Lightweight Ceiling Board, XPS Grooved Insulation Board, Polystyrene Decorative Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation & waterproofing solutions - CMAX Lightweight Ceiling Board

Product name:

CMAX board (as known as construction board, tile backer board, insulation backer board, waterproof backer board, wet room backer board, XPS board.)

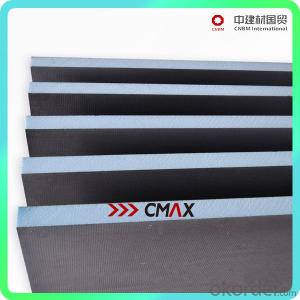

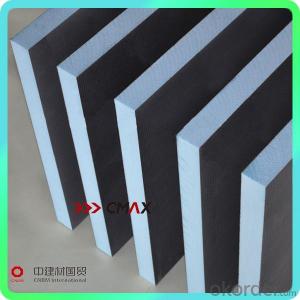

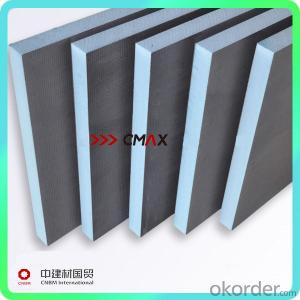

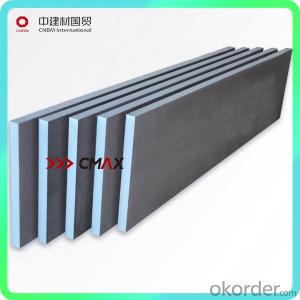

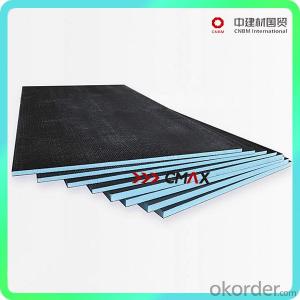

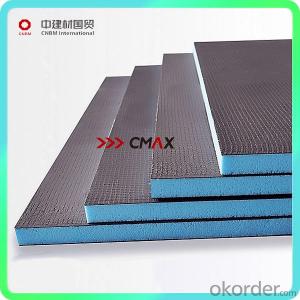

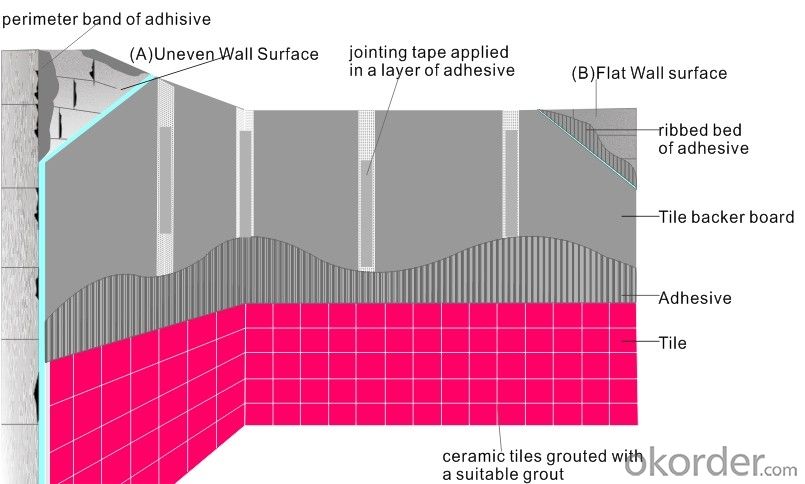

Product structure:

CMAX boards are made of high-performance waterproof extruded polystyrene (XPS Board), it has a 0.75mm coating on either side comprising a glassfiber mesh embedded in a polymer cement mortar.

Outstanding characteristics Lightweight Ceiling Board:

Both insulation and waterproof.

Product appearance Lightweight Ceiling Board:

The boards have straight edges. The color of the surface is grey and the core material is light blue.

Working temperature range Lightweight Ceiling Board:

50 to +80 °C

Standard dimensions and weight Lightweight Ceiling Board:

Thickness(mm) | Weight(kg/m²) | Length by width(mm*mm) |

6 | 2,7 | 1200 x 600 |

10 | 2,9 | 1250 x 600 |

12 | 3,0 | 2500 x 600 |

20 | 3.1 | 2500 x 600 |

30 | 3,3 | 2500 x 600 |

50 | 4,2 | 2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to Fire Lightweight Ceiling Board:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment Lightweight Ceiling Board:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declarationLightweight Ceiling Board:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications Lightweight Ceiling Board:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications Lightweight Ceiling Board:

Other places to be insulated and waterproofed.

Applications:

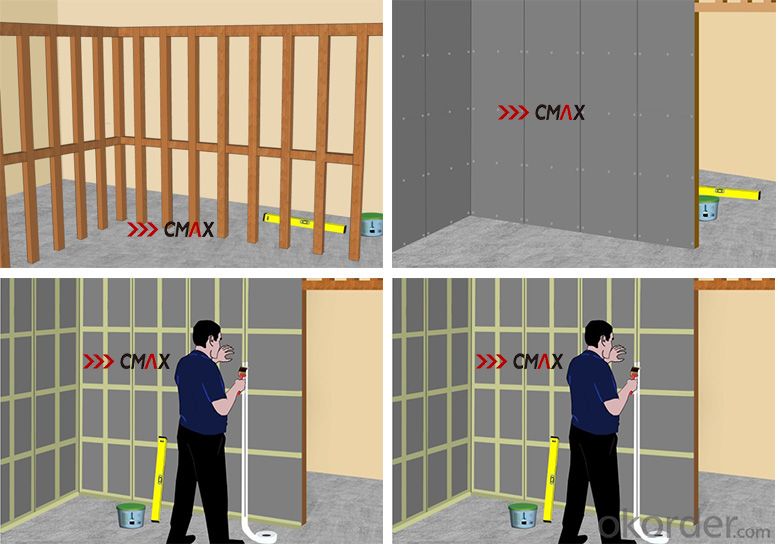

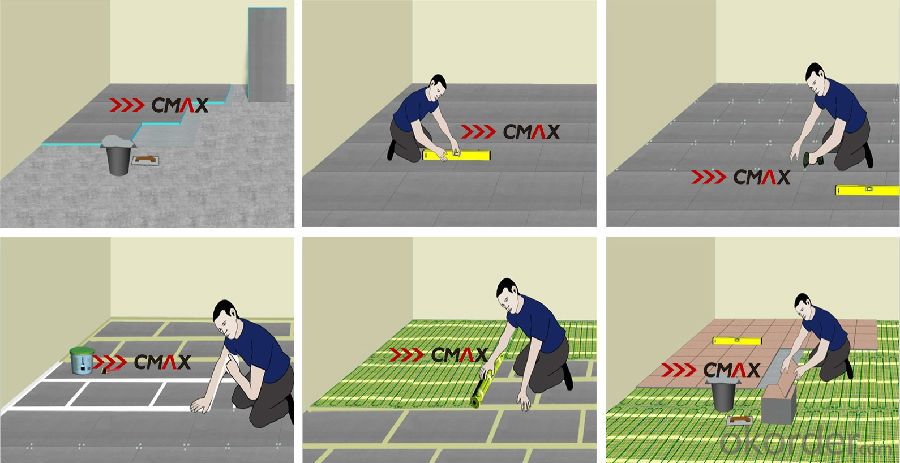

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

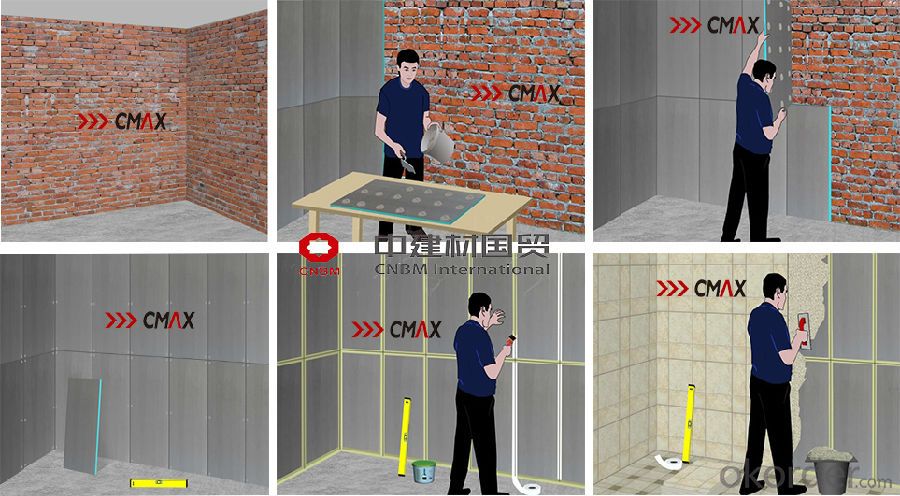

Fixing:

Choose a way to fix CMAX board according to the substrate to be fixed. Normally, using modified tile adhesive for solid concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel frames.

Reinforcement:

1. Dry areas: reinforce all joints between boards, floors and walls by 125px or 250px wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

FAQ:

1.

Q: Are you a manufacturer of insulation materials?

A: Yes. ourselves manufacturer of thermal insulation board.

2.

Q: What is the seaport near your plants?

A: The nearest port is Shanghai Port, there are about 100km from the port to our plant in Shanghai.

3.

Q: What is annual production capacity of your main products?

A: 200,000 piecs per month.

4.

Q: Do you have your own brands? And what are they.

A: Yes. we are a fortune 500 company, our brand is "CMAX"

5.

Q: Is sample available for testing?

A: Yes. The sample is free.

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Panasonic refrigerator with the world's leading vacuum insulation material Vacuuminsulationpanel (referred to as VIP) vacuum insulation board, is developed in recent years, a new type of highly efficient insulation material, which uses vacuum insulation principle, under vacuum conditions, the thermal conductivity is very low , Widely used in household appliances. The product to fill the gaps, is a leading international high-tech products. . VIP in the production and application process does not use ODS substances. . the insulation layer of the same thickness, you can save energy. . the same energy consumption, VIP can reduce the thickness of the insulation layer to reduce the volume of objects, increase storage space. . VIP design engineers can provide a variety of flexible options. . CFC consumption of ozone, destruction of the ecological environment, if the alternative blowing agent, its high thermal conductivity, reducing the thermal insulation properties of the foam, although the environmental protection, but need to consume more energy, and VIP is environmentally friendly And the dual advantages of energy saving. . VIP on environmental protection and national energy conservation has a great contribution. . VIP thermal conductivity is PU one-eighth, is the replacement of insulation materials. Vacuum insulation panel (VIP) technology industry has quickly formed a practical industry trends, and industry-class enterprises to adopt. Was rated as energy-saving refrigerator model products which is the use of VIP technology to achieve energy-saving purposes. (BCD-239DVC), Panasonic "energy saving king" refrigerator (NR-E461U), the new energy-saving "Golden Eagle" refrigerator (BCD-218E) Meiling "digital energy-saving Wang" refrigerator (BCD-239DVC) BCD-200A / HC, BCD-270A / HC and other six models (BCD-219U / C), the best energy-saving refrigerators, including BCD-180A / HC, BCD-200A / HC, BCD-270A / HC and other six models Wait.

- Q:How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- The honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The First play expansion bolts, do insulation, can say the details of the point. There is that you can use .7 inside the expansion of the screw, to Fu Fu Huang Peng, You can also use welding, then a long screw, is also very simple.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Caigang rock wool sandwich panel Scope Caigang rock wool sandwich panels for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling , Cut off and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding the right amount of binder, curing processing and made. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on. Color rock wool sandwich panels Product Features 1. Rock wool is inorganic insulation materials, iron ore slag as the main raw material, by melting, with high-pressure steam jet cooling, with a light, thermal conductivity is small, good elasticity , Non-combustible, non-rotting, non-rotting, chemical stability, and excellent sound insulation.2 The rock wool sandwich panels are widely used in addition to the general structure of heat insulation and insulation To the use of a variety of fire insulation places. Caigang rock wool sandwich board specifications thickness Caigang rock wool sandwich board sub-system board and manual board two, Caigang sandwich panel is made of two layers of color coated steel Layer, through the automatic compound molding machine, in the steel plate coated with adhesive glue, while embedded in the board on both sides of the thin-walled steel, the pressure, blanking made of sheet metal. . the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × . L × 1150 × . L × 1150 × . handmade rock wool color steel sandwich panel specifications: L × 985 × . Sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. . rock wool density: ≥ 120kg / m. thermal conductivity: ≤ 0.046w / m.k. combustion performance: A-level (non-combustible)

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q:Why extruded board (XPS board) is the best insulation board material

- Scaffolding from the erection of the main points on the scaffolding, cantilevered scaffolding and climbing three. High-level general use of floor and cantilever set of set enough to set the dumplings rush to set off the boat to Long. If the number of layers to more than 30F, and the structure can be relatively simple climbing scaffolding, climbing the advantage of the higher the height of the higher relative to the cost of picking. I am a professional scaffolding company, do not understand can ask me. I hope I can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lightweight Ceiling Board, XPS Grooved Insulation Board, Polystyrene Decorative Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords