LDPE Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LDPE Geomembranes

Products Description

This product is extruded PE membrane formed by adding anti- oxidant, absorbent of ultraviolet and dyestuff into HDPE or LDPE or EVA and will provide an effective barrier to of liquid

water and water vapor.

Characteristics

·HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and

resistance to puncture .

·LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy

installation.

·ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

Products Specification

Name | Thickness(mm) | Width(m) |

HDPE | 0.75-2.5 | 4-8 |

LDPE | 0.2-2.5 | 4-8 |

EVA | 0.2-2.5 | 2-8 |

ECB | 1.0-2.0 | 2-8 |

Features:

1.All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels,

and transportation project in most conditions.

2.Good aging, durable performance, and wide temperature range, it can be useful over

thirty years on the condition of -60æ«60æ.

3.Anti-stab and fine friction factors.

4.Canker proof, acid and alkali proof, untoxic.

5.Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6.Convevient to install and dependable effect.

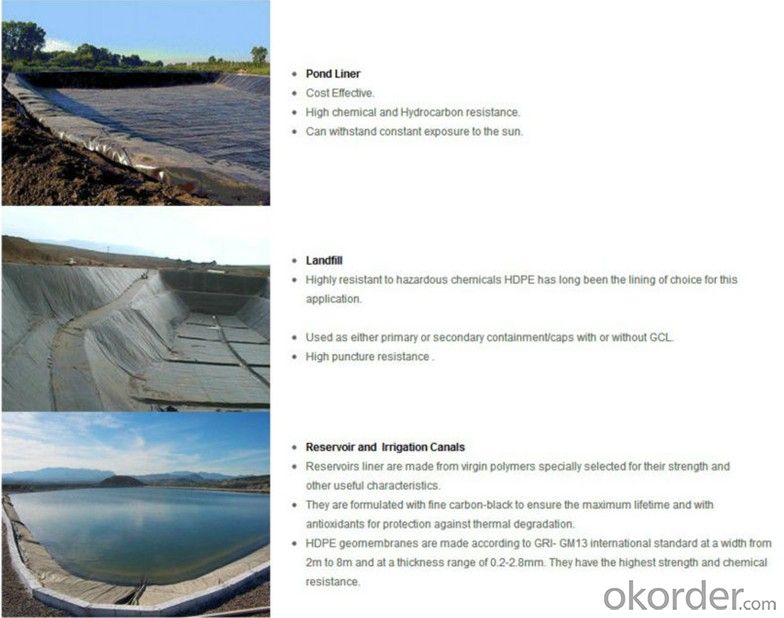

Application Rage

- Q:What is the purpose of a waterproofing membrane?

- The purpose of a waterproofing membrane is to prevent water and moisture from seeping through surfaces such as roofs, walls, or foundations, thus protecting the underlying structure from water damage and potential leaks.

- Q:Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Yes, there are several specific considerations when installing a waterproofing membrane on wood surfaces. First and foremost, it is important to ensure that the wood surface is clean, dry, and free from any dirt, dust, or debris. This will help to create a proper bond between the wood and the waterproofing membrane. Additionally, it is crucial to choose a waterproofing membrane that is specifically designed for wood surfaces. There are different types of membranes available, such as liquid-applied membranes or sheet membranes, so selecting the right one is essential. Before applying the membrane, it is advisable to prime the wood surface with a suitable primer. This will help to enhance the adhesion of the membrane and provide a more durable and long-lasting waterproofing solution. It is also important to consider the climate and weather conditions in the area where the wood surface is located. If the area is prone to extreme temperatures or heavy rainfall, it is recommended to choose a waterproofing membrane that can withstand these conditions and provide adequate protection. Furthermore, proper installation techniques should be followed to ensure the membrane is applied correctly. This may involve rolling or brushing the membrane onto the wood surface, as per the manufacturer's instructions. It is crucial to pay attention to details such as seams, corners, and edges to ensure a watertight seal. Regular maintenance and inspection are essential for the longevity of the waterproofing membrane on wood surfaces. It is important to check for any signs of damage, such as cracks or peeling, and address them promptly to prevent water infiltration and potential damage to the wood. In summary, when installing a waterproofing membrane on wood surfaces, it is crucial to prepare the surface properly, choose the right type of membrane, consider the climate and weather conditions, follow proper installation techniques, and perform regular maintenance and inspection. By doing so, you can effectively protect the wood surface from water damage and ensure its longevity.

- Q:Can a waterproofing membrane be used in conjunction with flooring materials?

- Yes, a waterproofing membrane can be used in conjunction with flooring materials. It provides an additional layer of protection, preventing water damage and seepage, which can be particularly beneficial in areas prone to moisture such as bathrooms, kitchens, or basements. By installing a waterproofing membrane beneath flooring materials, such as tiles or vinyl, it helps to maintain the integrity and longevity of the flooring while keeping the underlying structure dry.

- Q:Elastomer modified asphalt waterproofing membrane for what purpose? Need to pay attention to a few things?

- 1, storage and transportation, different types, specifications of the product should be stacked, should not be mixed. Avoid sun and rain, pay attention to ventilation. Storage temperature should not be higher than 50 ℃, put the storage, the height of not more than two layers. 2, when the ship or train transport, the membrane must be put up, stacking height of not more than two layers. To prevent the tilt or transverse pressure, if necessary, covered with felt cloth. 3, in the normal storage, transport conditions, the storage period from the date of production for one year.

- Q:Can a waterproofing membrane be used for planter boxes or green roofs?

- Yes, a waterproofing membrane can be used for planter boxes or green roofs. It helps to prevent water leakage and protect the underlying structure.

- Q:How does a waterproofing membrane handle exposure to UV rays?

- A waterproofing membrane is designed to handle exposure to UV rays by incorporating UV stabilizers and additives into its composition. These UV stabilizers work by absorbing or reflecting the harmful UV rays, preventing them from causing degradation or damage to the membrane. UV rays from the sun can be quite intense and can lead to the deterioration of various materials over time. When a waterproofing membrane is continuously exposed to UV rays, it can undergo a process called photo-oxidation, where the energy from the UV rays reacts with the membrane's molecular structure, causing it to break down and weaken. To counteract this, manufacturers add UV stabilizers to the membrane during the manufacturing process. These stabilizers act as a shield, absorbing or reflecting the UV rays and preventing them from reaching the membrane's surface. By doing so, they help to slow down the process of photo-oxidation and extend the lifespan of the waterproofing membrane. Additionally, some waterproofing membranes may also have a protective layer or coating that provides additional UV resistance. This layer acts as an extra barrier, shielding the membrane from direct exposure to UV rays and further enhancing its durability and longevity. However, it's important to note that even with UV stabilizers and protective coatings, prolonged exposure to intense UV rays can still cause some degree of degradation or discoloration over time. Therefore, it is recommended to regularly inspect and maintain the waterproofing membrane to ensure its effectiveness and address any signs of UV damage promptly.

- Q:Can a waterproofing membrane be used on tunnels with communication systems?

- Yes, a waterproofing membrane can be used on tunnels with communication systems. In fact, it is highly recommended to protect sensitive communication equipment and wiring from water damage. A waterproofing membrane is designed to create a barrier against water infiltration, preventing leaks and seepage. By applying a waterproofing membrane to the tunnel walls and floors, the communication systems can be safeguarded from potential water-related issues, such as corrosion, short circuits, and signal disruption. It is important to choose a waterproofing system that is compatible with the specific needs and requirements of the communication systems in the tunnel to ensure optimal protection and functionality.

- Q:Can a waterproofing membrane be used in boat decks or marinas?

- Yes, a waterproofing membrane can be used in boat decks or marinas. Boat decks and marinas are constantly exposed to water, making them prone to damage and deterioration over time. A waterproofing membrane can provide an effective solution to protect these surfaces from water intrusion, preventing issues such as rotting, warping, and mold growth. The membrane acts as a barrier, preventing water from seeping into the underlying structure and causing damage. It also helps to maintain the structural integrity of the boat deck or marina, prolonging its lifespan. Additionally, a waterproofing membrane can enhance the safety of these surfaces by reducing the risk of slip and fall accidents, as it can provide a slip-resistant surface. Overall, using a waterproofing membrane in boat decks or marinas is a wise choice to ensure their durability, longevity, and safety.

- Q:Can a waterproofing membrane be used for underground electrical vaults?

- Yes, a waterproofing membrane can be used for underground electrical vaults. Waterproofing membranes are commonly used to protect underground structures from water infiltration, including electrical vaults. The membrane acts as a barrier to prevent water from seeping into the vault, which can help to protect the electrical equipment and prevent damage or malfunction.

- Q:Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Yes, a waterproofing membrane is generally resistant to gasoline and other petroleum-based substances.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords