Light Duty PVC Conveyor Belt Polyurethane/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty PVC Conveyor Belt Polyurethane/PU Conveyor Belt

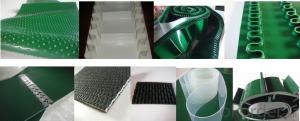

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q:Is it harmful to health to drink water with plastic cups?

- Plastic cups are also prone to bacteria.Cup by the computer, chassis and other static impact, will absorb more dust, bacteria, bacteria, long time will affect health. Experts suggest that the best cup with a cover, and do not close to the computer and other appliances, usually should keep the indoor air circulation, ventilation window, let dust go with the wind.

- Q:How do you prevent olive nets from sagging or drooping?

- One way to prevent olive nets from sagging or drooping is by using proper tensioning techniques. Ensuring that the nets are tightly stretched and secured at the edges and corners can help maintain their shape and prevent sagging. Additionally, regularly checking and adjusting the tension of the nets as needed can also help prevent sagging over time.

- Q:How does an olive net affect the overall appearance of the olive grove?

- An olive net can significantly impact the overall appearance of an olive grove. When properly installed, it creates a uniform and tidy look by covering the entire grove, concealing the tree branches and reducing the visibility of fallen leaves. The net's color, typically a vibrant green, blends in with the foliage and enhances the visual appeal of the grove. Additionally, the net's presence indicates the active harvesting season, adding a sense of liveliness and productivity to the overall appearance of the olive grove.

- Q:What is the pungent smell of plastic products?

- Materials are many. They may be polyethylene, polypropylene, polyvinyl chloride, and so long as they are insoluble in water, they can be used as hoses. Some polymer itself has a flavor, but it should not be pungent, but also may be that I said before impurities. I can't give a positive answer. But one thing is for sure, the impurities in polymer materials are almost impossible to remove

- Q:Are olive nets resistant to weather conditions?

- Yes, olive nets are designed to be resistant to various weather conditions. They are typically made of durable and weatherproof materials that can withstand exposure to sunlight, rain, wind, and other environmental elements. This allows olive nets to provide effective protection for olive trees and fruits during different weather conditions.

- Q:Are there any safety precautions to consider when using olive nets?

- Yes, there are several safety precautions to consider when using olive nets. Firstly, it is important to ensure that the nets are properly secured and evenly spread out to avoid any sagging or falling. This can be achieved by using sturdy poles and tying the nets tightly. Additionally, it is crucial to regularly inspect the nets for any tears or damages that may compromise their effectiveness and replace them if needed. When working with olive nets, it is recommended to wear protective gloves to prevent injury from sharp branches or thorns. Lastly, it is essential to practice caution while working on elevated surfaces or using ladders to avoid falls or accidents.

- Q:Are olive nets easy to clean and maintain?

- Yes, olive nets are generally easy to clean and maintain. They can be easily washed with water or a mild soap solution to remove any dirt, debris, or olive residue. Additionally, regular maintenance, such as inspecting for any tears or damages, can help ensure their longevity.

- Q:How do you prevent olive nets from causing damage to surrounding vegetation or wildlife?

- To prevent olive nets from causing damage to surrounding vegetation or wildlife, there are a few measures that can be taken. Firstly, it is important to properly install and secure the nets to ensure that they do not come loose or get blown away by strong winds. Additionally, regular monitoring and maintenance of the nets should be done to address any potential issues or damage caused by the nets. It is also crucial to remove the nets promptly after the harvest season to minimize any negative impact on vegetation or wildlife. Finally, using alternative methods like manual harvesting or employing specialized machinery can also help reduce the potential damage caused by olive nets.

- Q:What are the grades of plastics from 1 to 7?

- The United States Plastics Industry Association (Society of Plastics Industry, SPI) made use of plastic products of plastic type sign code, is composed of representatives of the circular triangle in the middle of the three arrows mark, plus the numbers, they will recover triangle marking attached to the plastic products, and with the numbers 1 to 7 and English abbreviations to refer to the use of plastic resin type generation. As a result, the identification of plastic varieties has become simple and easy, and the cost of recycling has been substantially reduced. Today, many countries in the world have adopted the SPI logo scheme. China enacted almost identical labeling standards in 1996.

- Q:How do olive nets impact the overall aroma of the olives?

- Olive nets have a minimal impact on the overall aroma of olives. These nets are primarily used to collect olives during harvesting, preventing them from falling to the ground and being contaminated. The nets do not significantly alter or influence the aroma of the olives themselves. The aroma is mainly determined by factors such as olive variety, maturity, and processing techniques.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Duty PVC Conveyor Belt Polyurethane/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords