LOG-90S8 injection molding machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 3751-6340 g

Clamping Force: 11000 kn

Opening Stroke: 1150 mm

Power(W): 45+45 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 100-110-120-130 mm

Space between Tie Bar: 1150*1100

Ejector stroke: 350mm

Ejector force: 270 kn

Oil Tank Capacity: 2300L

S8 series Rexroth servo motor energy-saving machine

S8 Series features

Hydraulic closed loop and motor speed closed loop is realized by control system with the features of high repetition, high linearity, high efficency , and long service life. High-rigidity template design with T shot and ordinary threaded hole facilitates the mold installation. Oil filter equipment of high performance and high precision can keep the grease within NAS8. Colored control system is adopted.

SPECIFICATION OF LOG 90 S8 CRATE INJECTION MODLING MACHINE

LOG-90S8 | ||||

International size rating | 275/90 | |||

INJECTION | A | B | C | |

Shot volume | cm3 | 113 | 154 | 181 |

Shot weight | G | 106 | 144 | 170 |

OZ | 3.7 | 5.1 | 5.9 | |

Screw diameter | mm | 30 | 35 | 38 |

Injection pressure | mpa | 243 | 179 | 152 |

Screw L:D ration | 20:1 | 20:1 | 18:1 | |

Screw stroke | mm | 160 | ||

Screw speed(stepless) | r/min | 0-180 | ||

CLAMPING UNIT | ||||

Clamping force | kn | 900 | ||

Opening stroke | mm | 320 | ||

Platen size | mm×mm | 540×540 | ||

Space between fie bars | mm×mm | 360×360 | ||

Mold fhickness(Min-Max) | mm | 150-360 | ||

Max.daylingt | mm | 680 | ||

Hydraulic ejection stroke | mm | 100 | ||

Hydraulic ejection force | kn | 31 | ||

POWER UNIT | ||||

Hydraulic system pressure | mpa | 16 | ||

Max.motor current | A | 38 | ||

Heating capacity | kw | 6.5 | ||

Number of femp confrol zones | \ | 3+ nozzle | ||

GENERRL | ||||

Dry-cycle fime | Sec | 1.1 | ||

Oil fank capacify | λ | 160 | ||

Machine dimensions | m×m×m | 4.5×1.1×1.7 | ||

Machine weight | kg | 3500 | ||

Product range:90ton----2200ton

Engry saving machine with servo system

PVC special

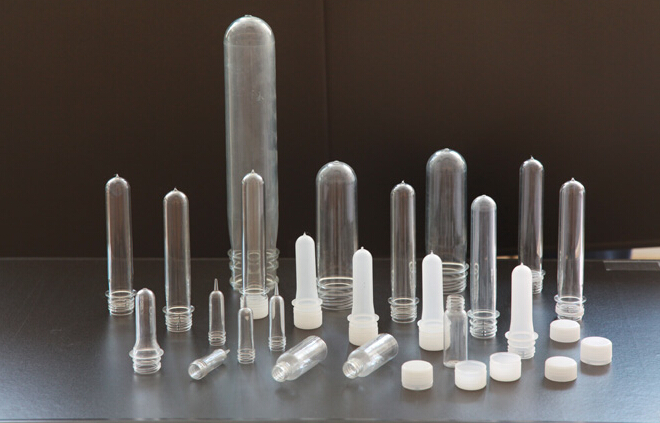

PET special

Energy Saving

Servo energy-saving injection molding machine ,there is no extra energy consumption due to output volume changes according to load.the cooling motor doesn't work and consumes no energy ,Servo energy-saving injection molding machines will save 20%-80% energy and bring you.

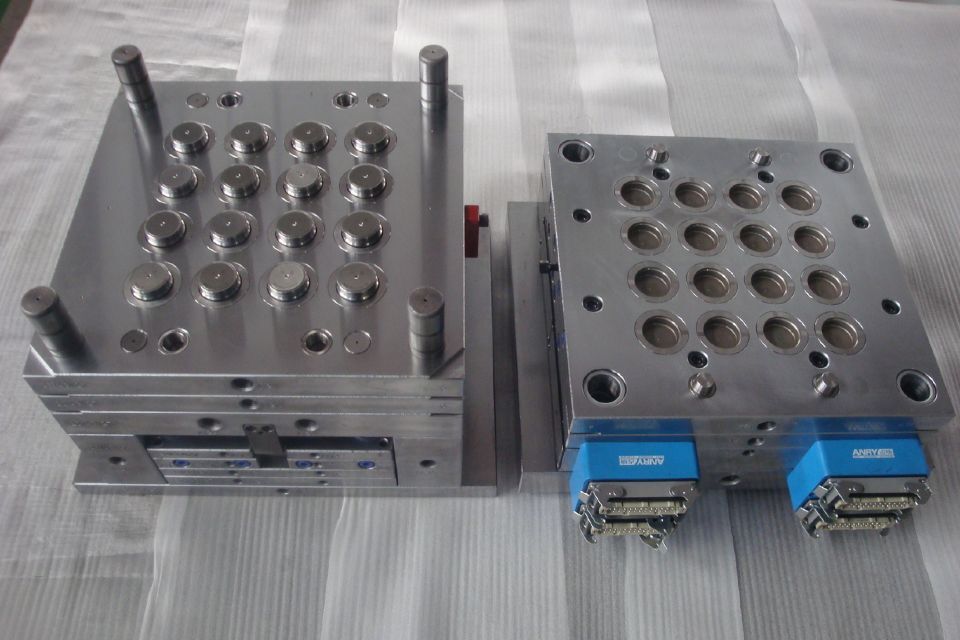

product mold

Packing detial:according to customer requirments

Delivery detial: 15-30days

- Q:How do you increase your product? How do you assign multiple segments? Speed? How to determine the holding position? Big, good or small? All help answer! Be deeply grateful!

- The size of each of the products are different in nature, the machine method is not the same, increase the product I will generally use four, the first section of second section is walking the gate, go to watch it go gum products, is to prevent it, trapped gas or gas lines, third pressure faster than second some a little slower, the vantage point to almost full gum, last paragraph third paragraph is used as an outlet, the rate dropped to 10 or 15, the pressure to about 65, he shot to see which position began to pressure the pressure point is set to fourth position, if the material is difficult to shrink a good tune, put on three to Paul has shrunk, such as the first stage pressure 10, speed 15, 0.5 seconds, second pressure 20, speed 25, a second time, third pressure of at least 130 or more, the speed of not more than 45, at least 4 seconds If not, cut the amount of the first and second periods to control shrinkage. Of course there are sure to barrel temperature, mold temperature, get well, water or oil are related to important. I can answer that for you so far. Honestly, I've only been studying for 9 months so far. I've got everything to learn there. In fact, I want to be familiar with this line and practice more

- Q:Renovation and maintenance treasure source injection molding machine, material, pipe, screw, how much money?

- Treasure how many tons of tonnage, small tonnage, there is no need to renovation, and not cost-effective, the source of treasure machine cylinder, some have in stock

- Q:What an elder brother knows how nitrogen injection is going on. What should I pay attention to?

- 1. the operator must undergo good safety education.2. operate strictly according to the operating rules of equipment.3., when the valve operation, wear protective equipment: masks, gloves, etc., to prevent frostbite.4. check the safety valve and pressure gauge once a year, check the riot film every two years, check and record the records.5. when the nitrogen emissions, people should stay away from the drain, otherwise, long time suffocate easily.6. in the obvious place to hang around the nitrogen tank "trespassers", "dangerous" and other warning signs.7. freezing on nitrogen pipe, no heavy blow.8. check the nitrogen tank every day and find the problem in time.9. always keep the nitrogen tank clean and free of oil and grease.10. equipment should be cut off for a long time without gas.

- Q:What kind of metal material is the nozzle head of injection molding machine?

- Screw is an important part of injection molding machine. Its function is to transport, compact, melt, stir and press the plastic. All this is done by rotating the screw in the barrel. When the screw rotates, the plastic will cause friction and movement between the inner wall of the cylinder, the bottom of the screw, the bottom of the screw, the advancing surface of the screw and the plastic and plastic.Often used to produce screw material:1, 38CrMoAla2, SACM6453, 42CrMo4, 9Cr18MoV5, SKD616, tungsten carbide alloy, tungsten carbide nickel based alloy7 、 fully hardened powder alloy (Quan Hejin)8, high temperature alloy

- Q:The first paragraph of the injection molding machine does not rise in temperature. What's the matter?

- The heating ring is badShort circuit burnoutAC contactor damageThe fuse tube is burnt outChasing the answerSwitch trip6: temperature line connection error or damage

- Q:What are the equipments around the injection molding machine?

- Injection molding machine auxiliary machine, namely injection molding machine auxiliary equipment and injection molding machine peripheral equipment.Auxiliary machine is a complete set of auxiliary equipment: can be divided into processing auxiliary equipment and injection molding production and other auxiliary equipment.Auxiliary equipment of injection molding machine includes: strong crusher, machine speed slow, industrial chiller, mold temperature control machine, dryer, color mixer, automatic packing machine, automatic milling machine, industrial water tower machine, machine equipment accessories and other auxiliary equipment of injection molding machine.

- Q:How does the steel injection machine go to the origin?

- 2, the low voltage protection pressure is set to 0, then the injection molding machine is set to a low pressure hand, repeatedly closed die mold at low pressure required to set the position (the actual position), with low pressure minimum, each increase of 1%, to turn to the low voltage clamping pressure, pressure for low voltage protection we should set.

- Q:How does the product mix?

- Friends note plastic flowers (silver or silver) of good hope to help?Silver good resolution?Production of raw materials: good drying. The heating barrel degassing Liang (water, gas, volatile, etc.), gas burning retention solutions, mould heating involved (including type changes are good flesh) shaped silver prototype surface show silver floating flow area not only limited traces of silver near the gate of primary and reflected out parts closely related, must understandTwo. Production: the so-called silver silver diagram shown in figure refers to the molten resin in bubbles, tensile effect of muscle strips flow marks because of the appearance of the silver bullion that look like muscle strips

- Q:Now I know a product of the material cost unit (single weight + nozzle), but how to calculate artificial + factory rent + machine wear + Plus transport + packing material, seek heroes pointing. emergency

- Cost accounting of injection molding parts1, what is the average acquisition factor?The consumption factor is divided into two cases:One, you can add water mouth material, 2%-5%Two can not add water mouth material, single mode nozzle weight / (single mode nozzle + finished product) +2% to 5%Remarks: the material of the gate can be returned to the processing master, otherwise the material of the nozzle should be discounted, and the quantity of the order should also be referred to2, different equipment, tonnage, hole number, time difference, what are the formulas?First, the price of different tonnage; 150 tons -800 to 1000 yuan / day, 120 tons -600 to 800/ days, the specific situation depends on the number of operators (a machine, a few people do)Two, daily (24 hours) beer modulus; generally from 20 to 22 hours meter (possible machine, die failure)20 (HR) *60 (min) *60 (second) / single-mode cycle (second) = daily modulus of beerPer unit price = daily processing fee / daily plastic modulus per unit price = beer per unit / hole numberSecond question may be more complex, if not specific to say, then can you give me a range, or give me a sample, such as what equipment, under what circumstances, the processing cost is?For example, 150 tons of injection molding machine processing costs 1000 yuan per day, each mold cycle 20 seconds 8 points20 (hours) *60 (minutes), *60 (SEC), /20, single-mode cycles (seconds), =3600 (beer modulus per day)1000 yuan /3600=0.28 yuan / model 0.28 yuan, /8 point =0.035 acupuncture point3, where can I find the cost of different injection molding machines? How do you calculate the consumption of ordinary machines?Injection molding machine consumption generally 8 years countExamples are 150 tons, 130 thousand per set130 thousand /8 months /12 months =0.1354 million / month

- Q:How can the neutron pipe of Haitian injection machine be connected?

- In general, the electromagnetic valve thimble interface neutron and neutron valve plate are generally divided into a plurality of groups of solenoid valve into the oil outlet (i.e. neutron and choose one) on the import interface on a test at a glance. If the action is wrong, the oil pipe can be switched on

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LOG-90S8 injection molding machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords