Light Steel Frame Formwork for Lower Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. CMAX Light Steel Frame Formwork Description

CMAX Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of Light Steel Frame Formwork

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

- We can special design according to any requirements.

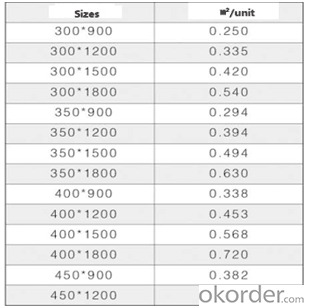

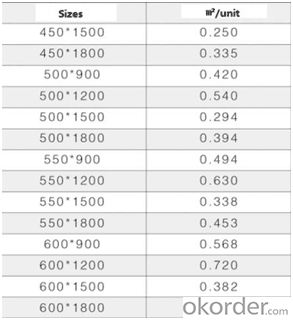

3. Light Steel Frame Formwork Specifications

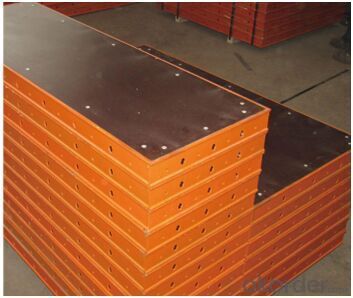

4. Light Steel Frame Formwork Images

5. FAQ of Light Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:How does steel frame formwork handle different types of formwork joint arrangements?

- Steel frame formwork is a versatile and robust system that can handle different types of formwork joint arrangements with ease. This type of formwork is designed to be adjustable and flexible, allowing for various configurations and combinations of joints. One common type of formwork joint arrangement is the butt joint, where two formwork panels meet end-to-end. Steel frame formwork is designed with special connectors and clamps that securely hold the panels together, ensuring a tight and seamless joint. These connectors are adjustable, allowing for precise alignment of the panels to achieve the desired formwork shape and dimensions. Another type of joint arrangement is the corner joint, where two formwork panels meet at a 90-degree angle. Steel frame formwork is equipped with corner connectors that securely hold the panels together at the desired angle. These connectors are adjustable as well, allowing for precise alignment and ensuring a strong and stable corner joint. In addition to butt and corner joints, steel frame formwork can also handle other types of joint arrangements such as T-joints, cross joints, and Y-joints. The adjustable connectors and clamps of steel frame formwork enable easy assembly and disassembly of the panels, making it possible to create various joint configurations as required by the specific formwork design. Furthermore, steel frame formwork provides excellent stability and load-bearing capacity, making it suitable for handling different types of joint arrangements even in complex and demanding construction projects. The steel frames and panels are designed to withstand the pressure and forces exerted during the concrete pouring and curing process, ensuring the integrity and strength of the formwork joints. Overall, steel frame formwork is a reliable and efficient system that can handle different types of formwork joint arrangements. Its adjustable connectors and clamps, along with its stability and load-bearing capacity, make it a preferred choice for various construction applications.

- Q:How does steel frame formwork support vertical loads?

- Steel frame formwork supports vertical loads by providing a strong and rigid structure that can resist the weight and pressure exerted by the concrete and any other materials used in construction. The steel frames are designed to distribute the load evenly and efficiently, ensuring stability and preventing any deformation or collapse during the pouring and curing of the concrete.

- Q:How does steel frame formwork contribute to better concrete compaction in congested areas?

- Steel frame formwork contributes to better concrete compaction in congested areas by providing a rigid structure that holds the concrete in place during the pouring and curing process. This formwork system allows for precise placement of the concrete, ensuring that it is evenly distributed and compacted without any gaps or voids. Additionally, the steel frame formwork allows for easy access to the concrete for vibrators and other compaction equipment, enabling efficient compaction even in tight spaces. Overall, the use of steel frame formwork promotes better concrete compaction in congested areas, resulting in a higher quality and more durable concrete structure.

- Q:What are the different types of concrete curing methods used with steel frame formwork?

- Different concrete curing methods can be used with steel frame formwork to ensure proper hydration and strength development of the concrete, as well as prevent cracking and defects. Some commonly used methods include: 1. Water curing: This traditional method involves continuously moistening the concrete surface with water. It can be done by spraying water directly onto the surface or by covering it with wet burlap or plastic sheets. 2. Membrane curing: Impermeable membranes or curing compounds are applied to the concrete surface to retain moisture and promote hydration. These membranes, made of plastic, wax, or other materials, are usually sprayed or brushed onto the surface. 3. Steam curing: High-pressure steam is used to accelerate the hydration process and achieve faster strength development. This method is commonly used in precast concrete applications where time is crucial. 4. Chemical curing: Chemical compounds like calcium chloride or sodium silicate can be added to the concrete mix to speed up the curing process. These compounds react with the cement to promote hydration and reduce overall curing time. 5. Insulation curing: The concrete surface is covered with insulating materials such as blankets or foam boards to retain heat and moisture. This method is often employed in cold weather conditions to prevent freezing and maintain optimal curing temperature. 6. Carbonation curing: Carbon dioxide (CO2) is used to cure the concrete by injecting it into the mix or applying it to the surface. This triggers a chemical reaction and promotes the formation of calcium carbonate. Carbonation curing is environmentally friendly as it reduces the carbon footprint associated with traditional cement production. It is important to consider project requirements, weather conditions, and time constraints when selecting the appropriate concrete curing method for a steel frame formwork project. Consulting with a structural engineer or concrete specialist is recommended to determine the most suitable method.

- Q:How does steel frame formwork affect the overall structural integrity of a building?

- Steel frame formwork can greatly enhance the overall structural integrity of a building. Its robust construction and high strength properties provide excellent support and stability during the concrete pouring process, ensuring that the structure remains strong and resilient. The steel frame formwork system also offers precise alignment and accurate dimensions, resulting in a more even distribution of loads across the building. This ultimately contributes to the durability and long-term stability of the structure, making it a reliable and efficient choice for construction projects.

- Q:What are the considerations for selecting the appropriate formwork for different concrete finishes?

- Several factors need to be taken into account when choosing the right formwork for different concrete finishes. Firstly, it is important to clearly define the desired concrete finish. There are several options available, including smooth, textured, exposed aggregate, or architectural finishes. Each of these finishes requires specific formwork to achieve the desired result. For instance, smooth finishes may require high-quality plywood or steel panels for a seamless appearance, while textured finishes may necessitate form liners or specialized textured panels. Secondly, the complexity of the formwork design should be considered. If the concrete finish requires intricate patterns or unique shapes, the formwork should be flexible enough to accommodate these design elements. This may involve using adjustable formwork systems or custom-made formwork. The durability of the formwork is another crucial factor to consider. Concrete exerts significant pressure on the formwork during pouring and curing, so it must be strong enough to withstand these forces. Additionally, the formwork should be resistant to moisture and chemicals present in the concrete mix. Opting for formwork made from materials like steel or high-quality plywood ensures durability and longevity. Ease of assembly and disassembly is also worth considering. Efficient formwork systems that are quick and easy to install and dismantle can save time and labor costs. Some formwork systems come with interlocking components or adjustable features, making them quicker and easier to work with. Cost is an important consideration when selecting formwork. The formwork should provide value for money while meeting the desired finish requirements. Comparing the costs of different formwork options, including rental and purchase options, can help determine the most cost-effective solution. Lastly, safety considerations should never be overlooked. The formwork should be designed and installed in a way that ensures the safety of workers during the construction process. This may involve using formwork with built-in safety features or incorporating additional safety measures, such as guardrails or working platforms. In conclusion, selecting the appropriate formwork for different concrete finishes requires careful consideration of factors such as the desired finish, complexity of the design, durability, ease of assembly, cost, and safety. By taking these factors into account, one can choose the most suitable formwork system to efficiently and effectively achieve the desired concrete finish.

- Q:What are the different methods of bracing steel frame formwork?

- Construction projects commonly utilize various methods to brace steel frame formwork. These techniques encompass: 1. Diagonal bracing: To reinforce steel frame formwork, diagonal bracing is frequently employed. It entails the installation of diagonal members at different angles to enhance stability and withstand lateral forces. These members can be constructed from steel, timber, or aluminum. 2. Cross bracing: Stability and resistance against horizontal forces are achieved through cross bracing. This method involves the installation of intersecting horizontal and vertical members forming an X shape. Typically, cross braces are composed of steel or other high load-bearing materials. 3. Tension bracing: In structures with significant tension forces, tension bracing is commonly utilized. This technique involves the installation of cables or rods under tension to provide stability and resist lateral forces. High-strength steel or materials with high tensile strength are often used for tension braces. 4. Shear bracing: Shear bracing is employed to counteract shear forces. Members capable of resisting shear forces are typically installed diagonally or horizontally and are constructed from steel or other shear-resistant materials. 5. Moment bracing: Moment bracing ensures stability and resistance against moment forces. These braces are typically placed at the corners or edges of the steel frame formwork to withstand bending or twisting forces. Usually, moment braces are made from steel or other structurally robust materials. In conclusion, the selection of a bracing method relies on specific project requirements, including structure height and size, expected loads and forces, and material choices. Consulting with structural engineers and adhering to building codes and regulations is vital to ensure the safety and stability of the steel frame formwork during the selection and installation of bracing methods.

- Q:Can steel frame formwork be used for the construction of residential buildings?

- Yes, steel frame formwork can be used for the construction of residential buildings. Steel frame formwork is a versatile and durable system that offers several advantages over traditional formwork methods. Firstly, steel frame formwork provides a higher level of precision and accuracy in construction. The steel frames are designed to be rigid and stable, ensuring that the concrete is poured and set in the desired shape and dimensions. This results in a more consistent and uniform finish, which is especially important in the construction of residential buildings where aesthetics play a crucial role. Additionally, steel frame formwork is highly reusable, making it a cost-effective solution for residential construction projects. The frames can be easily dismantled and reassembled for use in subsequent projects, reducing the need for new formwork materials and minimizing waste. This not only saves money but also promotes sustainability in construction practices. Furthermore, steel frame formwork offers faster construction times compared to traditional formwork methods. The modular design of the frames allows for quick and efficient assembly, resulting in reduced construction schedules. This is particularly advantageous in residential construction where time is of the essence, as it allows homeowners to move into their new homes sooner. Lastly, steel frame formwork provides enhanced safety during construction. The rigid steel frames offer stability and support, reducing the risk of accidents and ensuring the safety of workers on the construction site. In conclusion, steel frame formwork is a suitable and effective method for the construction of residential buildings. Its precision, reusability, speed, and safety benefits make it an ideal choice for developers and builders looking to deliver high-quality residential projects efficiently.

- Q:Are there any specific design considerations when using steel frame formwork?

- Yes, there are several specific design considerations when using steel frame formwork in construction projects. Firstly, the strength and stability of the steel frame formwork system need to be carefully assessed and designed to ensure that it can withstand the loads imposed during concrete pouring and curing. This includes considering factors such as the weight of the concrete, wind loads, and any additional loads from construction equipment or workers. Secondly, the dimensions and layout of the steel frame formwork should be designed to accommodate the desired shape and size of the concrete structure. This may involve incorporating adjustable panels or modular components to allow for flexibility and ease of assembly. Thirdly, the connections between the steel frame formwork components need to be carefully designed to ensure proper alignment and stability. This may include using high-quality fasteners and ensuring that the connections are adequately braced to prevent any movement or deformation during the concrete pouring process. Additionally, considerations should be given to the surface finish requirements of the concrete structure. Steel frame formwork may leave imprints or marks on the concrete surface, so appropriate measures should be taken to minimize any undesirable effects, such as using plywood or plastic lining on the contact surfaces. Lastly, safety is a crucial consideration when using steel frame formwork. The design should incorporate appropriate safety features, such as guardrails, handrails, and access platforms, to ensure the safety of workers during the construction process. Overall, the design of steel frame formwork should take into account structural strength, dimensional requirements, connections, surface finish, and safety to ensure a successful and efficient construction process.

- Q:What are the safety measures that need to be taken while using steel frame formwork?

- When using steel frame formwork, there are several important safety measures that need to be taken to ensure the well-being of workers and the overall success of the construction project. These safety measures include: 1. Proper training and supervision: Workers should receive adequate training on the correct usage of steel frame formwork, including how to assemble, dismantle, and handle the equipment safely. They should also be supervised by experienced personnel to prevent any potential accidents. 2. Inspection and maintenance: Regular inspection of the steel frame formwork should be conducted to identify any defects, damages, or wear and tear. Any faulty or damaged components should be immediately replaced or repaired. Maintenance should also be carried out to keep the equipment in optimal condition. 3. Personal protective equipment (PPE): Workers should be equipped with appropriate PPE, such as safety helmets, safety goggles, gloves, and steel-toe boots, to protect themselves from potential hazards, such as falling objects or injuries during assembly and dismantling. 4. Secure footing and fall protection: Workers should have a secure footing when working on steel frame formwork structures. Proper scaffolding or platforms should be provided, and guardrails should be installed to prevent falls from heights. Additionally, safety harnesses and lanyards should be used when working at elevated levels. 5. Proper lifting techniques: Workers should be trained on proper lifting techniques to prevent strains or other musculoskeletal injuries when handling heavy components of the steel frame formwork. Mechanical aids, such as cranes or hoists, should be used whenever possible to minimize manual lifting. 6. Adequate lighting and ventilation: The work area should be well-lit to ensure good visibility, and proper ventilation should be provided to prevent the accumulation of harmful fumes or gases. 7. Communication and coordination: Effective communication and coordination between workers and supervisors are essential to ensure smooth operations and avoid accidents. Clear instructions, signals, and warning signs should be used to alert workers of any potential hazards or changes in the work environment. By following these safety measures, the risk of accidents and injuries can be greatly minimized when using steel frame formwork, creating a safer working environment for all involved.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Frame Formwork for Lower Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products