Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Product Advantages:

OKorder's Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

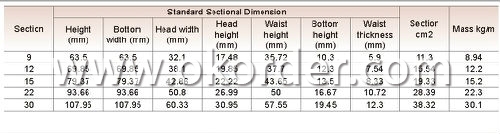

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Packaging & Delivery of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What is the normal tolerance of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20inches the Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:What is the difference between Q235B rail and 55Q rail?

- The 55Q material is mainly used for mine rail, while another is more commonly used, such as the use of no special requirements on the selection of Q235, another reason is that the price is also a cheaper one.

- Q:What are the factors considered in determining the appropriate steel rail hardness for a railway line?

- The factors considered in determining the appropriate steel rail hardness for a railway line include the type and weight of trains that will be running on the line, the speed at which the trains will be traveling, the curvature of the track, the expected traffic volume, and the environmental conditions such as temperature and humidity. Additionally, the type of ballast and subgrade strength are also taken into account.

- Q:What are the safety measures for pedestrians near railway tracks with steel rails?

- Safety measures for pedestrians near railway tracks with steel rails include: 1. Obeying warning signs and signals: Pedestrians should always adhere to warning signs, signals, and barriers indicating the presence of railway tracks. This includes obeying pedestrian crossing signals and not crossing when the barriers are down. 2. Using designated crossings: Pedestrians should only cross railway tracks at designated pedestrian crossings. These crossings are designed to provide a safe path for pedestrians and often have additional safety features such as gates, warning lights, and audible alarms. 3. Looking and listening for trains: Before crossing the tracks or walking alongside them, pedestrians should always look both ways and listen for any approaching trains. Trains can be silent and may not always be easily visible, so it is important to be vigilant. 4. Keeping a safe distance: Pedestrians should maintain a safe distance from the railway tracks and avoid walking on or along the tracks as much as possible. It is crucial to stay out of the "danger zone," which is the area approximately 15 feet on either side of the tracks. 5. Avoiding distractions: Pedestrians should refrain from using electronic devices, such as phones or headphones, that may distract them from their surroundings when near railway tracks. Being fully aware of the environment is essential for pedestrian safety. 6. Educating oneself: It is important for pedestrians to familiarize themselves with the basic rules and safety guidelines when it comes to interacting with railway tracks. This can be done through public safety campaigns, educational materials, or seeking information from local authorities or railway companies. By following these safety measures, pedestrians can significantly reduce the risk of accidents or incidents near railway tracks with steel rails.

- Q:How do steel rails contribute to railway safety?

- Steel rails contribute to railway safety in several ways. Firstly, steel rails are incredibly strong and durable. They can withstand the weight of heavy trains and provide a stable and reliable track structure. This strength helps to prevent derailments and ensures that trains can travel safely at high speeds without the risk of the rails bending or breaking under the pressure. Secondly, steel rails have a smooth and consistent surface, which allows for smooth and efficient train operation. This reduces the risk of sudden jolts or vibrations that could potentially cause accidents or damage to the train or tracks. The smooth surface also ensures that the wheels of the train can maintain proper contact with the rails, preventing any loss of traction or slipping. Additionally, steel rails are resistant to wear and tear, even under heavy use. They are designed to withstand the constant contact and friction from the train wheels, minimizing the formation of defects or imperfections on the surface. This reduces the risk of any irregularities that could potentially cause accidents or disrupt train operations. Furthermore, steel rails have excellent heat resistance properties. They can withstand the extreme temperatures generated by the friction between the train wheels and the rails. This is particularly important in areas with high-speed trains or heavy traffic, as excessive heat can cause the rails to expand and warp, leading to track deformations or even derailments. The heat resistance of steel rails helps to ensure that the tracks remain stable and safe for train operations. Overall, steel rails play a crucial role in maintaining railway safety. Their strength, durability, smoothness, resistance to wear and tear, and heat resistance properties all contribute to the safe and efficient operation of trains, reducing the risk of accidents and ensuring the smooth flow of rail traffic.

- Q:How are steel rails protected against chemical spills or leaks?

- Steel rails are protected against chemical spills or leaks through the application of protective coatings or liners. These coatings act as a barrier, preventing the chemicals from directly contacting the steel and causing corrosion. Additionally, regular inspections and maintenance procedures are carried out to promptly identify and address any potential spills or leaks to minimize their impact on the steel rails.

- Q:What are the specifications for steel rails used in high-speed rail networks?

- The specifications for steel rails used in high-speed rail networks typically include stringent requirements for material composition, strength, and durability. These rails are typically made of high-quality steel alloys that are designed to withstand high levels of stress, fatigue, and wear. They are often required to meet specific dimensional tolerances and have a smooth surface finish to ensure efficient and safe operation at high speeds. Additionally, the rails must adhere to strict standards for straightness, alignment, and flatness to ensure smooth and stable train movements.

- Q:What are the design considerations for steel rails in high-speed rail systems?

- Some of the key design considerations for steel rails in high-speed rail systems include factors such as track alignment, rail profile and geometry, material selection, rail fastening systems, and maintenance and safety requirements. The track alignment needs to be designed to minimize curves and gradients to allow for smoother and faster train operations. Rail profile and geometry play a crucial role in ensuring stability, reducing wear and tear, and minimizing noise and vibrations. Material selection is important to ensure high strength, durability, and resistance to fatigue and corrosion. Rail fastening systems must provide reliable and secure attachment to the track structure while allowing for expansion and contraction. Lastly, regular maintenance and safety considerations are necessary to ensure the integrity of the tracks and to prevent accidents or failures that could compromise the safety and efficiency of the high-speed rail system.

- Q:How do steel rails handle changes in train direction?

- Steel rails are designed to handle changes in train direction by providing a smooth and stable track surface. The rails are securely fastened to sleepers or ties, which are embedded in the ground, ensuring that they can withstand the lateral forces exerted by the train during turns. Additionally, the shape of the rails, known as the rail profile, allows for easy transition between different directions by providing a consistent surface for the train wheels to roll on. Overall, steel rails provide the necessary support and stability to enable trains to navigate changes in direction safely and efficiently.

- Q:Can steel rails be used for inclined or steep gradient tracks?

- Yes, steel rails can be used for inclined or steep gradient tracks. Steel rails are known for their strength and durability, making them suitable for various track gradients. However, additional measures such as proper track design, maintenance, and safety precautions may be necessary to ensure safe and efficient operation on inclined or steep gradient tracks.

- Q:How are steel rails tested for quality assurance?

- Steel rails are tested for quality assurance through a variety of methods including visual inspections, ultrasonic testing, magnetic particle testing, and hardness testing. These tests ensure that the steel rails meet the required specifications and standards for strength, durability, and safety in railway applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords