LLDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LLDPE Geomembranes

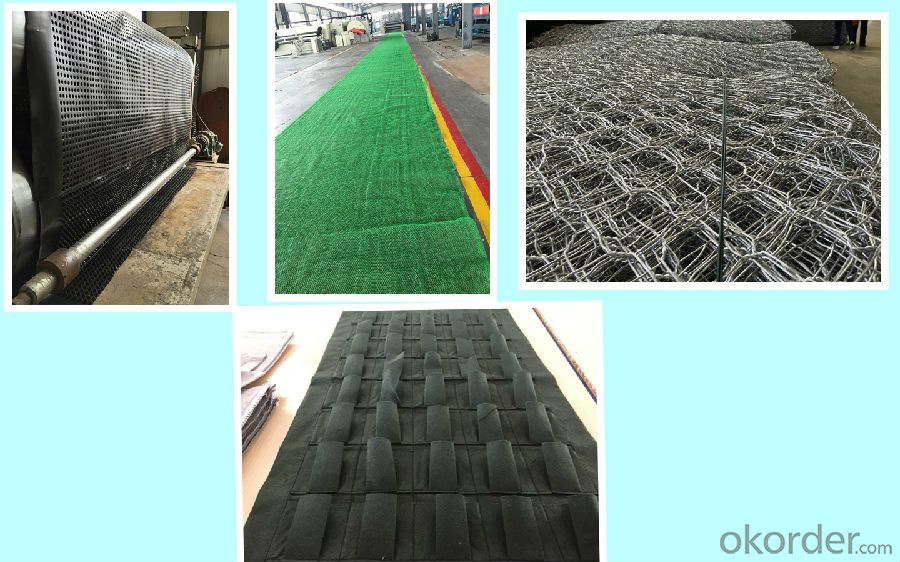

LLDPE Geomembranes Description

Made from LDPE, LLDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

LLDPE Geomembranes Application

1. Agricultural water conservancy projects.

2. Ponds for aquaculture.

LLDPE Geomembranes Advantages:

1. High flexibility, high waterproof coefficient.

2. Could be used in the temperature of -70 ℃~110 ℃.

3.Good stability, anti acid and alkalis,anti-erosion.

4.High climate bearing ability, excellent in anti-aging.

5.High tensile strength and elongation, can be used in bad geology and climate, especially be used in the soil uneven sedimentation.

6.High friction coefficient.

LLDPE Geomembranes Specification

1. Thickness: 0.1mm to 3.0mm.

2. 4m-9m in roll width, roll length as design or client's request.

LLDPE Geomembranes Characteristics

1.HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and resistance to puncture .

2.LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy installation.

3.ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:Can geomembranes be used for stormwater management?

- Yes, geomembranes can be used for stormwater management. They are commonly employed as liners in stormwater ponds, retention basins, and other storage systems to prevent water from seeping into the ground. Geomembranes can effectively control water flow, minimize soil erosion, and provide a barrier to contaminants, making them a suitable choice for stormwater management applications.

- Q:How do geomembranes contribute to the prevention of soil erosion?

- Geomembranes contribute to the prevention of soil erosion by acting as a barrier between the soil and external forces such as water, wind, or chemicals. They provide a protective layer to the soil surface, preventing it from being exposed to erosive factors and reducing the risk of erosion.

- Q:How do geomembranes contribute to protection of buried pipelines?

- Geomembranes contribute to the protection of buried pipelines by acting as a barrier between the pipeline and the surrounding soil or environment. They provide a protective layer that helps prevent corrosion, abrasion, and damage from external factors such as chemicals, moisture, and root penetration. Additionally, geomembranes can enhance the overall structural integrity of the pipeline by distributing external loads and reducing the risk of settlement or deformation.

- Q:Introduction of geomembrane

- Geomembrane plastic film used as seepage-proof base material and combined with woven cloth geotechnique seepage-proofing material new material geomembrane anti-seepage property mainly depends on plastic film anti-seepage property at present at home and abroad seepage-proof application plastic film mainly include polyvinyl chloride (PVC) and polyethylene (PE), EVA (ethylene / vinyl acetate copolymer), tunnel practical design using ECB (blending geomembrane of ethylene-acetic acid-ethylene modified asphalt) a kind of high polymer chemistry flexible material, with small proportion, strong extensibility, high?adaptability?to the?deformation, corrosion resistance, low temperature resistance and good anti-frost property.

- Q:What are the advantages of using geomembranes in stormwater management?

- One advantage of using geomembranes in stormwater management is their ability to prevent the infiltration of contaminants into the ground. By acting as a barrier, geomembranes can effectively contain pollutants and prevent them from seeping into the soil and potentially contaminating groundwater sources. Additionally, geomembranes provide a durable and long-lasting solution for stormwater management, reducing the need for frequent maintenance and repairs. They also allow for greater control over the movement and storage of stormwater, ensuring more efficient and effective management of runoff.

- Q:How good of the quality of waterproof electrothermal?film?

- It's OK.

- Q:What are the factors to consider when selecting a geomembrane?

- When selecting a geomembrane, there are several important factors to consider. These include the specific application or project requirements, such as the type of containment or barrier needed, the expected environmental conditions, and the desired lifespan of the geomembrane. Other factors to consider include the material properties, such as strength, flexibility, and chemical resistance, as well as installation considerations like ease of handling and installation methods. Additionally, cost, availability, and the reputation of the manufacturer or supplier should also be taken into account. Ultimately, it is crucial to carefully evaluate all these factors to ensure the selected geomembrane will meet the project's needs and deliver long-term performance.

- Q:Can geomembranes be used in agricultural applications?

- Yes, geomembranes can be used in agricultural applications. They are commonly used as liners for irrigation ponds, storage tanks, and canals to prevent water seepage and improve water management. They can also be used as covers for manure storage facilities to control odors and reduce contamination. Additionally, geomembranes can be utilized to line agricultural waste containment areas, helping to protect the environment by preventing the leaching of harmful substances into the soil and groundwater.

- Q:Can geomembranes be used in biogas storage systems?

- Yes, geomembranes can be used in biogas storage systems. They are often used as liners to prevent leakage and maintain the integrity of the storage system. Geomembranes are designed to be impermeable and resistant to gas diffusion, making them suitable for containing biogas and preventing any potential environmental risks.

- Q:Waterproof geomembrane hand welding machine where there are selling price

- 3800-7800 range can also be found outside the Association, a special welders bring their own equipment

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LLDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords