Large diameter longitudinal submerged arc welded pipe API

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification of large diameter longitudinal submerged arc welded pipe:

1)Application: It is widely applied to line pipe in oil and sewage transportation , and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

2)Grade:API 5L GR.B, X40, X42, X52, X56, X60, X65, X70.ST37/37-2,ST33,ST35.8,ST35.4.GB 9711.1/SY5037/GB3092

3)Standard:ASTM A53,ASTM A671 ,ASTM A672 .ASTM A252 API 5L (PSL-1,PSL-2) ,API 5L 2B ,2H,2W.DIN1626,DIN17175,DIN1629.JISG 3452,JISG3457/3456,JISG3461.GB 9711.1/SY5037/GB3092

2.Size of large diameter longitudinal submerged arc welded pipe:

OD: 406.4MM-1422MM (16”-56”)

Thickness: 8MM-50.8MM depends on OD

3.Data Sheet for large diameter longitudinal submerged arc welded pipe:

Standard: APISPEC 5L

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

| Min | Max | Min | Max | |

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 | 517 | 758 | |

×65 | 448 | 600 | 531 | 758 | |

×70 | 483 | 621 | 565 | 758 | |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S | CEV |

Max | Max | Max | Max | Max | ||

PSL1 |

- | |||||

B | 0.26 | 1.2 | 0.030 | 0.030 | ||

×42 | 0.26 | 1.3 | 0.030 | 0.030 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | ||

PSL2 |

0.43 | |||||

B | 0.22 | 1.20 | 0.025 | 0.015 | ||

×42 | 0.22 | 1.30 | 0.025 | 0.015 | ||

×46,×52,×56, X60 | 0.22 | 1.40 | 0.025 | 0.015 | ||

X65 | 0.22 | 1.45 | 0.025 | 0.015 | ||

X70 | 0.22 | 1.65 | 0.025 | 0.015 | ||

4. Packing & Delivery

Packing Detail: bundles with anti-rust painting and with plastic caps

Delivery Term: 30 days after receving payment or L/C

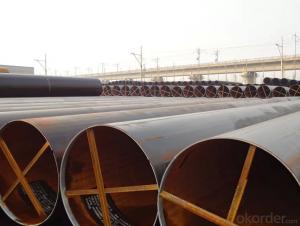

5. Products picture for large diameter longitudinal submerged arc welded pipe:

6. FAQ of large diameter longitudinal submerged arc welded pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

- Q:Are steel pipes suitable for underground installations?

- Indeed, steel pipes prove to be a fitting option for underground installations. Their durability, strength, and resistance to corrosion have made them a widely utilized choice for such applications. Able to endure high pressure and extreme temperature fluctuations, steel pipes are well-suited for transporting a variety of substances underground, including water, gas, and oil. Moreover, their exceptional resistance to environmental elements such as moisture and chemicals, commonly encountered in underground environments, further enhances their suitability. By implementing appropriate coatings and cathodic protection systems, steel pipes can enjoy an extended lifespan and retain their integrity even under harsh underground conditions. Consequently, steel pipes emerge as a dependable and fitting selection for underground installations.

- Q:What are the different types of steel pipe reducers?

- There are several different types of steel pipe reducers that are commonly used in various industrial applications. These reducers are designed to connect pipes of different sizes, allowing for a smooth transition in the flow of fluids or gases. Here are some of the most common types: 1. Concentric Reducers: These reducers have a symmetrical design with a centerline that aligns with the centerline of both the larger and smaller pipes. They provide a gradual reduction in pipe size, ensuring a smooth flow of material. 2. Eccentric Reducers: Unlike concentric reducers, eccentric reducers have an offset centerline. This design is useful when there is a need to prevent the accumulation of air or gases in the piping system. The eccentric reducer helps to direct any gas or air towards a vent or drain point. 3. Welded Reducers: These reducers are made by welding two pipes of different sizes together. They are commonly used in situations where a permanent connection is required. 4. Seamless Reducers: Seamless reducers are manufactured without any welded joints. They are made from a single piece of steel, which enhances their strength and durability. Seamless reducers are often preferred in applications where leak-proof connections are critical, such as in high-pressure or high-temperature environments. 5. Threaded Reducers: These reducers have male and female threads on either end, allowing for easy installation and removal. They are commonly used in low-pressure applications and are an economical choice for systems that require frequent disassembly. 6. Flanged Reducers: Flanged reducers have flanges on both ends, which are bolted together to create a tight seal. They are often used in piping systems that require easy access for maintenance or inspection. Each type of steel pipe reducer has its own advantages and is selected based on the specific requirements of the application. It is important to consider factors such as the type of fluid or gas being transported, pressure and temperature conditions, and the need for easy installation or maintenance when choosing the appropriate reducer for a particular system.

- Q:How are steel pipes used in the construction of industrial facilities?

- Steel pipes are commonly used in the construction of industrial facilities for various purposes such as transporting fluids, gases, and steam, as well as providing structural support and carrying electrical wiring. They are durable, resistant to corrosion, and can withstand high pressure and temperature, making them ideal for industrial settings.

- Q:What are the factors to consider when selecting a steel pipe for a specific application?

- When selecting a steel pipe for a specific application, there are several key factors to consider. These include the desired strength and hardness of the pipe, its corrosion resistance, its ability to withstand high temperatures or extreme conditions, its compatibility with the intended fluid or gas, the required dimensions and specifications, as well as the cost and availability of the pipe. It is also important to assess the specific requirements and demands of the application to ensure the selected steel pipe will meet the desired performance and longevity.

- Q:Can steel pipes be used for underground fuel storage systems?

- Steel pipes are an excellent choice for underground fuel storage systems. Due to their strength, durability, and resistance to corrosion, they are widely used in this application. By opting for steel pipes, one can rely on a secure and long-lasting solution for underground fuel storage. These pipes are capable of withstanding the pressure and weight of the fuel, making them suitable for this purpose. Moreover, their easy weldability and interconnectivity provide flexibility in designing and constructing such systems. However, it is crucial to ensure that the steel pipes used in underground fuel storage systems are properly coated or lined to prevent corrosion and protect the fuel from contamination. Regular inspections and maintenance play a vital role in identifying and addressing any potential issues that may arise.

- Q:What are the environmental impacts of steel pipe manufacturing?

- The environmental impacts of steel pipe manufacturing include the extraction and mining of raw materials, such as iron ore and coal, which can lead to habitat destruction and pollution. The steel production process consumes significant amounts of energy and releases greenhouse gases, contributing to climate change. Additionally, the production of steel pipes involves the use of chemicals and toxic substances, which can contaminate water sources and harm ecosystems. Proper waste management and the adoption of sustainable practices can help mitigate these impacts.

- Q:How are steel pipes used in irrigation systems?

- Steel pipes are commonly used in irrigation systems to transport water from a water source, such as a well or reservoir, to the fields or crops that need to be irrigated. These pipes are durable, strong, and resistant to weathering and corrosion, making them ideal for outdoor use. They can be laid underground or above ground, and their flexibility allows for easy installation and maintenance. Steel pipes in irrigation systems ensure a reliable and efficient water supply to promote healthy plant growth and maximize crop yields.

- Q:What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on the specific needs and requirements of a project. However, steel pipes are commonly available in diameters ranging from 1/8 inch to 72 inches or even larger.

- Q:What is hot rolled steel pipe? What is a cold drawn steel tube?

- Seamless steel pipe, hot-rolled and cold-rolled (DIAL) seamless steel pipe two categories.Hot rolled steel tubes are divided into ordinary steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy steel pipes, stainless steel pipes, oil cracking pipes, geological steel pipes and other steel pipes, etc..Cold rolled seamless steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube and other steel tube, including carbon thin-walled steel, alloy thin-walled steel, stainless steel, thin steel tube. The outer diameter of hot-rolled seamless tube is generally greater than 32mm, the wall thickness is 2.5-75mm. The outer diameter of cold-rolled seamless steel tube can reach 6mm, the wall thickness can be up to 0.25mm, the outer diameter of thin-wall pipe can be 5mm, the wall thickness is less than 0.25mm, and cold rolling has higher precision than hot rolling dimension.

- Q:What does seamless steel tube mean? What are the main uses? What are the classifications?

- The production process of seamless steel tube in general can be divided into two kinds of hot rolling and cold drawing, cold-rolled seamless steel pipe production process than hot-rolled billet to complex, first to three roller rolling and extrusion to sizing test, if the tube through the cutting machine cutting surface without crack growth response after cutting blank about one meter. Then enter the annealing process, annealing and pickling to use acid pickling liquid, should pay attention to the surface if there are a lot of bubbling, if there are a large number of bubbling pipe shows that the quality is not up to the standard. The appearance of cold rolling seamless steel tube shorter than hot-rolled seamless steel pipe, cold rolled seamless steel pipe wall thickness is generally higher than hot-rolled seamless steel pipe to be small, but the surface looks better than thick wall seamless steel pipe is more bright, rough surface is not too much, not too much burr diameter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Large diameter longitudinal submerged arc welded pipe API

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords