LDPE Geomembrane Liner for Landfill lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LDPE Geomembrane Introduction

LDPE Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. Its material is LDPE.

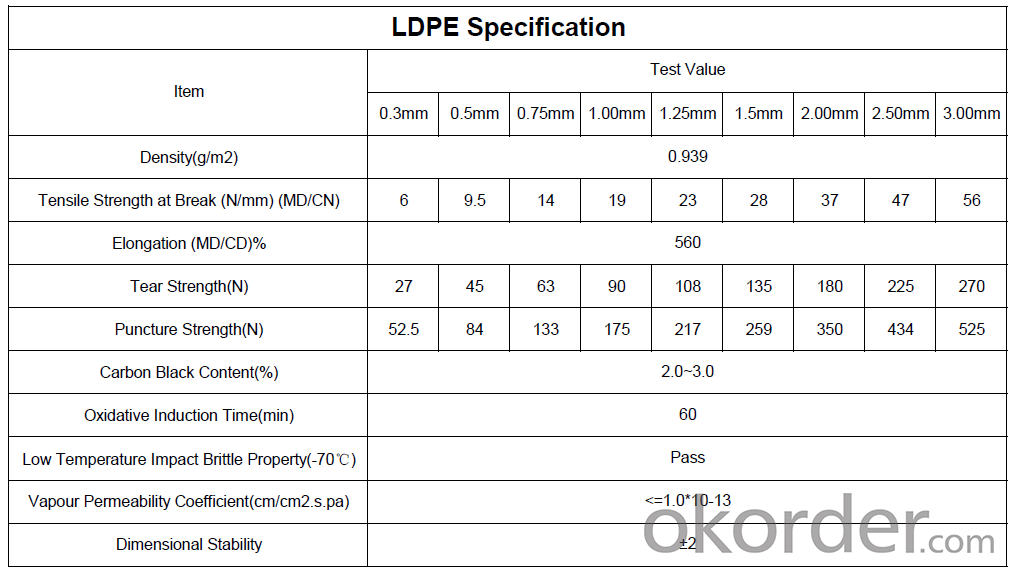

LDPE Geomembrane Specification

1)Material: LDPE

2)thickness:0.3mm~3.0mm

3)width:2m~7m

]] LDPE Geomembrane Package:

LDPE Geomembrane Package:

1. PE film inside, and Woven bag outside.

2. Packaged in container.

LDPE Geomembrane Application:

LDPE Geomembrane Application:

Landfill lining

Landfills capping

Water reservoirs

Pond-lining

Irrigation canals

Tunnels

Product Advantage

1.Some raw materials are produced by ourselves, or imported from overboard, so we could control the cost and quality to competitive in the market.

2. We have research team and laboratory, so we could research new products by ourselves and produce according client’s request.

3. There are more than fifty produce lines, so we could guarantee the delivery time.

4. We supply our products to many national projects in many countries, so our quality is stable and reliable.

5. If you have problem during your project when using our product, we could arrange our engineer to help.

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Can we get samples?

- A: Yes, we could arrange samples for free.

- Q:How to separate the non woven fabric from the waterproof board?

- Installation and construction of HDPE geomembrane shall be in accordance with the specific site condition and climatic conditions, properly pre-place 2%-5% extension volume; level surface mounting of base, remove the roots, stones and other sharp objects; trim round internal and external corners with its fillet radius equal to or more than 50cm; welding seam surface must be clean; welding seam should adopt displacement installation to avoid cross-wire welding, T-shape installation is available; using the side ditch anchoring landfill or bead seal installation; welding uses double track thermal melting, monorail hot melt, squeezing welding rod welding; seam take junction width is 10cm-15cm.

- Q:Can geomembranes be used in oil and gas storage applications?

- Yes, geomembranes can be used in oil and gas storage applications. Geomembranes are impermeable liners that are commonly used to contain and protect various types of liquids, including oil and gas. They are designed to provide a reliable barrier against leaks and contamination, making them suitable for storage tanks, secondary containment systems, and other oil and gas storage facilities.

- Q:What are the main functions of geomembranes?

- The main functions of geomembranes are to provide containment, separation, and protection. They are used to prevent the migration of fluids or gases, such as water or chemicals, in various applications such as landfill liners, pond liners, and mining operations. Geomembranes also act as a barrier to prevent the mixing of different materials, provide stability and reinforcement to soil, and protect against environmental degradation.

- Q:How do geomembranes contribute to the preservation of coastal ecosystems?

- Geomembranes contribute to the preservation of coastal ecosystems by providing a barrier that prevents the contamination of soil and water. They help control erosion, reduce the risk of pollution, and protect the natural habitats of coastal plants and animals. Additionally, geomembranes can be used for shoreline stabilization, preventing coastal erosion and preserving the integrity of the ecosystem.

- Q:How do geomembranes contribute to stormwater filtration?

- Geomembranes contribute to stormwater filtration by acting as a barrier that prevents contaminants and pollutants from infiltrating the soil or water bodies. They are designed to be impermeable, effectively containing and controlling stormwater runoff. This helps to reduce the risk of water pollution by preventing harmful substances, such as oil, chemicals, or sediment, from reaching natural water sources. Additionally, geomembranes can be combined with other filtration systems, like geotextiles or biofiltration cells, to further enhance the stormwater treatment process.

- Q:What is the difference between a smooth and textured geomembrane?

- The main difference between a smooth and textured geomembrane lies in their surface characteristics. A smooth geomembrane has a flat and even surface, while a textured geomembrane has a rougher texture with bumps or grooves. The choice between the two depends on the specific application and desired performance. Smooth geomembranes are typically used in situations where a high level of impermeability is required, such as in containment systems for hazardous waste or liquid storage. Textured geomembranes, on the other hand, are preferred in applications where enhanced friction or grip is needed, such as in landfill liners or slope stability projects. The texture helps to increase frictional resistance and improve stability.

- Q:The pool with geomembrane but not long enough for what glue pool

- Should be used in geotechnical membrane professional welding, not long enough to play a role in the prevention of leakage,

- Q:can RO membrane film be used to water purifier?

- Ro film isnot suitable for water purifier, mainly because it is soft water. Oh, it is not good to health.

- Q:What is the difference between cement pond lotus and geomembrane harvest?

- Now with a good quality of the new material film, seepage is not good, the general use of geotechnical membrane to do high cost of impermeable cement

- Q:Are geomembranes permeable to gases?

- No, geomembranes are generally not permeable to gases.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE Geomembrane Liner for Landfill lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords