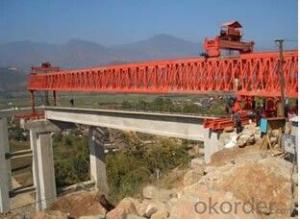

Launching gantry in span by span

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tyre trolley transfers the concrete segment to the rear of the launching gantry. The lifting trolley of the gantry lifts the concrete segment to the assembly position and the steeve hangs up the segment. After assembly, these segments tighten together with stressing wires, and the gantry put the beam on the pier and fulfill the construction of bridge segment. Based on the requirement of our client and the bridge conditions, the erection span and lifting capacity could be modified and customied for each machine.

530 ton Launching Gantry in span by span 100 ton Launching Gantry in span by span

General design data:

·Max span : 35m

·Max weight of each segment : 45ton (60ton)

·Max weight of span : 460ton(530ton)

·max longitudinal slope of bridge :±3%

·max transversal slope of bridge :±2%

·min horizontal radium : 600m(400m)

·Max wind speed on working condition : 22m/s

·Max win speed on static condition :35m/s

·Safety coefficient :≥2.5

·Stability factor of launching gantry :1.3

·Launching gantry’s fixing connection can be resistant emergencyconditions such as strong wind and typhoon.

·Temperature :from -10℃ to +40℃

·Relative humidity :90%

·The whole machine can move backward and forward for bridge erection.

- Q:How many special operators do you need to build a bridge machine? What kind of special operations personnel should be held?

- Special personnel operating permit, is generally the operator, the equipment supplier training is generally issued training certificate. Can operate

- Q:Our original home is the height of the beam is now 3m to 2.6 of the beam is not to the bridge before the support leg height

- Bridging machine if you need to transform the manufacturers must contact. The influence of the height of the beam on the condition of the bridge girder erection machine may need to be studied by experts.

- Q:Bridging machine construction method? Common types of bridge machine

- But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q:2700t bridging machine assembly summary how to write

- Emphasizing the importance of safety and management.No model.The following for reference,

- Q:DJ180 bridge machine how to run?

- Four. When the bridge crane carries the concrete beam, the front leg part of the bridge crane is required to be fixed by the hand pulling block (5T).Five, when installing the bridge with the upper and lower longitudinal slope, the longitudinal displacement of the bridge erecting machine should be prevented from sliding. For example: the triangle iron for protection on wheels before and after, especially in the leg from the beam end is near, shift to the attention of control.Six, after the erection of the bridge crane must be suspended hanging crane operation, but also can be used to test the concrete beam, bridge erection machine running in place to start the installation work.

- Q:Now the high-speed rail bridge frame span of the beam

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier

- Q:Bridging machine belongs to special equipment

- Pressure vessels (including gas cylinders, the same below), pressure pipes, elevators, lifting machinery, passenger ropeway, large recreational facilities and field (plant) special motor vehicles.

- Q:What is bridging agent? What is the main purpose?

- Bridging agent formula: [C6H5C (CH3) 2O]2 molecular weight

- Q:I would like to ask what types of bridge machine

- Bridge machine from the use of points, can be divided into highway bridge, railway bridge machine. Can also be divided according to the different structure, the name is more, for example, the auxiliary beam type, the whole frame, tunnel, etc.. Can also be based on the way to set the sub section of the assembly type, the whole hole, etc.

- Q:Summary of bridge crane driver

- Write the main content of the work, how to work hard, the results achieved, and finally put forward some reasonable proposals or new efforts.......

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Launching gantry in span by span

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords