Lidding Foil Lidding Foils Using Aluminum Foils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

lidding foil lidding foils USING ALUMINIUM

Application: Lid of yogurt package, dairy package

Alloy: 8006/8011/8079

Temper:O

Thickness& Tolerance: 0.03mm-0.05mm(±5%)

Width& Tolerance: 200mm-1650mm(±1mm)

Mechanical Properties: Tensile Strength (U.T.S)≥50Mpa, Elongation≥1%

Standard: GB/T3198 /ASTM-B209/EN546

2.Description

Aluminium foil (or aluminum foil) is aluminium prepared in thin metal leaves with a thickness less than 0.2 millimetres (8 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used.In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such as plastics or paper to make them more useful. Aluminium foil supplanted tin foil in the mid 20th century.

Annual production of aluminium foil was approximately 800,000 tonnes (880,000 tons) in Europeand 600,000 tonnes (660,000 tons) in the U.S. in 2003.Approximately 75% of aluminium foil is used for packaging of foods, cosmetics, and chemical products, and 25% used for industrial applications (e.g. thermal insulation, cables and electronics).

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans"). Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

3.Why you can choose us?

Our quality best, service best!

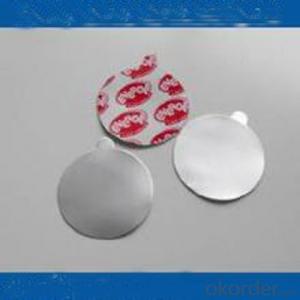

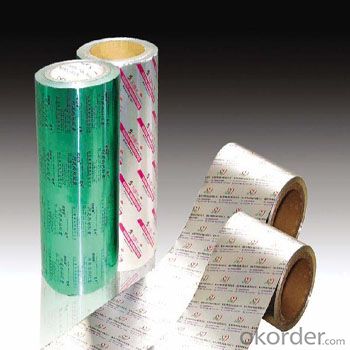

4.Pictures

5.FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

- Q:I have hamburger, Italian bread crumbs, onions, ketchupis there anything else i need? i heard if you add an egg it holds it together a little bettertrue?

- Builders do every thing to make money so if it is a tract home chances are that you could used some more insulation Go to the attic on check how deep it is and also check the net they have some great sites on this subject This kind of thing you should research the net to get the right information.

- Q:What are the advantages and disadvantages of a carbon crank over an aluminum one? Is it stiffer etc...? This is for road cycling by the way. Carbon arms that is.

- There are some very good carbon cranks out there, and there is also a lot of junk. If you have Shimano components on your road bike, their aluminum cranksets are hard to beat, light and stiff and reliable. Carbon cranks will be more expensive, and perhaps a bit lighter, but may not work as well with your components. I recently upgraded my bike with Campagnolo ultra torque carbon cranks. They are lighter and stiffer than my old square taper aluminum cranks because they are a completely different design, not because they are carbon

- Q:I'm doing a project for my exercise science course which involves building a joint in the human bodyI've chosen the hip joint.I have most of my bones' structure planned out - I'll make a wire frame out of coat hangers, then densely wrap aluminum foil around that, and coat the entire thing with plaster so that it hardensIn terms of attaching the femur, I was thinking of using a plastic ball (the kind you find in ball pits) with a strong magnet inside, and then another magnet on the pelvisThis would allow it to rotate freely without falling off, assuming the magnet is strong enough.On to ligamentsI have a general understanding of what ligaments I'm supposed to be building, but I'm not sure how to make themIn diagrams they look like they're made of chewing gum, but obviously I need something that will be suitable for a model and will stick to the bone structure.Any suggestions?Also if you have any suggestions for materials I could use for muscles, it would be greatly appreciated:]

- It won't hurt if you put them in rightRead the instructions that come with the box and use regular or smaller tampons for now especially if your flow is not very heavyYou shouldn't feel anything really.

- Q:I think it'd be a really cool idea to smoke a starburst pipe, but everyone says it's really bad for your lungsWould it still harm my lungs if I put aluminum foil in the top of the bowl and poke holes in it? So that I'm not burning the starburst, I'm only burning a little bit of foil.

- Smoking anything is bad for your lungsWhy not get high on life instead.

- Q:a)several cm of leadb)single sheet of paper c)one cm of waterd)single sheet of aluminum foil

- a) several cm of leadGamma rays are similar to X-rays but have shorter wavelengths and are more penetratingEven X-rays would pass through all but thick lead.

- Q:An aluminum foil sheet with a mass of 5 g must be compressed to a volume of how many cubic centimeters in order to sink?A container with a volume of 25 cubic cm must be filled with how many grams of gallium in order to have a density greater than one?A cylinder with a volume of 150 cubic cm must be filled with how many grams of substance in oder to float in water?thnks

- You can actually do this without calculus, since the bucket is losing sand at a constant rateThe total work will be the same as lifting the average amount of sand in the bucketThe total time this take is 80feet/2ft/s40 seconds Therefore halfway is 20 secondsAt this point the bucket weighs 600-320540 lbs Work ForceDmgD540lbs32ft/s^280ft1,382,4lbft^2/s^2

- Q:it is the 3.4 v6Mechanic friends wont look at it but are guessing that because the head gasket blew it couldve warped the heads.needing to know if just replacing the head gasket would work or what.

- Well I think pots and pans, measuring cups, cookie sheets, silicone scrappers, mixing spoons and mixing bowls are all needed in the kitchen and those are just a few that I can think of.

- Q:The only things i can use are:Popsicle sticksAluminum FoilWax PaperStrawsAnd Tape (NOOO GLUE)lt;- my teacher wont let us.

- I usually spread a little vegetable oil or olive oil in the bottom of the roasting panThat keeps the bottom of the turkey from sticking to the pan, and it also gives you the beginning of the fat you can use to make your gravy afterwardsI don't know how much to tell you to use because I don't know the size of your panMaybe 1/4 cup? Then you can always add a few Tbsp of water as the turkey cooks, and then baste the turkey with the water/oil mixtureThat will help keep the turkey moist, tooI usually put a tinfoil tent over my turkey for the first half of the cooking time, so the skin doesn't get so darkThat helps moisten the turkey, too.

- Q:do you think this is an appropriate project idea for the science fair project i have to do for physics?whether color affects the absorption or loss of heat ?i dont know whether its ok or not do u think a physics teacher would approve or is it like below level? have any ideas to make it more advanced? im not great in the science area

- $50 and under try a cheaper brand, there is no way you could ever get a GHD for $50, its the brand of the hairstraightner not the type (although its better than practically any other) if you didnt knowI suggest saving your money up for a hairstraightner and paying ATLEAST $150 to get a decent one3

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lidding Foil Lidding Foils Using Aluminum Foils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords