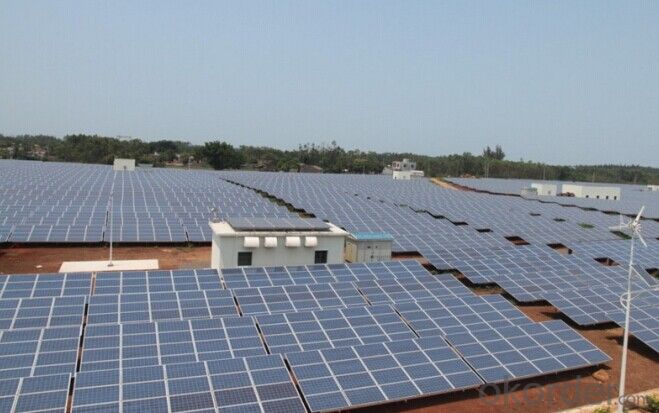

Large Scale Ground Joint Horizontal Axis Tracking System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Large scale ground joint horizontal axis tracking system

Tracking system used in solar plant

Performance Feature:

single set horizontal axis tracking system is that:

1. the advantage conpared with the fixed mounting system.cover the same area as the fixed mounting system.

2. power generating can be increased by 10-30%.the foundation scale is the same as the fixed mounting system.

3. the comprehensive costs are much lower than the fixed mounting system.

4. suitable fooe the min-low latitude areas and comples terrain.

5. the large gronud area ,color steel tile roof and etc.

6. thefirst input only need 2 years to recover costs,and the investors will receive10-30% annual generating incomes more than 20 years.

•installed capacity | • 1KW—10KW |

•control method | •Light control •time control •light/time control |

•tracking accurancy | • ≤1° |

•Azimuth angle | • ±45° |

•Working wind | • 50—70km/h |

•Max wind resistance | • 125—200km/h |

•Driven power | • DC24V/≤30W |

•Structural material | • Q 2 3 5 •hot-dip galvanized steel |

•level of protection | • IP65 |

•Quality guarantee | • 25Y/2Y |

•Operating ambient temperature | • -35℃—65℃ |

•Area of net rack | • 10㎡—80㎡ |

•Unit weight | • 200kg——2000kg |

- Q:What is the difference between a roof-mounted and ground-mounted solar system?

- A roof-mounted solar system refers to solar panels that are installed on the roof of a building, while a ground-mounted solar system refers to panels that are installed on the ground. The main difference lies in the placement and orientation of the panels. Roof-mounted systems are commonly used when space is limited or to utilize the available roof area for solar energy production. On the other hand, ground-mounted systems are installed on the ground and can be placed at an optimal angle and direction to maximize sunlight exposure, making them more flexible in terms of positioning and potential energy output.

- Q:Are there any specific requirements for tracking system compatibility when using a solar mounting system?

- Yes, there are specific requirements for tracking system compatibility when using a solar mounting system. The tracking system should be able to integrate with the mounting system and provide the necessary support and functionality for the solar panels. It is important to ensure that the mounting system and tracking system are designed to work together to maximize the efficiency and performance of the solar installation.

- Q:Are there any specific requirements for pergola or shade structure design when using a solar mounting system?

- Yes, there are specific requirements for pergola or shade structure design when using a solar mounting system. These requirements primarily include ensuring structural integrity and stability to support the weight of the solar panels. Additionally, the design should allow for proper airflow around the panels to prevent overheating. It is also important to consider the orientation and tilt angle of the panels for optimal solar energy production.

- Q:Can a solar mounting system be used with solar-powered camping equipment?

- Yes, a solar mounting system can be used with solar-powered camping equipment. The mounting system allows for easy installation and positioning of solar panels, which can then be used to power various camping equipment such as lights, chargers, and portable fans. This setup provides a sustainable and convenient solution for accessing renewable energy while camping.

- Q:Can solar mounting systems be used for both residential and commercial installations?

- Yes, solar mounting systems can be used for both residential and commercial installations. These systems are versatile and adjustable to accommodate various roof types and sizes, making them suitable for both residential homes and commercial buildings. Additionally, they can be customized to meet the specific energy needs of each installation, whether it's for a small residential property or a large commercial facility.

- Q:Are there any specific requirements for facade or cladding design when using a solar mounting system?

- Yes, there are specific requirements for facade or cladding design when using a solar mounting system. The design must consider factors such as the weight and structural load of the solar panels, as well as the integration and compatibility with the cladding materials. Additionally, the design should account for proper ventilation and water drainage to ensure the longevity and performance of the solar system.

- Q:Can a solar mounting system be used with solar curtain walls?

- Yes, a solar mounting system can be used with solar curtain walls. The mounting system provides the necessary support and stability for the solar panels installed on the curtain wall. This combination allows for efficient utilization of building surfaces and enhances the overall energy production of the solar system.

- Q:What is a high-profile template system?

- Large template support system refers to the construction of the construction site concrete component template support height of more than 8m, or erection span of more than 18m, or the total load of more than 15kN / ㎡, or concentrated line load greater than 20kN / m template support system.

- Q:Can a solar mounting system be used in areas with limited access to electric vehicle charging infrastructure?

- Yes, a solar mounting system can be used in areas with limited access to electric vehicle charging infrastructure. Solar mounting systems harness solar energy to generate electricity, which can be used to charge electric vehicles. This provides an alternative charging solution for areas without traditional charging infrastructure, utilizing renewable energy sources and promoting sustainable transportation.

- Q:How do solar mounting systems interact with electrical wiring and inverters?

- Solar mounting systems interact with electrical wiring and inverters by connecting the photovoltaic (PV) panels to the inverter and the electrical grid. The mounting system securely holds the PV panels in place, and the electrical wiring connects the panels to the inverter, which converts the DC power generated by the panels into AC power suitable for use in homes or businesses. The inverters are typically installed near the electrical panel, where the AC power is then fed into the building's electrical system or back into the grid. Overall, the solar mounting systems play a crucial role in ensuring proper installation and electrical connectivity for efficient and safe solar power generation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Large Scale Ground Joint Horizontal Axis Tracking System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords