Light weight FRP pultruded grating and Pultrusion Process on sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenolic resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.Packaging Details:

plastic film and pallet

2.Delivery Detail:

In 5 days after receiving the down payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

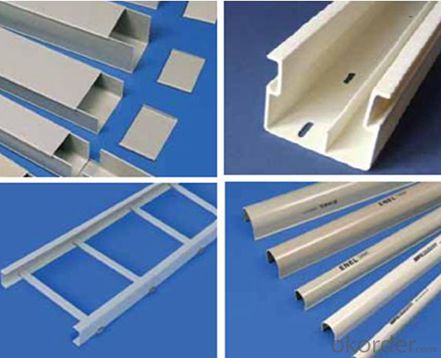

PICTURES

- Q:What is the maximum length of FRP pultrusion profiles that can be manufactured?

- The maximum length of FRP (Fiber Reinforced Polymer) pultrusion profiles that can be manufactured depends on various factors such as the specific manufacturing process, equipment capacity, and transportation limitations. In general, FRP pultrusion profiles can be manufactured in lengths ranging from a few feet to several hundred feet. However, there are certain practical limitations that need to be considered. Firstly, the length of the pultrusion profiles is often limited by the size and capacity of the pultrusion equipment used in the manufacturing process. Different pultrusion machines have varying capabilities, and their length capacities can range from a few feet to over 100 feet. Manufacturers must consider the available equipment and its limitations when determining the maximum length of the profiles they can produce. Additionally, transportation and logistical constraints may also impact the maximum length of FRP pultrusion profiles. Longer profiles can be more challenging to transport due to restrictions on road transport, shipping containers, or handling capabilities. These limitations may vary depending on the region, infrastructure, and transportation methods available. It is important to note that longer profiles may also face challenges in terms of quality control and dimensional stability during manufacturing. As the length increases, it becomes more difficult to maintain consistent mechanical properties and control the curing process effectively. Therefore, while there is no fixed maximum length for FRP pultrusion profiles, it is crucial for manufacturers to consider the technical capabilities of their equipment, transportation logistics, and quality control factors when determining the practical limit for the length of their products.

- Q:Can FRP pultrusion profiles be used in the aerospace industry?

- FRP pultrusion profiles are suitable for use in the aerospace industry. They possess several advantages that make them ideal for aerospace applications. Firstly, their high strength-to-weight ratios are crucial in the aerospace industry, where weight reduction is a top priority. This lightweight quality contributes to fuel efficiency and increased payload capacity. Secondly, FRP profiles have excellent corrosion resistance, making them perfect for aerospace applications that involve exposure to harsh environments like high altitude, extreme temperatures, and moisture. This resistance ensures the durability and longevity of the components, reducing maintenance and replacement costs. Additionally, FRP materials can be customized to meet specific design requirements, allowing engineers to easily create complex shapes and structures. This flexibility in design leads to enhanced performance and functionality in aerospace applications. Moreover, FRP pultrusion profiles exhibit exceptional fatigue resistance, enabling them to withstand the cyclic loading and stress cycles commonly encountered in aerospace operations. This characteristic ensures the reliability and safety of the components, which is paramount in the aerospace industry. Furthermore, FRP materials offer electrical insulation properties, which can be advantageous in aerospace applications where controlling or minimizing electrical conductivity is necessary. This insulation capability contributes to the overall safety and functionality of the components. In conclusion, FRP pultrusion profiles are a viable and attractive choice for various aerospace applications, including aircraft structures, interior components, radomes, and others. Their high strength-to-weight ratios, corrosion resistance, flexibility in design, fatigue resistance, and electrical insulation properties make them a suitable option for the aerospace industry.

- Q:Are FRP pultrusion profiles resistant to chemicals used in agricultural applications?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in agricultural applications. FRP (Fiber Reinforced Polymer) composites have excellent chemical resistance properties, making them suitable for various agricultural environments. These profiles can withstand exposure to fertilizers, pesticides, herbicides, and other chemicals commonly used in agricultural applications without experiencing degradation or damage.

- Q:Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath, then through a heated die to cure the resin and form the desired shape. This process allows for great flexibility in design and customization. The customization options for FRP pultrusion profiles include various dimensions, shapes, colors, and surface finishes. The dimensions can be tailored to meet specific length, width, and thickness requirements. The shapes can range from basic geometries like rectangular or round profiles to more complex designs with custom cross-sections. In terms of color, FRP pultrusion profiles can be pigmented during the manufacturing process to achieve the desired color or can be painted or coated afterwards. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Furthermore, surface finishes can be customized to achieve desired properties such as increased slip resistance, UV resistance, or fire resistance. Surface treatments like sanding, coating, or adding special additives can be applied to meet specific performance requirements. Overall, FRP pultrusion profiles offer a high level of customization to meet specific project or application needs. They are versatile, lightweight, corrosion-resistant, and have excellent strength-to-weight ratios, making them suitable for various industries such as construction, transportation, infrastructure, and aerospace.

- Q:Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. These profiles offer excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various applications in the industry such as pipe supports, cable trays, handrails, and platforms. Additionally, FRP pultrusion profiles are non-conductive, non-magnetic, and possess good fire-retardant properties, making them a safer alternative to traditional materials in hazardous environments.

- Q:What are pultrusion materials used for?

- Pultrusion is a kind of glass fiber forming process, the main raw materials are glass fiber and resin

- Q:Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

- Q:Are FRP pultrusion profiles resistant to hydrocarbons?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to hydrocarbons. The combination of various reinforcing fibers such as fiberglass or carbon fiber with a polymer matrix makes FRP materials highly resistant to chemical corrosion, including hydrocarbons. This resistance makes FRP pultrusion profiles a suitable choice for applications where exposure to hydrocarbons is expected, such as in oil and gas industry, chemical processing plants, or fuel storage facilities. However, it is important to note that the level of resistance can vary depending on the specific type of resin used in the FRP material and the concentration and temperature of the hydrocarbons involved. Therefore, it is recommended to consult with the manufacturer or supplier of the FRP pultrusion profiles to ensure their compatibility with the specific hydrocarbon environment in question.

- Q:What is the cost of FRP pultrusion profiles compared to other materials?

- The cost of FRP (Fiber Reinforced Polymer) pultrusion profiles can vary depending on several factors such as the specific application, size, complexity of design, and quantity required. However, in general, FRP pultrusion profiles tend to be more cost-effective compared to many traditional materials. When compared to materials like steel, aluminum, or wood, FRP pultrusion profiles often provide a lower overall cost, especially when considering long-term savings. While the initial material cost of FRP pultrusion profiles may be slightly higher than some traditional materials, the benefits and advantages it offers can outweigh the price difference. FRP pultrusion profiles are known for their lightweight nature, high strength-to-weight ratio, corrosion resistance, and durability. These characteristics contribute to reducing transportation costs, installation expenses, and maintenance requirements. Additionally, the long lifespan of FRP profiles ensures minimal replacement or repair costs over time. Moreover, the manufacturing process of FRP pultrusion profiles allows for precise customization, eliminating the need for additional machining or fabrication, which can further reduce costs. The ability to incorporate design features such as integral stiffeners, brackets, and fastening points during the pultrusion process eliminates the need for additional assembly steps, ultimately saving time and money. It is important to note that while FRP pultrusion profiles may have a higher upfront cost compared to some materials, the overall cost-effectiveness and long-term benefits make them a favorable choice in many applications. Each project's specific requirements and considerations should be taken into account when evaluating the cost of FRP pultrusion profiles compared to other materials.

- Q:Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light weight FRP pultruded grating and Pultrusion Process on sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords