Ladle Shroud long nozzle Chinese steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Steelmaking long nozzle /refractory materials/refractory nozzles

steelmaking zircon nozzle Zr content 94-95% , and nozzle with metal shell ,

can protect nozzle burst.the casting temperature normally at 1520-1580 ℃.

our zirconia cores temperature resistance up to 2000℃, density is 4.2g/cm3 .

Steelmaking tundish nozzle zircon core contact face made a little big than other,effectively protect the nozzle using life.

tundish zirconia nozzles materials is alumina-zirconia-carbon .composed by Alumina-Carbon Shell, and zirconia core.

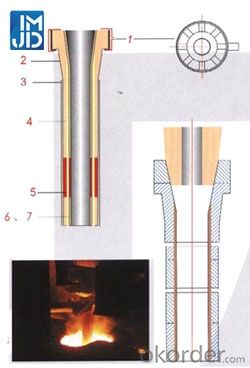

Graphic illustration:

1.Argon injection structure depending on customer specifications.

2.Ceramic glaze layer to prevent the material oxidation effectively.

3.Ceramic fiber blanket to prevent heat lost during casting.

4.High quality Al-C materials having high corrosion and thermal shock resistance.

5.High quality Zr-based composite to provide high corrosion resistance at the slag line.

6.Non-graphite based mased materials to meet the requirements of producing low carbon steel,silicon steel and high purity steel.

Manufacturing and QC

1.Raw materials blending

Independent raw materials blending center to assurestrict control of materials quality.

2.Shaping

Isostatic pressing technoloty,with as 1000 tons of pressure to assure the homogenous bulk density of each product.

3.Machining

To assure the uniform shape,dimension and dimension tolerance of each product.

4.X-ray defect inspection

To assure all products supplied to our customers without any defect and to prevent the un-countable feconomic loss for our customers.

5.Physical and chemistry analysis

To assure all products meet the physical and chemistry characteristics.

6.Packaging

The world-class for packaging to assure the safety transportation.

- Q:How do monolithic refractories protect the lining of ladles and tundishes?

- Monolithic refractories protect the lining of ladles and tundishes by forming a strong and durable barrier against high temperatures, chemical reactions, and mechanical stresses. These refractories are designed to be resistant to thermal shock and erosion, ensuring that the lining remains intact and unaffected by the molten metal or slag. They also provide insulation, minimizing heat loss and reducing energy consumption. Overall, monolithic refractories act as a reliable shield, extending the lifespan of the ladles and tundishes and preventing any detrimental effects on the lining.

- Q:How do monolithic refractories resist chemical attacks from molten metals and slag?

- Monolithic refractories are engineered to withstand chemical attacks caused by molten metals and slag. They possess various essential qualities that enable them to endure such harsh conditions. To begin with, monolithic refractories comprise top-notch materials with exceptional chemical resistance. These materials, including alumina, magnesia, and chrome, have a high melting point and remain stable even when exposed to extreme temperatures and corrosive substances. This chemical stability ensures that the refractory maintains its integrity and structural strength when in contact with molten metals and slag. Moreover, monolithic refractories have a compact and dense structure. This microstructure serves as a barrier, preventing molten metals and slag from penetrating the refractory material. By limiting the contact between the corrosive substances and the refractory, the dense structure reduces the likelihood of chemical reactions and erosion, thereby enhancing the refractory's resistance to chemical attacks. Additionally, monolithic refractories often contain additives and binders that enhance their chemical resistance. These additives form a protective layer on the refractory surface, acting as a shield against chemical attacks. They can also react with certain corrosive substances, forming stable compounds that further inhibit the penetration and corrosion of the refractory material. Furthermore, monolithic refractories are designed to have minimal porosity. This low porosity minimizes the absorption of molten metals and slag, preventing them from infiltrating the refractory and causing damage. By reducing the permeability of the material, the refractory can maintain its structural integrity and resist chemical attacks for extended periods. In conclusion, monolithic refractories withstand chemical attacks from molten metals and slag due to their high-quality materials, dense structure, additives, and low porosity. These combined properties enable the refractories to endure aggressive environments and maintain their performance and longevity in industrial applications.

- Q:What are the key properties of ramming mixes used for monolithic refractory installations?

- Ramming mixes for monolithic refractory installations must possess several key properties. Firstly, they need to have high thermal stability to withstand extreme temperatures and thermal cycling. This ensures that the mix remains intact under varying thermal conditions. Secondly, a high density is necessary to resist thermal conductivity and minimize heat loss. This helps maintain the desired temperature in the refractory lining. Thirdly, low porosity is crucial to reduce the penetration of molten metals or slag, enhancing the durability of the installation. Additionally, good mechanical strength is required to withstand stresses and loads, preventing physical damage. The mixes should also exhibit chemical resistance to protect against corrosive substances. Furthermore, they should be easy to install and work with, allowing for efficient installation. Lastly, a controlled setting time is important to allow for proper placement and consolidation. Overall, these properties contribute to the performance and longevity of the refractory lining in high-temperature applications.

- Q:How do monolithic refractories withstand the thermal cycling in coke oven applications?

- Monolithic refractories are able to withstand the thermal cycling in coke oven applications due to their high thermal shock resistance and low thermal conductivity. They have a unique composition and structure that allows them to expand and contract without cracking or spalling under extreme temperature fluctuations. Additionally, their dense and homogeneous structure minimizes heat transfer, allowing them to maintain their integrity and strength even in the harsh conditions of coke oven operations.

- Q:How do monolithic refractories resist chemical corrosion in iron and steel applications?

- Due to their unique characteristics and composition, monolithic refractories demonstrate high resistance to chemical corrosion in iron and steel applications. This resistance is attributed to various factors. One crucial factor is the utilization of top-notch raw materials. Typically, monolithic refractories are crafted from high-alumina or alumina-silica aggregates, which possess excellent resistance to chemical reactions. These aggregates are carefully selected to withstand the harsh conditions encountered in iron and steel applications, including exposure to molten metal, slag, and various chemical compounds. Furthermore, the binders employed in monolithic refractories play a vital role in their resistance to chemical corrosion. Common binders encompass clay, calcium aluminate cement, or colloidal silica. These binders not only hold the refractory materials together but also provide extra protection against chemical attack. They create a dense and impermeable structure, preventing corrosive substances from penetrating the refractory lining. Additionally, monolithic refractories often incorporate additives that enhance their chemical resistance. These additives, comprising antioxidants, anti-spalling agents, and various compounds, further safeguard the refractory lining from chemical attack. They neutralize corrosive elements, inhibit the formation of harmful compounds, and reduce the overall corrosion rate. Moreover, the unique installation method of monolithic refractories also contributes to their resistance to chemical corrosion. Unlike traditional brick refractories, monolithic refractories are installed as a single, continuous lining. This eradicates the need for joints or gaps that could potentially serve as weak points for chemical penetration. The monolithic nature of these refractories ensures a tight and seamless lining, reducing vulnerability to chemical attack. In summary, the combination of high-quality raw materials, effective binders, and beneficial additives, along with the monolithic installation technique, endows monolithic refractories with exceptional resistance to chemical corrosion in iron and steel applications. This resistance enables them to endure the harsh conditions encountered in these industries, ensuring the durability and efficiency of the refractory lining.

- Q:What are the factors influencing the choice of monolithic refractories for different furnace types?

- There are several factors that influence the choice of monolithic refractories for different furnace types. Firstly, the operating temperature of the furnace is a crucial factor as different monolithic refractories have different temperature resistance levels. Secondly, the type of material being processed in the furnace is important as certain materials may require specific refractories to withstand their corrosive or abrasive nature. Thirdly, the furnace design and its heating method also play a role in determining the suitable refractory material. Additionally, the thermal conductivity, thermal shock resistance, and mechanical strength of the refractory are considered to ensure optimal performance and durability. Finally, cost, availability, and installation requirements are factors that can influence the choice of monolithic refractories for different furnace types.

- Q:What are the specific requirements of monolithic refractories for steel ladle purging applications?

- Monolithic refractories used in steel ladle purging applications have specific requirements to ensure optimal performance and durability. Firstly, these refractories need to have high thermal stability and resistance to thermal shock due to the extreme temperatures involved in the steelmaking process. This is important to prevent any cracking or spalling of the refractory lining. In addition, monolithic refractories for ladle purging applications should have excellent corrosion resistance against molten steel and slag. They need to withstand the aggressive chemical environment without any significant deterioration, as this could lead to contamination of the steel and affect its quality. Another important requirement is good erosion resistance. The refractories should be able to withstand the high velocity of the purging process, where argon or other gases are injected into the ladle to remove impurities. This erosion resistance ensures that the refractory lining remains intact and does not wear away during operation. Furthermore, monolithic refractories for ladle purging applications should have low porosity and high density. This prevents the penetration of molten steel and slag into the refractory lining, reducing the risk of thermal spalling and corrosion. Lastly, these refractories should have good thermal conductivity to efficiently transfer heat from the steel to the refractory lining, allowing for better temperature control and energy efficiency during the purging process. Overall, the specific requirements of monolithic refractories for steel ladle purging applications include high thermal stability, corrosion resistance, erosion resistance, low porosity, high density, and good thermal conductivity. Meeting these requirements ensures the refractories can withstand the harsh conditions of the steelmaking process, maintain their integrity, and contribute to the production of high-quality steel.

- Q:How do monolithic refractories improve the performance and efficiency of iron and steel production?

- Improved performance and efficiency in iron and steel production are achieved through the utilization of monolithic refractories. These specialized materials are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, making them ideal for high-temperature industrial processes. A key contribution of monolithic refractories is their ability to provide a protective lining for furnaces, kilns, and other equipment used in iron and steel production. Their superior heat resistance ensures that the underlying structure is shielded from the intense heat, preventing any detrimental effects on the equipment. This results in reduced downtime, extended service life, and ultimately, enhanced overall efficiency. Furthermore, monolithic refractories play a crucial role in improving thermal efficiency during the production process. By minimizing heat losses, these materials help maintain a stable and uniform temperature distribution, thereby enhancing the energy efficiency of the system. Precise temperature control is of utmost importance in iron and steel production to achieve the desired metallurgical properties of the final product. Additionally, monolithic refractories exhibit excellent resistance to chemical corrosion, erosion, and slag attacks. They act as a barrier between the molten metal and the refractory lining, preventing unwanted reactions and material degradation. This preserves the integrity of the furnace lining, reducing the need for frequent repairs or replacements. Consequently, it leads to increased productivity and long-term cost savings. Moreover, the ease with which monolithic refractories can be shaped, repaired, or replaced is another advantage. Unlike traditional brick refractories, which require labor-intensive and time-consuming installation, monolithic refractories offer a more flexible and efficient application. Their flexible nature allows for easy repair of damaged areas, minimizing downtime and ensuring uninterrupted production. In summary, the utilization of monolithic refractories significantly enhances the performance and efficiency of iron and steel production. These materials provide a protective lining, improve thermal efficiency, resist chemical corrosion, and offer easy installation and repair options. By optimizing the production process, monolithic refractories contribute to higher productivity, reduced downtime, and increased cost-effectiveness in the iron and steel industry.

- Q:Can monolithic refractories be used for the lining of continuous casting tundishes and molds?

- Yes, monolithic refractories can be used for the lining of continuous casting tundishes and molds. Monolithic refractories are versatile and can be shaped or molded to fit the specific requirements of the tundish and mold lining. They offer excellent thermal shock resistance and high-temperature stability, making them suitable for the harsh conditions of continuous casting. Additionally, monolithic refractories have low porosity, which helps prevent the penetration of molten metal and promotes longer service life for the tundish and mold lining.

- Q:What are the key properties of pumpable refractories used for monolithic refractory applications?

- The key properties of pumpable refractories used for monolithic refractory applications include high flowability, good workability, excellent bonding strength, and high resistance to thermal shock. These pumpable refractories should also possess good pumpability and be able to withstand the intense heat and mechanical stress in the application environment. Additionally, they should have low water demand, high chemical resistance, and the ability to maintain their properties even after exposure to high temperatures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ladle Shroud long nozzle Chinese steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords