Corrosion is also a potential issue with steel wire mesh. Despite its resistance to rust, steel wire mesh can still corrode over time, especially in harsh environments or if not properly maintained. This corrosion can weaken its structural integrity and reduce its overall lifespan. Additionally, steel wire mesh is susceptible to damage and breakage. Its relatively thin and flexible nature makes it prone to bending, warping, or tearing under certain conditions. This can be problematic in high-impact or heavy-load situations where the mesh may not provide adequate strength or stability. Lastly, steel wire mesh may not be suitable for projects that prioritize visual appeal or architectural aesthetics. It tends to have a utilitarian appearance, which may not align with certain aesthetic or design preferences. In conclusion, while steel wire mesh offers advantages such as strength, durability, and versatility, it is important to consider these potential disadvantages before deciding to use it in a specific application.

- Q:What are the benefits of using steel wire mesh in the textile refurbishing industry?

- Steel wire mesh is a versatile material that offers numerous benefits in the textile refurbishing industry. Firstly, it provides a strong and durable support structure for fabrics during the refurbishing process. This is particularly important when handling delicate or fragile textiles, as the steel wire mesh prevents damage and distortion while the fabric is being worked on. Additionally, steel wire mesh allows for better airflow and ventilation during the refurbishing process. This is crucial for drying fabrics, as it helps to prevent the growth of mold and mildew. The open structure of the mesh also facilitates the application of chemicals or dyes, ensuring an even and consistent distribution. Another advantage of using steel wire mesh is its resistance to corrosion and wear. This makes it suitable for use in wet or humid environments, as well as in situations where fabrics may come into contact with chemicals or cleaning agents. Steel wire mesh is also easy to clean and maintain, ensuring longevity and cost-effectiveness for textile refurbishing businesses. Moreover, steel wire mesh offers excellent stability and support for stretching fabrics during the refurbishing process. This is particularly important when working with curtains, upholstery, or other textiles that require precise measurements and alignment. The mesh's strength and rigidity ensure that fabrics can be stretched and secured evenly, resulting in a professional and polished finish. Lastly, steel wire mesh is a sustainable choice for the textile refurbishing industry. It is a recyclable material, reducing waste and environmental impact. By using steel wire mesh, textile refurbishing businesses can contribute to a more sustainable and eco-friendly approach to their operations. In conclusion, the benefits of using steel wire mesh in the textile refurbishing industry are numerous. It provides strength, durability, and stability to fabrics, allows for better airflow and ventilation, resists corrosion and wear, offers easy maintenance, and contributes to sustainability. Incorporating steel wire mesh into textile refurbishing processes can greatly enhance the efficiency, quality, and longevity of the finished products.

- Q:Can steel wire mesh be used for insect screening?

- Yes, steel wire mesh can be used for insect screening. Steel wire mesh is known for its durability and strength, making it an effective material for keeping insects out of homes, buildings, and other enclosed spaces. The tight weave of the steel wire mesh prevents insects from entering while still allowing air circulation and visibility. Additionally, steel wire mesh is resistant to rust and corrosion, ensuring its longevity and effectiveness as an insect screen.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low carbon steel expanded metal mesh (manufacturer )

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords