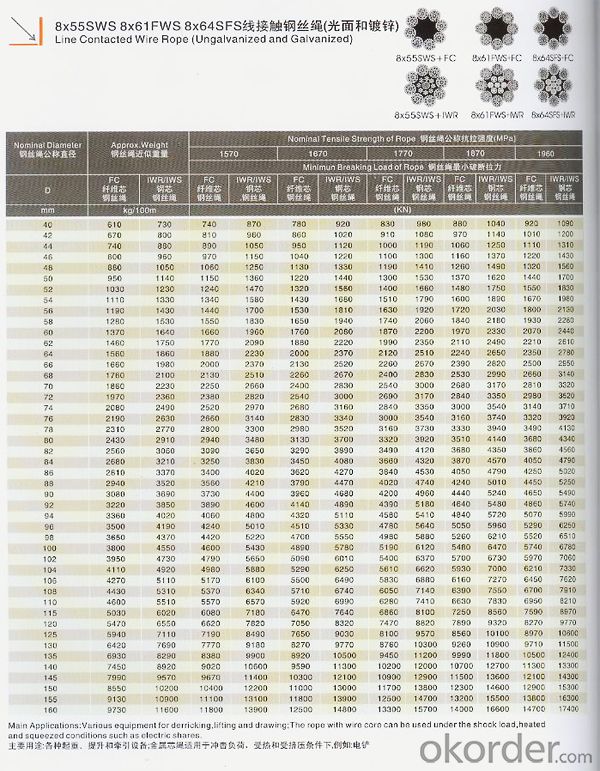

LINEAR CONTACT LAY WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What are the different types of steel sections?

- There are several different types of steel sections, including I-beams, H-beams, U-channels, angles, and T-sections. Each type of section has its own unique shape and structural properties, making them suitable for various applications in construction and engineering.

- Q:How do steel products contribute to the healthcare and medical industry?

- Steel products contribute to the healthcare and medical industry in various ways. Firstly, stainless steel is widely used in the production of medical equipment and surgical instruments due to its durability, corrosion resistance, and ease of sterilization. From scalpels and forceps to prosthetics and implants, steel ensures the reliability and hygiene of these critical tools. Additionally, steel is used in the construction of healthcare facilities, providing strength, stability, and fire resistance. Furthermore, steel is also used in medical storage systems such as cabinets and shelves, ensuring efficient organization and safety of medical supplies. Overall, steel products play a vital role in maintaining the quality, safety, and functionality of healthcare and medical services.

- Q:What are the different types of steel wire ropes and their uses in offshore drilling operations?

- There are various types of steel wire ropes used in offshore drilling operations, including 6x19 and 6x36 constructions. These ropes consist of multiple strands of wires twisted together to provide strength and flexibility. The 6x19 construction is commonly used for drilling lines, while the 6x36 construction is suitable for hoisting and lifting operations. These steel wire ropes are essential in offshore drilling as they provide the necessary strength and support for various tasks, ensuring the safe and efficient operation of equipment and machinery involved in drilling operations.

- Q:How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. Steel is widely used as a structural material due to its high strength, durability, and ability to withstand extreme environmental conditions. It provides the necessary framework for these complex structures, ensuring their stability and longevity. Additionally, steel is often used in specialized equipment and infrastructure within the laboratories, such as fume hoods, ventilation systems, and lab benches. Its versatility and adaptability allow for the creation of customized solutions to meet the unique needs of scientific research. Overall, steel products contribute significantly to the construction and functionality of research laboratories, facilitating the advancement of scientific knowledge and innovation.

- Q:How do steel products contribute to the aerospace industry?

- Steel products contribute to the aerospace industry in several ways. Steel is commonly used in the construction of aircraft structures, such as fuselages, wings, and landing gears, due to its high strength-to-weight ratio. It provides the necessary strength and durability required to withstand the extreme conditions of flight. Additionally, steel is used in the manufacturing of various components, such as fasteners, bolts, and bearings, which are crucial for ensuring the safety and reliability of aircraft. Overall, steel products play a vital role in the aerospace industry by providing structural integrity, enhancing performance, and ensuring the longevity of aircraft.

- Q:How does steel pipe threading work?

- Steel pipe threading is a process where a machine is used to cut threads into the ends of steel pipes. The machine grips the pipe securely and rotates it while simultaneously cutting or forming the threads using a die or cutting tool. This creates a threaded connection that can be used to join pipes together or attach fittings, ensuring a tight and secure seal. Threading is commonly used in plumbing, construction, and industrial applications.

- Q:What are the properties of stainless steel for medical applications?

- Stainless steel for medical applications possesses several important properties that make it an ideal material. Firstly, it is highly resistant to corrosion, which is crucial in medical settings where exposure to bodily fluids and harsh cleaning chemicals is common. Secondly, stainless steel is biocompatible, meaning it does not cause adverse reactions or toxicity when in contact with the human body. Additionally, it is highly durable and can withstand repeated sterilization processes without compromising its integrity. Moreover, stainless steel is easy to clean and maintain, ensuring a hygienic environment for medical procedures. Lastly, it has excellent strength and versatility, allowing it to be used in a wide range of medical devices and equipment.

- Q:How is steel tubing used in the oil and gas industry?

- Steel tubing is commonly used in the oil and gas industry for various applications such as drilling, production, and transportation of oil and gas. It is used for casing and tubing in oil wells to provide structural support and prevent collapse. Steel tubing is also utilized in pipelines to transport oil and gas over long distances, as it offers high strength, durability, and resistance to harsh environments. Additionally, steel tubing is used in the manufacturing of equipment and machinery used in the extraction and refining processes of oil and gas.

- Q:How are steel forgings used in the aerospace industry?

- Steel forgings are widely used in the aerospace industry due to their exceptional strength, durability, and resistance to extreme conditions. These forgings are utilized in critical aerospace components such as landing gear, turbine discs, engine mounts, and structural parts. With their ability to withstand high temperatures and pressures, steel forgings ensure the reliability and safety of aircraft, enabling them to perform optimally in demanding environments.

- Q:What are the properties of stainless steel for medical equipment?

- Stainless steel for medical equipment exhibits several key properties such as high corrosion resistance, excellent strength and durability, good heat resistance, and ease of sterilization. It is also non-reactive, biocompatible, and resistant to bacteria growth, making it a suitable material for surgical instruments, implants, and other medical devices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LINEAR CONTACT LAY WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords