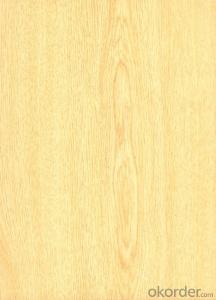

Laminate Flooring 8mm Export to Europe with 2mm EVA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Laminate flooring is a multi-layer synthetic flooring product, fused together with a laminationprocess. Laminate flooring ismost often four layers of materials,From topto bottom is Durable Overlay, Decorative Paper, HDF board, Balance Paper.

Durable Overlay is made by applying an AL2O3 solution over transparent paper, AL2O3 is very fineand thus it does not hide the color and design of the decorative paper.

Decorative Paperis a computer made paper which imitates natural wood, stone etc, by applying AL2O3to decorative paper, the latter becomes protected from the environment.

HDF board are made of wood fiber compressed into a high density panel (≥880kgs/m3).

Balance Paper is the thick and strong paper treated with AL2O3 on the back of laminate flooring,it gives stability to the laminate flooring boards and provide a measure ofisolation from under-floor humidity.

Wear Rating:

Durable Overlay Thickness | Applying Place | Euro Grade | EN438 | EN13329 | China National Stand |

22g/m2 | 21 Family Low Grade | AC1 | 2000 | ≥600 | 1500 |

33g/m2 | 22 Family Medium Grade | AC2 | 4000 | ≥900 | 2500 |

39g/m2 | 23 Family High Grade | AC3 | 6000 | ≥1800 | 4000 |

45g/m2 | 31 Commercial Low Grade | AC3 | 9000 | ≥2500 | 6000 |

62g/m2 | 32 Commercial Medium Grade | AC4 | 12000 | ≥4000 | 9000 |

76g/m2 | 33 Commercial High Grade | AC5 | 15000 | ≥6500 | 12000 |

Formaldehyde Emission:E1

Moisture Content:≤12%

Surface: Mirror, Middle Emboss, Fine Emboss, Crystal, Hand Scraped

Specification:

Thickness: 7.3mm,8.3mm, 12.3mm, 15.3mm

Based on order, other specification are alsoavailable.

Packing: 8-10 pieces per carton, 35-60 cartons perpallet, about 20 pallets per container.

- Q:Living room is floor tiles, bedroom to shop composite floor how to leveling?

- 1: the use of cement and sand can be leveling, this way the floor dry slow, if the time is not urgent, then you can use the cost of about 25 yuan per square meter or so, and so will be able to shop floor floor 2: mats, popular That is thicker than the bubble, but his density is thick, from 1cm to 5cm thickness has, the price from 10 to 20 or so, but this method, the floor is better than the flat 3 wooden keel leveling, if Your floor is 1.2 thick keel density in the distance of about 20cm, if the thickness of the distance of 30cm can be 30cm spacing, such as the law for the use of hard to wear a quig if the sickle is 0.9 or so will be in the top layer of a layer of nine , So the cost will be higher, to forty per square meter, if the light keel leveling, about 35 or so, materials and labor are included.

- Q:Home shop is a composite floor, five years, the recent total in the door seams found similar nibble sweater insects, dark red, big head small tail, the tail there are long hair, some hard, but also molting, a centimeter long, Ask the experts to answer what's going on? Began to think that the wool is born, and later found not, because the total appearance, clean up a seam, stop two or three days to see there, so I suspect the floor insects, and how to do? Why the composite floor will be raw insects? Home decoration is the ground Qinghu raft Hong Kong fan drum song attack card sweep is very clean, under the floor is the bubble and plastic, according to reason not raw ah, please professional answer! Other answers I have seen not suitable for me, do not paste it! The The More

- Insects need to have a certain degree of humidity and temperature, so if the floor of the insects, the vast majority of the reasons for the dampness of the disaster, so the key is pest control moisture. Experts, many users are paying attention to the surface of the decoration problems, and some hidden works are often overlooked, especially for the straight shop of wood flooring, the ground leveling is very important, the general hair is best to use dry powder to light , Because the hair of the exposed sand, but the temporary absorption of water, meet the appropriate environment will be the tiger raft Hong Kong drums wind attack card water release again. The dry powder can not only absorb the excess water can also play a protective film to lock the role of moisture, to prevent back tide, but also conducive to effectively measure the ground flatness. Some people think that the wooden floor pavement before the ground sprinkle a layer of charcoal, charcoal or pepper and other things can effectively prevent the insects, experts believe that this approach is not desirable. Charcoal, charcoal, although in the short term can absorb moisture, but does not digest the moisture, often again released, the same can not reach the purpose of moisture. And the practice of pepper is not desirable, usually dry pepper can be insect repellent, but many examples show that pepper is often caused by wet insects and then caused the floor insects. So, the best way is to do a layer of moisture to the ground to deal with, or more brush a layer of moisture-proof paint.

- Q:Composite floor was blisters, how to do?

- Composite floor was blisters, how to do?

- Q:After the wooden floor is installed, it is much higher than the original floor, and I know that the tiles are at least 5 centimeters higher than the original ground. More

- Wood floors are generally 12 cm 15 cm, but 12 cm is still the majority! So the thickness of the wood floor is higher than the part!

- Q:Thinking of replacing 12X12 vinyl kitchen covering.Plz. give highlites of the install and if you liked the results.Thnx.

- Beautiful stuff once it's all laid out but it's a very hard wood to work. The material itself is quite dense so you will need a carbide blade for sure to cut it and metal-cutting on a saber-saw. Even nailing it down was a bit of an ordeal, the stuff is so hard that it would bend about every third nail out of the floor-nailer. My client bought a mixed lot of light to dark woods and I found the lighter ones to be a bit softer thus easier to cut/nail. Like I said it was beautiful once I got it down but ..........

- Q:How to identify the quality of composite flooring?

- First, the color of paper, look at the surface of the color is naturally not really second, wear-resistant layer, to see the surface of the wear resistance, the state to achieve more than 4500 turn can be used in the family, the general manufacturers have reached more than 6000 rpm Third, the environmental protection level traces of Cao Ke 丨 long check Hsue magic, is the release of formaldehyde

- Q:Only a lot of white color on the surface, it seems white, especially uncomfortable, but not all are white, and with the time of the time, There are more and more places to go and fall. Will it be the same as the original color? Sincerely ask which teacher to help solve more

- The floor is divided into 4 layers 1, wear-resistant paper 2, decorative paper 3, substrate 4, balance paper you should be the surface of the surface problems 1, the number of wear-resistant paper low wear resistance is not up to standard 6000 or more do not know when you buy the floor when asked no 2, the decorative paper worn off this will be set off Ji hair irrigation He Guai Gu Gui pharynx out of the substrate out of your problem is the quality of the floor is not the cause of repair Repaired to buy only half a year I guess when you buy the price is not too high 60 below it

- Q:How is the use of solid wood flooring? How long is life?

- It is good to use, but it must be good

- Q:dont know which method to install engineered floor on concrete i live in upland ca . float on cork or redux underlayment.or glued downadhessive 3 in 1 best overall methods

- Which type of flooring (of the engineered) do you have? They come both ways and can be installed in the way they come. The flooring ( click and lock system) must be installed that way. Any other type, if they don t specify it, must be glued od stapled. And since you said over slab, it must be glued down. Each way works well, Just find the method you like since gluing can be messy and costly( for the glue) but easier for some people to install. And the floating system is a bit harder to do if your not handy. But is cheaper w/o glue. Any questions you can e mail me through my avatar. I ve attended several installation seminars as well as installed a few 100,000 s/f.. GL

- Q:The use of composite flooring for a long time, a little dirty, dark, in the supermarket in the sea over the fall of the name of the law, but the feeling of no effect, there is no other better way to clean the complex cleaning floor. The composite floor color itself is a little light, so a dirty, to see the special clear. Thank you heroes Weapon. More

- Buy the perfect product cleaning detergent easy to clean.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Laminate Flooring 8mm Export to Europe with 2mm EVA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords