Light Industrial Healthy PVC/PU/PE Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Industrial Healthy PVC/PU/PE Conveyor Belt

PVC Conveyor Belt

PVC conveyor belt has good elasticity ,not easy to be deformed . It is widely used in good , tobacco , logistics , packaging and other industries . Applicable to coal mine underground transportation ,also can be used in metallurgy ,chemical idustry material handling .

Applications & features:

It is widely used in the assembly lines in the areas of food processing, pharmaceutical, electronics, cigarette, printing

Product features: hard wearing, good tensile strength, long service life.

Product specification: One fabric- One rubberized, Two fabric- Two rubberized, Three fabric- three rubberized,ect

Forms of joints: tooth-shaped, stepped&angled, or metal buckle

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

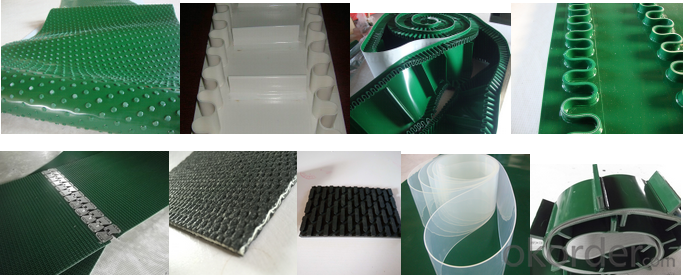

Product photos:

Pls contact me freely if any inquiry,thank you!

- Q:How do olive nets impact the overall health of the olive tree?

- Olive nets can positively impact the overall health of olive trees by protecting the fruits from various pests and birds. These nets act as a barrier, preventing damage caused by insects, birds, and other animals, which can lead to reduced crop yield and compromised tree health. Additionally, olive nets also shield the tree's fruits from excessive exposure to sunlight, helping to prevent sunburn and maintain their quality.

- Q:How do olive nets affect the growth and health of olive trees?

- Olive nets can positively affect the growth and health of olive trees by providing protection against pests and extreme weather conditions. These nets act as a barrier, preventing insects and birds from damaging the fruit and foliage, which can lead to reduced yield and overall tree health. Additionally, olive nets can shield the trees from excessive sunlight, wind, and hail, helping to maintain optimal growing conditions. Ultimately, the use of olive nets can contribute to the overall productivity and well-being of olive trees.

- Q:Are there any alternative methods to using olive nets?

- Yes, there are alternative methods to using olive nets. Some farmers use mechanical harvesters or shakers to harvest olives, especially in large-scale commercial operations. Another method is handpicking, where workers carefully pick the olives from the trees. Additionally, some farmers employ a combination of methods, such as using nets only for certain trees or using a combination of handpicking and mechanical harvesting.

- Q:Can olive nets be used for both rain-fed and irrigated olive orchards?

- Yes, olive nets can be used for both rain-fed and irrigated olive orchards. Olive nets are primarily used to protect the olives from birds, pests, and debris, regardless of the irrigation method. They provide a physical barrier to prevent damage to the crop and are suitable for use in both rain-fed and irrigated orchards.

- Q:How do olive nets affect the overall antioxidant content of the olives?

- Olive nets have no direct impact on the overall antioxidant content of olives. The antioxidant content of olives is primarily determined by factors such as olive variety, growing conditions, and processing methods. Olive nets are mainly used to protect the olives from pests and birds during the ripening period, ensuring a higher yield and quality of olives, but they do not affect the antioxidant levels.

- Q:White plastic for a long time. Why does it turn yellow?

- There are plastic products called plasticizers of raw materials, mainly plays the role of anti-aging, but it will be volatile in the air, so when increased when plasticizer reduced, the color will also fade, the elastic plastic shriveled, becomes very brittle, it will turn yellow.

- Q:Do olive nets affect the quality or taste of the olives?

- Yes, olive nets can affect the quality and taste of the olives. The nets protect the olives from pests and falling on the ground, minimizing damage. However, if the olives remain on the tree for an extended period, they may become overripe and lose some of their flavor. Additionally, the nets can create a microclimate that affects the maturation process, potentially altering the taste of the olives. Therefore, while olive nets offer protection, their use should be carefully managed to ensure optimal quality and taste.

- Q:How can plastics be broken down into harmless substances?

- As a new type of plastic material products present situation and harm of white pollution, has the advantages of light weight, waterproof, durable, sophisticated production technology and low cost, is widely used and has increased year by year in the world. The growth rate of plastic packaging materials in the world market is higher than that of other packaging materials, and the average annual growth rate of plastic packaging materials in 1990-1995 years is 8.9%. China is one of the ten largest producers and consumers of plastic products in the world.

- Q:How does an olive net help in reducing the damage to olives during harvesting?

- An olive net is designed to be spread under the olive trees during harvesting. It helps in reducing the damage to olives by providing a protective layer that catches the falling olives, preventing them from hitting the ground and getting bruised or damaged. The net also makes it easier to collect the olives, as they can be gathered directly from the net without the risk of stepping on them or causing further harm. Overall, the olive net ensures a more efficient and gentle harvesting process, minimizing the potential damage to the olives.

- Q:Can olive nets be used in windy areas?

- Yes, olive nets can be used in windy areas. However, it is important to ensure that the nets are properly secured to prevent them from being blown away or damaged by strong winds. Additionally, using heavier or reinforced nets can provide better protection in windy conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Industrial Healthy PVC/PU/PE Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords