ASTM HDPE Geomembrane for Aquiculture and Landfill Project Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geomembrane Detail Specifications:

Type: | Geomembranes | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | 0.1mm-4.0mm | Material: | EVA, HDPE, LDPE, LLDPE, PVC, HDPE | Thickness: | 0.1mm - 4.0mm |

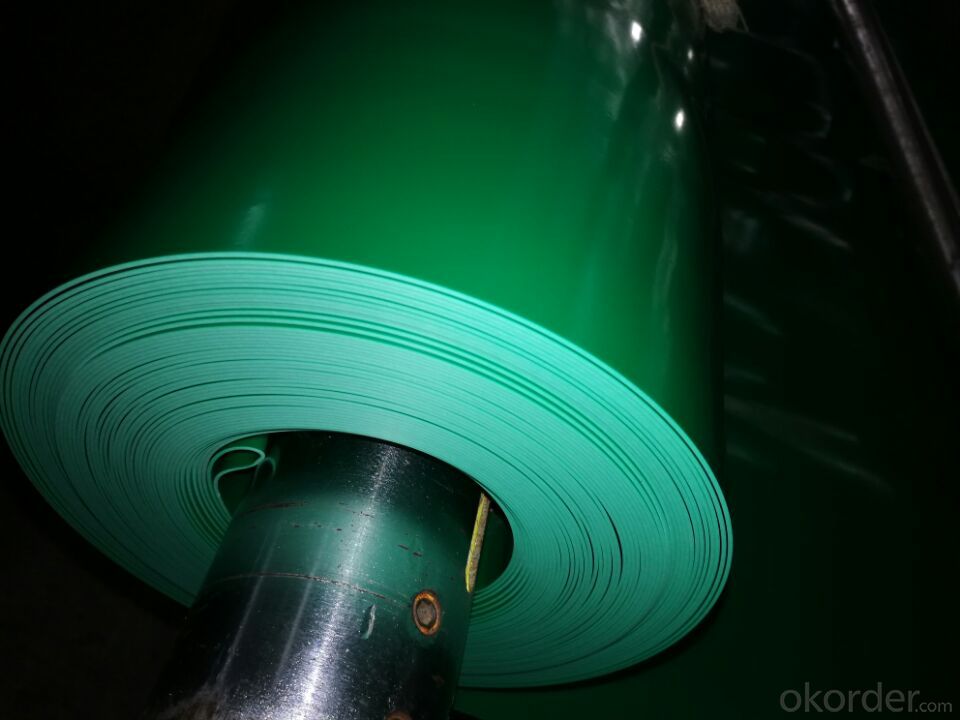

Color: | white, black, red ect. | Roll width: | 1m-8m | Roll length: | 50-100m |

MOQ: | 100 m2 | Certification: | CE/ISO9001/ ISO14001 | Sample: | available for free |

Package: | by PP woven bag | Payment: | by T/T |

HDPE Geomembrane Feature:

--Good mechanical properties

--High tear strength, deformation and adaptable, puncture resistance,

--Anti-aging, anti-ultraviolet-resistant,

--Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water,

--Drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications

and low cost, simple construction.

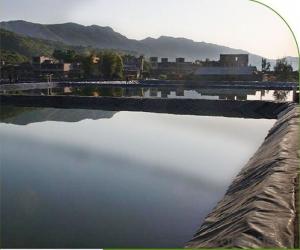

HDPE geomembrane Application:

1) Environmental protection sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE Geomembrane Packaging & Delivery:

Packaging Details: | HDPE geomembrane are packed into roll in PP woven geotextile or as client' s request |

Delivery Detail: | in 10 days after receive advance payment |

HDPE Geomembrane Photos:

- Q:What should be noticed when geomembrane is welding?

- The success of sewage treatment seepage control project depends on the quality of the geomembrane itself and the quality of its installation and construction.

- Q:Can geomembranes be used in floating covers for liquid storage?

- Yes, geomembranes can be used in floating covers for liquid storage. Geomembranes are impermeable membranes made of synthetic materials that can effectively contain and prevent the leakage of liquids. When used in floating covers, they can create a barrier between the liquid and the environment, effectively reducing evaporation and protecting the stored liquid from external contamination.

- Q:How are geomembranes tested for quality?

- Geomembranes are tested for quality through a series of rigorous tests and inspections. These tests usually include tests for physical properties like thickness, tensile strength, tear resistance, and puncture resistance. Additionally, they are subjected to chemical resistance tests to ensure their durability and resistance to various substances. Furthermore, geomembranes are examined for seam strength, weld integrity, and dimensional stability. These comprehensive quality tests help ensure that geomembranes meet the required standards and are fit for their intended applications.

- Q:Can geomembranes be installed on slopes?

- Yes, geomembranes can be installed on slopes. They are often used as a barrier or liner to prevent water seepage or soil erosion on slopes. The installation process may require additional measures to ensure proper anchoring and stability on the inclined surface.

- Q:what are the diamond film?

- Diamond film is glittering.

- Q:European electrothermal?film is good

- electrothermal?film is made of polyester film. When working with electrothermal?film as a heating element, the heat is sent into space in the form of radiation , the human body and the object first get warm, and the combined effect is better than traditional convection heating. low temperature radiation electrothermal film system consists of power?supply, temperature?controller, adapting piece, insulating layer, electrothermal?film and finish?coat layer. Power supply via wires connecting the electric film, turning the electric energy into heat energy. Since the electrothermal?film is purely resistance circuit, so the high conversion is efficient, in addition to the loss of a small portion (2%), the majority (98%) is converted into heat energy. Electric film can not be directly used for radiant floor heating, it needs to add additional patent PVC vacuum envelope, thus it can be used for floor heating, and ensure the use effects and life.

- Q:Polyethylene geomembrane perennial soaked in water will not release harmful gases

- soil cylinder and hydraulic oil. when operational pressure reaches dozens of MPa, hydraulic oil will be soaked in water. Since the water density is smaller than that of oil, so it is easy to mix them.

- Q:The welding temperature of 1.5mm thick geomembrane.

- 1. The welding temperature of 1.5mm thick geomembrane is 200-350℃. 2. The welding temperature of geomembrane is influenced by thickness and external climate. 3. The welding temperature of geomembrane during summer construction is low, while the welding temperature of geomembrane during autumn and winter construction is high. 4. The running speed of geomembrane welder needs to be adjusted except that the temperature of geomembrane welder needs to be adjusted during the welding of geomembrane. Reasonable welding temperature of geomembrane and reasonable running speed of geomembrane welder can make the welding reach standards.

- Q:How to stick the film on the bathroom window?

- You can spray water on the glass. It doesn't matter if water flows down. After the film is stuck, bubbles at the bottom is easy to be scrape out with a scraper and it will dry over a period of time. It will be stuck firmly and flat. If there are still bubbles, you can prick it with a needle to release the air.

- Q:What is the mechanism of vacuum tube coating?

- The mechanism vacuum coating is that the membrane body is evaporated to the surface of the workpiece at a high temperature and crystallizes. Since the air will obstruct the evaporated membrane molecules, making the crystalline rough and dim, crystalline can only be exquisite and glossy under the environment of high vacuum. If the vacuum degree is not high, the crystalline will lose its luster and the adhesion is also very poor. Early vacuum coating which relied on the evaporated items to scatter naturally is of poor adhesion, low efficiency, and poor glossiness. Now intermediate frequency magnetron sputtering target is used. the evaporated molecules of the membrane bombard the target under the effect of an electric field at faster speed and sputter a large number of target atoms. Neutral target atoms (or molecules) is deposited on a substrate and become the film, which solves the problem that some films can not be processed through natural evaporation formation, such as titanize and plate zirconium. Currently aluminum nitrogen complex films are widely used in vacuum tubes. The film layer can be divided to the interior, middle and exterior layer and all have their own function. As a reflective layer, the inner layer is mainly used to prevent the heat of the hot water in the pipe from radiating outward; the middle layer is an absorbing layer and the main function of it is to absorb energy and transform the energy into heat; the exterior layer is an anti-reflection layer, which is mainly used to reduce the sun reflection and increase the absorption rate of sunlight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM HDPE Geomembrane for Aquiculture and Landfill Project Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords