Light Duty PVC Conveyor Belt for Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ight Duty PVC Conveyor Belt for Food Processing Industry

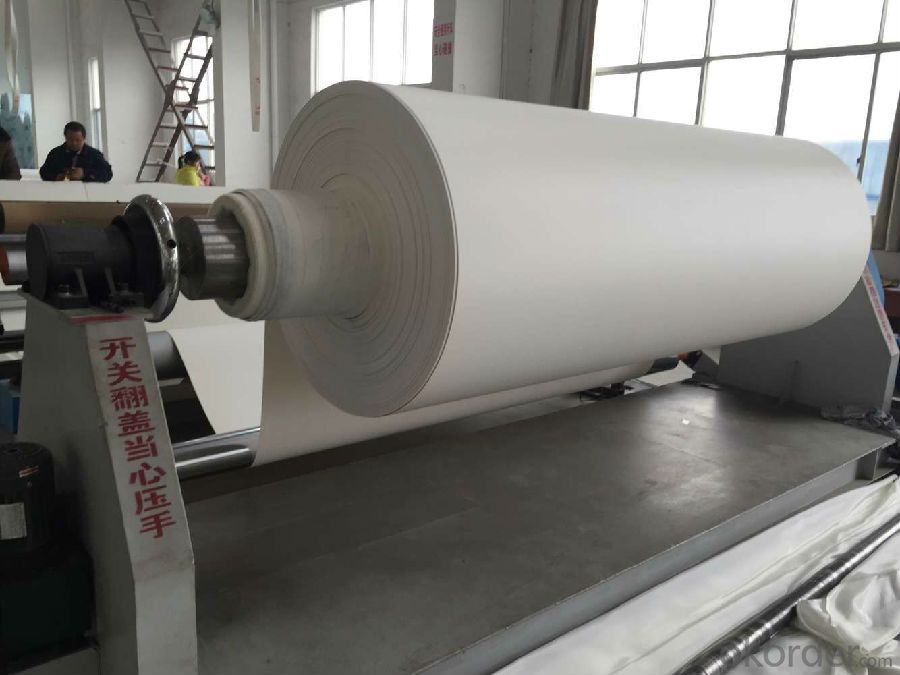

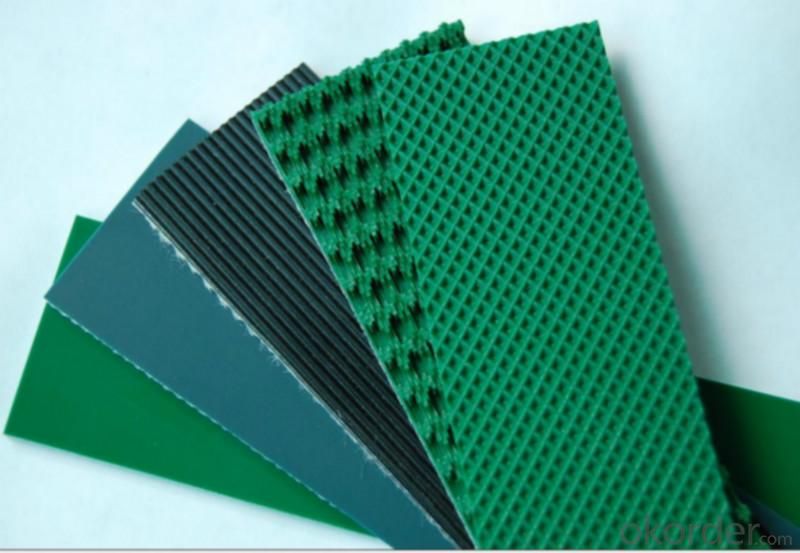

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

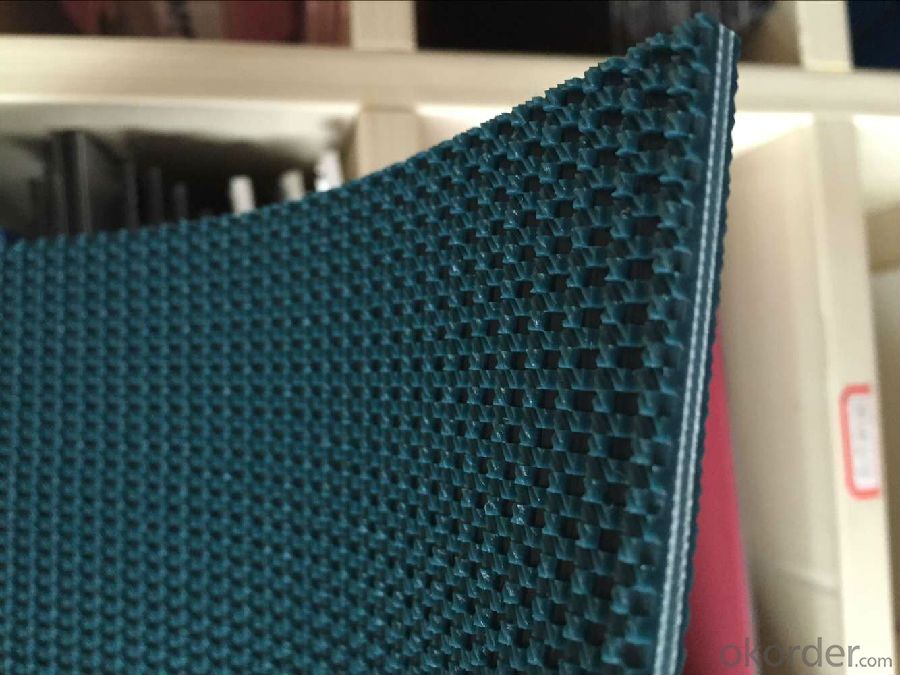

The main products include flat surface series, anti-slid series which diversified in a lot of textures for meeting different conveying conditions and environment, featuring anti-static, anti-corrosion, flame retardant etc.

There are wide range of patterns of rough top belt available including Diamond, Chevron, Herringbone, Rib, Grid, Wave, Round and Oval nubs, Convex-tooth etc.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Product Photos

For more informations,please contact us freely,thank you.

- Q:Can olive nets be used to protect against wind damage?

- No, olive nets are primarily used to protect olive trees from birds, not wind damage.

- Q:How do olive nets affect the growth and health of olive trees?

- Olive nets positively affect the growth and health of olive trees by providing protection against pests and adverse weather conditions. These nets act as a physical barrier, preventing insects, birds, and other animals from damaging the trees or feeding on the fruits. Additionally, they shield the trees from extreme temperatures, strong winds, and heavy rain, ultimately reducing the risk of diseases and promoting overall tree vitality.

- Q:Can olive nets be used to reduce soil erosion?

- Yes, olive nets can be used to reduce soil erosion. Olive nets are often used in olive orchards to catch fallen olives during harvest, but they also serve as an effective method to prevent soil erosion. These nets act as a physical barrier, preventing soil particles from being washed away by rainwater or blown away by wind. By keeping the soil in place, olive nets help maintain soil fertility, prevent loss of topsoil, and promote healthy plant growth.

- Q:Are olive nets reusable?

- Yes, olive nets are generally reusable. They can be used multiple times for harvesting olives, as long as they are properly maintained and stored.

- Q:Can plastic bottles be recycled?

- There may be some harmful substances dissolved, 1 representative PET polyethylene terephthalate) general mineral water, carbonated drinks and functional drinks bottles are using this material to do a high temperature easy to deformation. In hot weather, do not put mineral water in the open air or in the car, and do not directly pour the water into the coke bottle. It can be used to make bottles, plastic bottles for space cups, and other manufacturers of plastic bottles 7. Try not to use boiling water.

- Q:Can olive nets be used for olive tree nurseries?

- Yes, olive nets can be used for olive tree nurseries. Olive nets are specifically designed to protect olive trees from pests, birds, and extreme weather conditions. They can help to create a controlled environment that is favorable for the growth and development of olive trees in nurseries.

- Q:Can olive nets be used in areas with high bird populations?

- Yes, olive nets can be used in areas with high bird populations to protect olive trees from bird damage. The nets act as a physical barrier, preventing birds from accessing the trees and feeding on the olives. This can help mitigate crop losses caused by bird predation and is a commonly used method in areas where bird populations are abundant.

- Q:Can olive nets be used in combination with pruning?

- Yes, olive nets can be used in combination with pruning. Pruning helps maintain the shape and health of olive trees, and using nets during the pruning process can help collect the pruned branches and leaves, making cleanup easier. Additionally, olive nets can also be used during the harvest season to catch the falling olives, ensuring that none are lost and facilitating the collection process.

- Q:Do olive nets protect against hail damage?

- No, olive nets do not provide protection against hail damage.

- Q:Can olive nets be used in regions with extreme weather conditions?

- Olive nets may not be suitable for use in regions with extreme weather conditions as they are typically designed for normal weather conditions. Extreme weather such as heavy rain, strong winds, or extreme temperatures could potentially damage or compromise the effectiveness of olive nets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Duty PVC Conveyor Belt for Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords