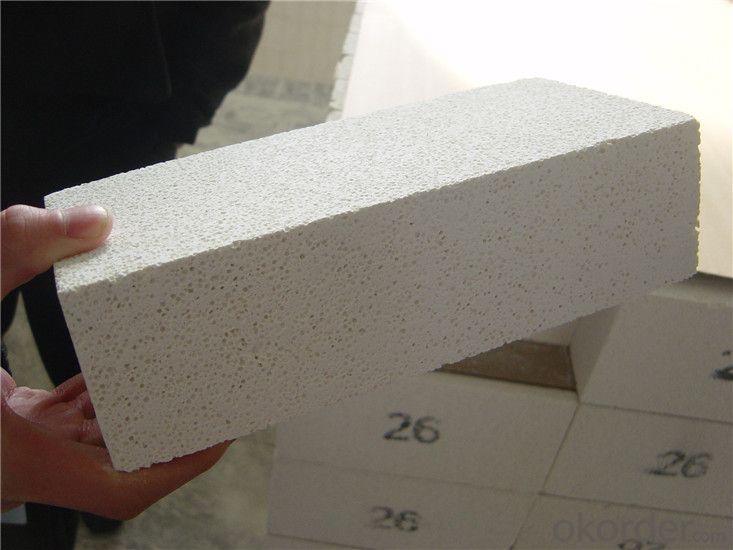

Light weight fire clay for insulating fire brick use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

- Q:Can insulating fire bricks be used in low-temperature applications as well?

- Yes, insulating fire bricks can be used in low-temperature applications. Insulating fire bricks are designed to have high thermal insulation properties, which means they can effectively prevent heat transfer. This makes them suitable for use in both high-temperature and low-temperature environments. In low-temperature applications, insulating fire bricks can help to minimize heat loss and maintain a stable temperature. They can be used to insulate walls, floors, and roofs of structures or equipment that require temperature control, such as cold storage facilities, refrigerators, or freezers. Insulating fire bricks are also commonly used in low-temperature furnaces and kilns, where they help to minimize energy consumption and maintain a consistent temperature throughout the heating process. Their high insulating properties ensure that the heat generated inside the furnace or kiln is effectively contained, reducing heat loss and improving overall energy efficiency. Furthermore, insulating fire bricks are lightweight and easy to handle, making them convenient for various low-temperature applications. They are also resistant to thermal shock and offer excellent structural stability, ensuring long-lasting performance even in challenging environments. Overall, insulating fire bricks can be effectively utilized in low-temperature applications to enhance energy efficiency, temperature control, and structural stability.

- Q:How do insulating fire bricks compare to other refractory materials?

- Insulating fire bricks have a lower thermal conductivity compared to other refractory materials, making them more effective in preventing heat loss. They are also lightweight and have good insulation properties, making them suitable for applications where thermal insulation is crucial. However, they may have lower mechanical strength and higher porosity compared to other refractory materials, limiting their use in certain high-temperature and high-pressure environments.

- Q:Are insulating fire bricks suitable for use in carbon black furnaces?

- Yes, insulating fire bricks are suitable for use in carbon black furnaces. Insulating fire bricks are made from refractory materials that have excellent insulation properties, which makes them ideal for high-temperature applications such as carbon black furnaces. Carbon black furnaces operate at extremely high temperatures, typically above 1,000 degrees Celsius, and the use of insulating fire bricks helps to reduce heat loss and improve energy efficiency. These bricks also have good thermal shock resistance, which is crucial for the cyclic heating and cooling that occurs in the furnace. Additionally, insulating fire bricks have low thermal conductivity, which helps to maintain a stable temperature inside the furnace and prevent excessive heat loss. Overall, insulating fire bricks are a reliable and effective choice for lining carbon black furnaces.

- Q:Can insulating fire bricks be used in the construction of heat recovery systems?

- Yes, insulating fire bricks can be used in the construction of heat recovery systems. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them an ideal choice for heat recovery systems. These bricks are made from lightweight materials, such as ceramic fibers or refractory materials, which have low thermal conductivity. This property allows them to effectively trap and retain heat, preventing it from escaping the system and maximizing energy efficiency. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This makes them suitable for the varying heat conditions often found in heat recovery systems. Overall, using insulating fire bricks in the construction of heat recovery systems can help improve their performance and efficiency by minimizing heat loss and optimizing energy recovery.

- Q:Are insulating fire bricks suitable for insulation in steam boilers?

- Yes, insulating fire bricks are suitable for insulation in steam boilers. Insulating fire bricks are made from lightweight materials that have high insulating properties, such as alumina or silica. They are designed to withstand high temperatures and thermal shocks, making them ideal for use in steam boilers where there is constant exposure to heat. Insulating fire bricks have low thermal conductivity, which means they can effectively prevent heat transfer, reducing energy loss and increasing the efficiency of steam boilers. Their high insulation properties also help to maintain consistent temperatures within the boiler, preventing heat fluctuations and minimizing the risk of thermal stress and damage. Furthermore, insulating fire bricks are resistant to corrosion and chemical attacks, ensuring their durability and longevity in steam boiler applications. They are also easy to install and can be cut into different shapes and sizes to fit the specific requirements of the boiler. Overall, insulating fire bricks are an excellent choice for insulation in steam boilers due to their ability to withstand high temperatures, low thermal conductivity, and resistance to corrosion. They help in reducing energy loss, improving efficiency, and ensuring the longevity of the boiler.

- Q:Can insulating fire bricks be used in the construction of heat storage units?

- Indeed, the utilization of insulating fire bricks is viable in the construction of heat storage units. These bricks are specifically engineered to endure extreme temperatures and possess exceptional thermal insulation properties. They are commonly employed in scenarios where heat retention holds significance, such as furnaces, kilns, and heat storage units. With their low thermal conductivity, these bricks effectively retain and preserve heat for extended durations, rendering them an ideal choice for heat storage units designed to capture and store heat energy for later usage. Additionally, these bricks are lightweight and easy to manipulate, making them a practical selection for construction projects. All in all, incorporating insulating fire bricks into the construction of heat storage units is a suitable and dependable option.

- Q:How long do insulating fire bricks last?

- Insulating fire bricks have been designed to endure high temperatures and offer exceptional insulation properties. The duration of their lifespan can differ based on various factors, such as the quality of the bricks, the temperature they encounter, and the level of maintenance they receive. Typically, insulating fire bricks can endure for numerous years, commonly ranging from 10 to 20 years or even more. Nevertheless, it is crucial to acknowledge that their lifespan may be notably shortened if they are frequently exposed to extreme temperatures or thermal shock. The lifespan of insulating fire bricks can be prolonged through regular maintenance and appropriate usage. This encompasses periodic cleansing to eliminate any debris or accumulation that could impact their performance. Additionally, it is vital to avoid abrupt temperature fluctuations or excessive stress on the bricks, as this can result in cracking or damage. In conclusion, the longevity of insulating fire bricks can vary. However, by practicing proper care and maintenance, they can offer dependable insulation for numerous years in high-temperature scenarios.

- Q:Can insulating fire bricks be used for insulation in heat exchangers?

- Insulation in heat exchangers can be achieved by utilizing insulating fire bricks. These bricks are constructed from a lightweight refractory material that boasts exceptional thermal insulation properties. With their low thermal conductivity, insulating fire bricks effectively minimize heat transfer between the two sides of the heat exchanger. Consequently, they aid in maintaining the desired temperature within the heat exchanger and prevent heat loss to the surroundings. Furthermore, the durability of these bricks is evident as they can endure high temperatures and thermal shocks, making them ideal for the harsh conditions typically encountered in heat exchangers. In summary, incorporating insulating fire bricks into heat exchangers not only enhances energy efficiency and reduces heat loss but also improves the overall system performance.

- Q:Can insulating fire bricks be used in the construction of kilns?

- Insulating fire bricks have the ability to be utilized in the construction of kilns. With a focus on possessing a high insulating value, these bricks can endure high temperatures while minimizing heat loss. This attribute renders them well-suited for the task of kiln construction as they effectively preserve and regulate the desired temperature within the kiln. Furthermore, these bricks are lightweight and easily manageable, adding to their convenience in kiln construction. An additional advantage lies in their resistance to thermal shock, an imperative characteristic for kilns that experience swift temperature fluctuations. In general, insulating fire bricks are a favored option for kiln construction due to their insulating properties, durability, and user-friendliness.

- Q:Are insulating fire bricks suitable for insulation in power boilers?

- Insulating fire bricks can be suitable for insulation in power boilers depending on the specific requirements and conditions of the boiler. Insulating fire bricks are known for their high temperature resistance and low thermal conductivity, which makes them effective in reducing heat loss and improving energy efficiency in various applications. However, when considering their use in power boilers, several factors need to be taken into account. Firstly, the operating temperature and pressure of the boiler should be considered to ensure that the insulating fire bricks can withstand these conditions without any degradation or failure. Power boilers typically operate at high temperatures and pressures, so it is important to choose insulating fire bricks that have a high temperature rating and can withstand the required pressure. Additionally, the composition and structure of the insulating fire bricks should be considered. Some power boilers may contain corrosive or abrasive substances, which can potentially damage the insulating fire bricks over time. Therefore, it is important to select insulating fire bricks that are resistant to corrosion and abrasion, or to consider additional protective measures such as coatings or linings. Furthermore, the thermal conductivity of the insulating fire bricks should be evaluated. While insulating fire bricks have low thermal conductivity compared to other refractory materials, it is important to ensure that they provide sufficient insulation for the specific requirements of the power boiler. This may involve calculating heat transfer rates and determining the appropriate thickness and density of the insulating fire bricks to achieve the desired insulation performance. Ultimately, the suitability of insulating fire bricks for insulation in power boilers depends on careful consideration of factors such as temperature, pressure, composition, structure, and thermal conductivity. Engaging with experts and conducting proper evaluations and calculations will help determine if insulating fire bricks are a suitable choice for insulation in a particular power boiler application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light weight fire clay for insulating fire brick use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords