Lidding Foil Lid of Yoghourt Using Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminium foil (or aluminum foil) is aluminium prepared in thin metal leaves with a thickness less than 0.2 millimetres (8 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used.In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). Thefoil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimeslaminated to other materials such as plastics or paper to make them more useful. Aluminium foil supplantedtin foil in the mid 20th century.

Annual production of aluminium foil was approximately 800,000 tonnes (880,000 tons) in Europe and 600,000 tonnes (660,000 tons) in the U.S. in 2003. Approximately 75% of aluminium foil is used for packaging offoods, cosmetics, and chemical products, and 25% used for industrial applications (e.g. thermal insulation, cables and electronics).

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans").Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

2.Why you must choose us?

We can supply any help that you need!

3.Specification and application

lidding foil lidding foils USING ALUMINIUM

Application: Lid of yogurt package, dairy package

Alloy: 8006/8011/8079

Temper:O

Thickness& Tolerance: 0.03mm-0.05mm(±5%)

Width& Tolerance: 200mm-1650mm(±1mm)

Mechanical Properties: Tensile Strength (U.T.S)≥50Mpa, Elongation≥1%

Standard: GB/T3198 /ASTM-B209/EN546

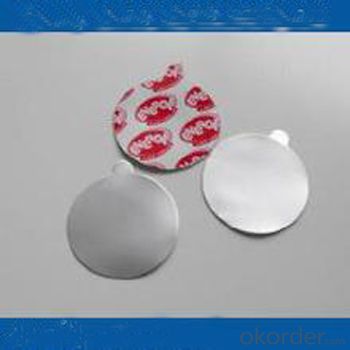

4.Pictures

5.FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

- Q:Why is aluminium so easy to make into alloys?

- Its structure is idyllic because of its arrangement of atomsThey are in a regular structure so they have a low melting point and can be shaped easily.

- Q:I live in California and I have a lot of paper to recycle, how much do they pay?

- as properly to rpm92's answer, will ought to element in the undeniable fact that your bottle isn't empty, yet consists of some quantity of non-compressible liquid which will make the quantity mandatory to burst the bottle below predictedalthough returned because of the fact that some quantity of gasoline will dissolve in the liquid, a calculation factoring that in the time of could then be too little to blow up.

- Q:I need to feed 20 people for my French class and I don't have enough ramekins and I can't buy more because my mom doesn't want to waste a bunch of money.SO I was wondering if anyone knew of a recipe for creme brulee that I could use in a huge round dish or in a huge rectangular dish.PLEASE PLEASE PLEASE PLEASE HELP.I need this by tomorrow.Thank you.

- try multiplying the ingredients of an existing recipe.

- Q:An ion of aluminum with a 3+ charge has how many protons and electrons?

- Atomic number 13 atom has equal protons and electons +3 charge means 3 electrons have been lost 13P 10E

- Q:how do u do determineee it?can u please give me those for these elements:rubidiumcalciumaluminumoxygenironmercuryand leadpleaseeeee help!and please if u can,gimme a good website i can practice on

- You determine these elements by looking at the periodic table of elements1Rubidium - Rb - 37 37 protons and electrons Atomic Mass - Atomic Number Neutrons - 85g - 37 48 Charge: + 1 2Calcium - Ca - 20 20 protons and electrons 20 neutrons Mass: 20 g Charge: + 2 3Aluminum - Al - 13 13 protons and electrons 14 neutrons Mass: 27 g Charge: + 3 4Oxygen - O - 8 8 protons and electrons 8 neutrons Mass: 16 g Charge: - 2 5Iron - Fe - 26 26 protons and electrons 30 neutrons Mass: 56 g Charge: + 2, + 3 6Mercury - Hg - 80 80 protons and electrons 121 neutrons Mass: 201 g Charge: + 1, + 2 7Lead - Pb - 82 82 protons and electrons 125 neutrons Mass: 207 g Charge: + 2, + 4

- Q:Is it aluminum or could it be something else with electrons taken out, so like carbon +1.

- Assuming it's an atom, aluminiumAlso, it says element in your question, so definitely aluminium.

- Q:I need to know what type of paper bags to use to make luminariesWe are doing this for VBSThe kids will be using a paper punch to make their designs.

- There is no wayatleast not that I can think of in a non-toxic mannerWater would break down the bagThe only thing I can think of is to make sure your candle is directly away from the paper and to line the inside of the bag with a liberal amount of aluminum foil.

- Q:So my uncle is retireing from a construction site and gave me all this copperBut I don't know what I'm able to sell, for example I could sell copper wire, also blah, and blah, and blahSo yea the point is, what scrap metal can be sold? I don't want the price, I just want to know what could be soldDo pipes count as copper? I know its gold, titanioum, aluminum etcBut I mean like what could it be? I can't go and sell aluminum paperPipes, wires, jewelery, that type of stuffPlease make a list of sevral thingsThank you!

- Basically any scrap metal can be sold, but the most common ones are copper, aluminum, and brassMost yards won't deal with titanium, you'll have to find one that specializes in that if you have any (since its construction debris, I doubt it)Yes, copper water pipes are good scrap.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lidding Foil Lid of Yoghourt Using Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords