Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing:

Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing are processing with imported materials ,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing mainly used in the manufacture of thin films, containers, pipes, wire, wire and cable, and other daily necessities, and can be used as high frequency television, radar and other insulating material. the best choice for all kinds of products ‘packaging.

2. Main Features of Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing:

Bottom Sealed Flat PE Unprinted Bags is Polyethylene odorless, non-toxic, feels like wax, has excellent resistance to low temperature performance (minimum temperature is -70 ~ -100 °C), good chemical stability, erosion resistant to most acids (not resistant to oxidizing acid), at room temperature not soluble in common solvents, water absorption, excellent electrical insulation properties.

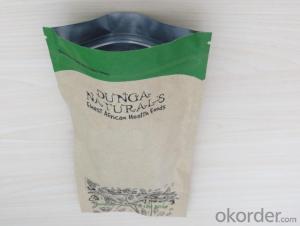

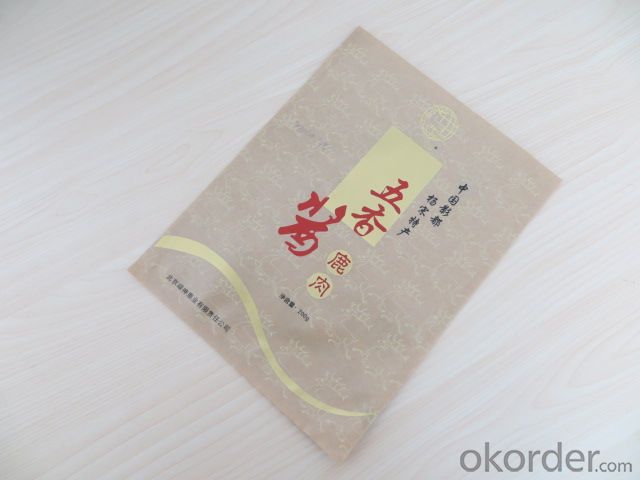

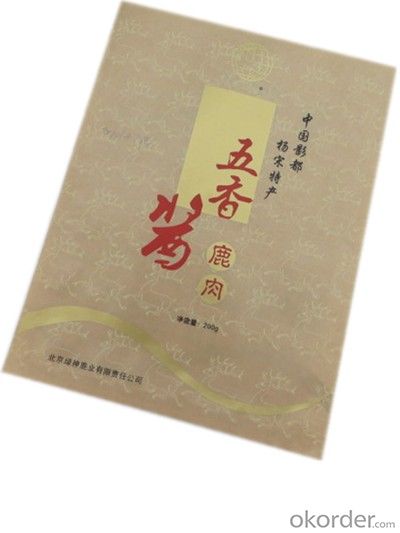

3. Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing Images:

4. Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:0.03mm-0.15mm

4.Form:top open bag,ziplock bag, or Unprinted bag

5.FAQ of Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What's the size of the 5 kg vacuum bag, please?

- According to the facts, tailored products! The sizes of various products are different!

- Q:What ink is the food packing bag printed on?

- At present, in the food plastic packaging and printing, the most widely used is the benzene soluble chlorinated polypropylene ink series. This series of ink production and application technology have been very mature, is mainly used for the gravure printing in BOPP (BOPP) on printing and printing adaptability is very excellent, good processing performance, faster drying. However, there are still many deficiencies in this method of printing.

- Q:Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- PET thin film / foil / nylon //PE thin film, it is best for the duck packaging, the longest period of hedging. Of course, there are some other place form, slightly reduce some costs, such as the PET// //PE aluminum foil film, but the effect was not as good as the former good bag, a bag to reduce the cost of not much, but the effect is significantly reduced, so it is recommended to use the former.

- Q:What is the difference between LDPE and PE-LD in a package?

- LDPE is low density polyethylene, and PE-LD should be low density polyethylene. Because according to the PE classification, LDPE (low density polyethylene), MDPE (medium density polyethylene), HDPE (high density polyethylene), VLDPE (low density polyethylene), LLDPE (linear low density polyethylene (mPE), metallocene PE). See, "LD" means "low density".

- Q:What are the requirements of the mark on the cement packing bag?

- Label on cement packing bagCommon C25, C30, C35, C40 label is the cement packaging machine packaging cement mark, specific what label, drawings will generally indicate, general use C25 on the line, the greater the strength higher.

- Q:What are the requirements of the gas in the package?

- Some of the most common baked foods, moon cakes, fried foods, potato chips, which are filled with nitrogen, are required to be food grade, high purity, minimum requirement is no harmful gas impurities!

- Q:What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

- Q:How big is the vacuum pack 28*40cm?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q:What are the soft and hard sides of plastic bags? Material or process technology?

- In general, the soft, and toughness and strength are greater, the quality is the best, most durable. Of course, the price should be higher.As for you, which kind of good, depends on your use, cheap, and can meet the use of, that is good, not necessarily have to buy many high priced! The one that suits you is the best!

- Q:Express carton packaging, plastic packaging should be how to deal with?

- For those cartons, environmentalists have their own ways of using them. "The Jingdong loves to use plastic bags, and Amazon and its customers prefer cartons."." Some of the more orderly carton, you can keep as a storage box. You can use the marker pen to write the contents on the carton, then stack it on the bottom of the cupboard to improve the space utilization. For some cartons that cannot be used for the time being, use the tape on the carton to flatten the cartons.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords